- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Jacopa Ltd

Overview

Products

Megadyne is one of Europe’s leading manufacturers of timing belts and pulleys. Our products are known throughout the continent and right across the globe for their exceptional quality, reliability and performance, even when subject to the most difficult operating conditions.

An ongoing policy of research and development into new materials and new manufacturing techniques has kept us at the very forefront of transmission belt technology for more than 50 years. Ever since its establishment back in 1957, Megadyne has been developing innovative products to meet the changing needs of a continually evolving industry.

The quality of our products is unrivalled anywhere in the market. Our designs are thoroughly tested during research and development, and our production facilities are constantly monitored under an approved quality auditing system.

Some of our transmission technologies are detailed in the sections below. For more information, please visit Megadyne online, where product datasheets are available for download. If you have any further questions, please do not hesitate to call. Megadyne’s UK office can be reached on 01384 215021.

Membrane Bioreactors (MBR)

We use efficient, cost-effective wastewater treatment systems such as the membrane bioreactor (MBR). MBR systems are suitable for permanent installations as well as temporary deployable use, to support routine maintenance programs or overloaded and failing sewage treatment processes. The MBR Technology™ has widely become an important processing tool in the treatment of waste liquids. Our Enviroquip® and Copa® MBR systems are straightforward to use and combine clarification, aeration and filtration procedures into a process that reduces capital and operating costs. Submerged Membrane Units (SMU) are connected within the MBR system and contain one or two membrane cassettes with between 25 and 208 membranes to form a permeate manifold. Our MBRs have the highest effluent quality and are structured with a biological process that virtually eliminates pollutants such as Biochemical Oxygen Demand (BOD), nitrogen and phosphorous.

Rotating Biological Contactors (RBCs)

Our environmentally friendly, rotating biological contactors (RBCs) are designed to the highest of industry standards. They offer a fantastic 20-year design-life and are designed to meet our clients' requirements. For use in domestic sewage and industrial effluent treatment plants, our RBCs are driven by power motors to remove soluble, biodegradable, organic materials from domestic and industrial wastewater. The result is a final effluent that is safe for discharge. We supply RBC Package Plants, Semi-Modular RBCs and Modular RBCs. For further details on our technology, please visit our website or contact us at Jacopa Ltd.

Water ReUse / Tertiary Filtration

Jacopa has become renowned across the wastewater industry for our sustainable, effective and reliable tertiary wastewater treatment solutions and innovative water reuse technology. Our standard tertiary SAF is very simple to operate, requires minimal maintenance and is remarkably versatile. Furthermore, our team of highly experienced engineers are capable of tailoring SAF plants from our standardised range to meet individual customer specifications. The solution is suitable for both permanent and temporary schemes, above and below ground installations and for municipal and industrial use. Jacopa also offers the potential for water reuse. Our advanced membrane bioreactor (MBR) solution can reduce COD and nutrient levels far below those achieved by conventional biological treatment or retrofitted Ultra Filtration alone. The MBR is ideal for providing highly treated water for agricultural or horticultural irrigation.

Dissolved Air Flotation

Jacopa's innovative Dissolved Air Flotation (DAF) system is a compact clarification process for the primary treatment of potable water and tertiary treatment of wastewater. Our DAF systems provide the ideal solution for water, food and other industries where wastewater frequently carries large volumes of low-density solids which are unsuited to settling. One of the greatest advantages of our DAF systems is their compact size. In fact, they occupy 25% less space than any settling methods. If you would like to find out more about DAF and the solutions that Jacopa provides, please visit our website where you can download a file containing all of the technical specifications.

Mobile Systems

Our diverse range of "plug and play" mobile wastewater treatment plant solutions are ideal for locations where users often need to ensure that their environmental impact is minimal. They are highly suited to military field operations, aid relief and construction sites. All products in this range require minimal operator input and are easy to install and maintain. Our highly experienced team are ready to advise on which of our durable, ready-to-use systems is best suited to your individual needs. Jacopa also offers a variety of shipping options for ease of transport.

Submerged Aerated Filter (SAF)

After nearly twenty years of development, Jacopa's Copa Submerged Aerated Filter (SAF) has a proven performance record that is unrivalled within the industry. The Copa SAF system is a fixed film biological treatment unit that is ideally suited for treating municipal and industrial wastewaters. Our SAF installations have been supplied to industries worldwide and have gained recognition for their immediate effect on BOD reduction. They are available for purchase or hire and can be applied to a wide range of treatment applications including roughing and BOD/ammonia removal. If you would like to find out more, please follow the link.

Jacopa Spiral Screen

The Jacopa Spiral Screen is designed for the removal of fine solids. The shaftless spiral design elevates the collected screenings up and out from the effluent flow. We recommend this system for treating flows up to a maximum of 300 l/s. These high-quality and extremely reliable systems are available in 304L or 316L stainless steel. For more information including a downloadable file which contains a full list of specifications, please visit our website.

Parts OEM

At Jacopa, we aim to ensure all of our customers get the very best operational performance from our products. We put considerable time, thought and effort into the design and manufacture of our equipment. One of the keys to our success in the wastewater industry, however, is our extensive inventory of OEM replacement parts. We aim to provide parts that are the same or equivalent to those provided when the asset was first assembled and our knowledgeable aftermarket parts and service team are at hand to offer complete life cycle support. Significant benefits of this approach include superior quality, higher reliability and performance, traceability and consistency of sourcing, high value and on-time delivery.

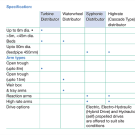

Filter Distributors

Jacopa's Filter Distributors have been expertly designed to evenly distribute sewage over a trickling filter. They are widely regarded as the most flexible and resilient method of biologically treating wastewater. At Jacopa, we pride ourselves on our ability to cater to all customer requirements and as such can offer a range of drive mechanisms to suit intermittent, low or continuous high flow conditions up to 50 metre bed diameters. To find out more about our high-quality Filter Distributors, please visit our website or contact us.

Jacopa GPS Overflow Screen

The Jacopa GPS Overflow Screen is an ideal solution for the removal of floating debris prior to storm storage tanks or discharge into rivers. It can be fabricated to suit a variety of weir overflow lengths. The design features brushes mounted on the screw to ensure thorough cleaning of the filter basket holes and the passage of water. The screens are available in 304L and 316L stainless steel and can provide screening from 3mm to 8mm to suit all specific requirements.

COPASAC Screen

The CopaSac Screen has a modular design that can be made to fit into most sewage treatment applications. It can be installed directly into the flow of the path of the fluid being screened. This highly reliable screening system uses disposable sacks that are capable of retaining any solids which may otherwise cause downstream problems such as pollution of surface waters. It can provide screening down to 3mm and is very easy to retrofit. To learn more, follow the link which will direct you to a downloadable form detailing all technical specifications.

Screw Compactor

The Jacopa Screw Compacter features a 9mm thick drainage trough for increased durability and 6mm tapered holes for optimum drainage. It has been designed and manufactured with lowering life cycle costs in mind and incorporates the original Jones+Atwood technology that has become renowned within the industry for its record of reliability and robustness. The Jacopa Screw Compacter is available in 5 standard sizes to suit different requirements and is built with mild steel as standard.

Washer Compactor

Jacopa also offers the highly reputable Jones+Atwood Washpactor-Jet System. They have been purposefully designed to wash screened solids prior to final compaction and are capable of eradicating much of the faecal matter that would otherwise foul the dewatered waste product. These rugged screenings can be delivered to the Washpactor by conventional conveyor system or the launder method. They are available in 4 standard sizes and capacities of 1.8-24.0 m3/hr. Please visit our website to find out more.

Vortex Grit Treatment

Available in 10 standard sizes, the Jones+Attwood Jeta grit trap is a high performance, compact grit removal unit. It features a specially designed impeller, which, together with its sloping sides helps to provide maximum separation of heavy mineral solids while rejecting unwanted organic solids. These extremely reliable traps have a capacity of up to 3000 l/s and are available with airlift or pumped method of grit extraction. Customers can choose between machines in painted mild steel, 304L or 316L stainless steel. Diameters range between 1.8-7.3 metres and collector chamber depths from 2.8-6.6 metres.

Polyurethane Timing Belts

Our polyurethane timing belts are known for their exceptional versatility; they can be used in many different applications. Produced with Megapren Polyurethane, Megadyne timing belts are highly resistant to wear and tear and have extremely hardwearing traction cords made from steel (these give the belt excellent dimensional stability). They are practically noiseless, highly flexible, resistant to chemicals and extreme temperatures, and require very little in the way of maintenance. A combination of good mechanical and chemical characteristics make Megadyne polyurethane timing belts suitable for high-revolution applications in all kinds of operating conditions.

Open-End Belts

Megadyne has been producing open-end belts for more than 35 years of its 56-year history. These days they are produced with thermoplastic polyurethane, which gives superior wear and abrasion resistance. They also feature steel cords of various grades for excellent running characteristics even when subject to high tractive load. Megalinear belts (the name for our open-end belts) are ideal for applications where accuracy of positioning, low noise and zero maintenance are required, such as in conveyors and elevators.

Belts can be manufactured according to individual customer requirements. Get in touch to find out more.

Custom-Made Pulleys

Megadyne also specialises in the design and manufacture of pulleys. These can be produced to almost any specification, with the tightest tolerances for exceptional accuracy. A variety of protective and anti-corrosive surface treatments can be also be applied. Customers can choose from a range of standard and special designs. To discuss your requirements with an industry expert, just give us a call on 01384 215021.

Isoran RPP Silver Timing Belts

Our innovative Isoran RPP Silver timing belts are made with the highest quality materials, ensuring the highest standard of quality and performance anywhere in the industry. Features and benefits include:

- A special compound body increases resistance to tooth sheering, even in the presence of rapidly varying load.

- A fibreglass cord assures breaking load at maximum levels, with extremely reduced elongation coefficients.

- Hardwearing nylon fabric bonded to the tooth surface improves torque carrying capacity.

- Belt design increases load carrying capacity by up to 10% compared to the previous RPP Plus.

Find out more by visiting Megadyne online, where product datasheets can be downloaded in PDF format.

Isoran RPP Gold Timing Belts

Our Isoran RPP Gold belts have many of the same features as our RPP Silver belts, but are capable of performing to a much higher level thanks to their superior tension stability, even better resistance to tooth shear and flex fatigue, and their higher level of protection against ozone, oil, grease, heat and sunlight. Like our RPP Silver belts they are made with the very best materials and are specially bonded for exceptional torque capacity. Please download our product catalogue for more information on our RPP range of timing belts.

V-Belts

Megadyne’s V-belts are manufactured from a polybutadiene compound that has an operating temperature range of -30°C to +70°C, and which offers excellent resistance to oil, grease and ozone. Polybutadiene also has good antistatic properties.

Our V-belts are highly efficient, require little maintenance, can be driven at a range of speeds, and do not require lubrication. They are also silent, smooth starting and smooth running. Megadyne V-belts are available in a variety of sizes to cover most industrial applications. Special sizes can be made to order.

PV V-Ribbed Belts

High performance poly V-ribbed belts can be produced in H, J and L profiles. PV belts are designed to:

- Eliminate belt matching.

- Meet the exact power or space requirements of the drive.

- Distribute drive load across the entire belt width.

- Allow cooler running.

- Improve high drive efficiency.

This type of belt excels on small pulleys at high speeds.

PV V-ribbed belts are also available in elastic versions. For more information, please visit Megadyne online or contact us on 01384 215021.

Manuals & Brochures

Details

Info

| Registration Number: | 09352099 |

| VAT Number: | GB863 3544 15 |

| Registered at Companies House: | 12 December, 2014 (9 years and 4 months ago) |

| No of Employees: | 1001-5000 |

| Annual Turnover: | n/a |

| Parent Company: | GEDA Construction |

| Importers: | |

| Exporters: | |

| Company Type: |

|

| UK Branches: | Chippenham, Colchester, West Bromwich, Wolverhampton & Kent |

Opening Times

| Monday | 08:30 AM - 05:30 PM |

| Tuesday | 08:30 AM - 05:30 PM |

| Wednesday | 08:30 AM - 05:30 PM |

| Thursday | 08:30 AM - 05:30 PM |

| Friday | 08:30 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Brand & Trade Names

- Brackett Green Coarse Screens - Eimco Water Technologies manufactures a wide range of coarse Bar Screens, including the well known brands, Brackett Green, Copa Tomkinson and Jones & Attwood. Coarse Bar Screening provides the initial protection for headworks and water intakes with aperture sizes ranging from 10mm to 200mm. Bars can be fixed or rotating elements to preventing ragging.

- Copa CopaSAF, Copa Cyclone, Copa Crosswave Screen, Copacurve, CSO storm screens and process equipment

- Crossflow Detritor™ System The Crossflow grit separator is used at the raw sewage inlet and should be positioned downstream of the sewage screens. These screens will have medium to fine spaces. Where two stage screening is applied, the Crossflow Detritor™ system can be installed after the medium spaced screen thus offering protection to the fine screening mechanism from abrasive detritus.

- Eimco CSO Screens, Combined Sewer overflow screens, Storm overflow screens. Most combined sewerage networks will incorporate emergency overflow or discharge points along its length, to overcome excessive surcharging of the network. These are commonly referred to as Combined Sewer Overflows or CSO’s. The CSO’s are designed to allow excessive stormwater flows to spill into open/surface water courses. To prevent unsightly debris polluting the receiving water course Eimco Water Technologies has developed a range of CSO screening solutions to suit almost all types of CSO locations and stormwater retention tanks.

- EWT - Eimco Water Technologies Thickeners - Combining the industry's highest quality craftsmanship and materials with experience, EWT designs and builds a variety of thickeners for all water and wastewater applications.

- EWT™ Clarifiers The EWT™ Clarifiers are easily adaptable to special designs. In addition to standard optional features, our engineers will design and develop new features necessary to satisfy special application requirements. This may necessitate concepts never before incorporated in a clarifier, or may combine features in a new configuration. Whatever the special requirement of the installation, we will provide a design to suit user needs. Options readily available include but are not limited to: Column Supported Mechanisms for Tank Diameters to 104 Feet, Corner Sweeps, Spiral Rake Blades, Flocculation Equipment with Large, Diameter Feedwells, Rotating Sludge Collection Drum, Surface Skimming Equipment to Meet any Application, Rapid Sludge Return Systems, EDI - Inlet Design. Bridge Supported Mechanisms for Tank Diameters up to 50 Feet Customized designs to match unique specifications, Corner sweep clarifiers - for square basins, Large diameter feedwell clarifiers with EDI design - for improved performance, Flocculator clarifiers - for improved settling, Special designs - for unique applications. Skimming mechanisms, EWT™ ClariThickener - sludge thickening and clarification in a single basin, Dependable clarifier driveheads - designed for maximum duty service

- EWT™ Digester Digestor Covers - Eimco Water Technologies provides a variety of digester covers for your specific applications. EWT™ Digestion Equipment as the anaerobic digestion process has developed; Eimco Water Technologies has become a leader in the field, providing technology, engineering and equipment design. EWT™ Digester Covers are constructed as a dome-shaped segment of a sphere, offering maximum strength and structural integrity.

- EWT™ Package MBR The EWT™ Package MBR unit is the first below ground wastewater treatment package plant developed by Eimco Water Technologies to incorporate their proven membrane bioreactor (MBR) process. The process provides a high quality effluent that far exceeds all current and future envisaged standards.

- HBNR - Hybrid Biological Nutrient Removal With 600 Installations world wide, the Hybrid BNR Process offers proven economical and reliable treatment of wastewater, particularly where low Nitrogen and Phosphorus limits are required. The process combines the performance benefits of conventional continuous flow processes incorporating anoxic and aerobic reactors, with the simplicity and cost benefits of SBR’s (sequencing batch reactors).

- Headworks - Preliminary Treatment Technologies Good preliminary treatment (screening and screening handling of gross solids and grit removal) are as important to the efficient operation of any treatment plants as is the process means selected to treat the wastewater itself. Eimco Water Technologies has an established range of brand products for headworks and inlet works treatment, inclusive of Brackett Green and Jones & Attwood.

- J + A - Jones + Attwood Inclusive of J + A Screens, washer compactor, washpactor, tipping buckets

- Jeta .Jeta Grit removal combined with screening is a prerequisite of wastewater treatment to make the ongoing effluent a manageable and consistent medium entering the next phase of treatment. Ideally, screening or comminution of the main flow will be performed prior to grit removal. In cases where grit is removed from entirely raw sewage, additional washing and classification is necessary before dewatering. The Jeta grit trap is designed to provide the highest grit removal performance possible.

- Jones & Attwood Grit Washer The demand for cleaner and biodegradable free waste products is growing with the introduction of increasing legislation from governing bodies. Historically, grit from sewage has always had demands made upon it with respect to an organics content. Good attempts have been made to achieve the best possible separation but, in reality, few operating plants are successful. By developing the new concept to produce a consistently clean grit, other spin-off benefits are realised.

- Jones & Attwood Screw Classifier Screw Classifier is a packaged, free standing system, for the separation of mineral grit particles from the normal collections of solids and water, discharged by grit removal systems.

- MBBR Eimco Water Technologies has wide experience with different types of biological treatment methods. Within this field our key technology is an advanced, high-loaded biological treatment method called FlooBed®. It is a biological treatment of industrial process or waste waters. The biology consists of micro-organisms both attached to the carriers and suspended in the water. The FlooBed® solution has been the choice for several types of water such as effluent from process industries, landfill leachate and municipal waste waters.

- MBR Technology Membrane bioreactor. Membrane Bioreactors (MBR) have been successfully used to treat municipal, commercial and industrial wastewaters for discharge and reuse applications. Today, with thousands of installations operating worldwide, MBR technology is shaping the way we view wastewater treatment and water conservation around the world.

- Rake Classifiers The Rake Classifier consists of a reciprocating rake mechanism set in an inclined channel alongside the grit collection basin. The smooth agitation of grit caused by the low speed motion of the rake mechanism provides a perfect environment for the settled grits to liberate putrescible organics, leaving clean grit for discharge and reduced odour problems

- RBC - Rotating Biological Contactor A Rotating Biological Contactor (RBC) is a process used to remove soluble, biodegradable, organic materials from sewage thereby achieving a high quality effluent. There are three types of plant: (i) Package plant (Integral), (ii) Semi package Systems, (iii) Modular plant

- SAF - Submerged Aerated Filter Copa SAF Submerged Aerated Filter (SAF) is a high performance biological filter for the treatment of both domestic and industrial wastewater.

- SBR Sequencing batch reactors (SBR) or sequential batch reactors are a unique secondary aerobic biological treatment process ideally suited to many industrial applications. Typically they are designed to reduce the organic and nutrient loadings in medium strength wastewater to comply with surface water discharge limits or as a pre-treatment stage to tertiary recycling plants.

- StopGates StopGate modules, widely used on cooling water intakes, are designed to provide a water seal allowing for safe and easy routine inspection or maintenance on either the screening equipment or pump intakes downstream.

- Water Intakes Eimco Water Technologies is a leading supplier of high-performance liquid-solid and liquid-liquid separation technologies for municipal water treatment. We provide customers with innovative solutions adapted to water intake solutions. From fish protection to screening debris to protect downstream equipment.

Products & Services

Gallery

Financial Information

To view more detailed financial information for this company click here.

- External Works Contractors

- Lowtax Ltd

- Longreach Management Ltd

- Waste Oil Incinerators

- Flexographic Printing Inks

- Mkh Traffic Management Solutions Ltd

- North Eastern Powergrid Ltd

- Halliard Ltd

- RAMSAY MCGHEE TRAINING & SERVICES Ltd

- HAMPTON SCOTLAND LLP

- Pump Seals

- Hd Cctv Ltd

- The Naked Truth Ltd

- Joe's Lodge Ltd

- Trace Basement Systems

- Centrifugal Galvanising

- Cherrington Court Management Company Ltd

- Universeal (UK) Ltd

- MORDEN