- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Impreglon UK Ltd

Overview

Products

Impreglon UK Ltd is a specialist applicator of fluoropolymer and plasma coatings that are used on surfaces where there is a need for a chemical resistant, solvent resistant, impact resistant, insulated, high friction, low friction, non-stick or easy-clean surface. As well as offering a range of brand name coatings that include Teflon®, Xylan®, Greblon®, and Rilsan®, we also provide our own range unique materials such TempCoat, ChemCoat, MagnaCoat and PlasmaCoat. These are used for a wide variety of applications across a range of industrial sectors, including aerospace, chemicals, converting, engineering, food, medical, defence, oil & gas, packaging, printing and textiles. Impreglon coatings can be applied to any metallic substrate and many can even be applied to fabrics, glass and carbon reinforced plastic. Whatever surface finish you require, Impreglon has the right type of polymer or plasma to achieve it. Visit our website today to find out more about the products and services that we offer, or simply give us a call and speak to one of our experts.

Teflon® Coatings

Our Teflon coatings can be applied to a wide range of materials and offer an extensive selection of benefits. As well as being non-stick, Teflon coatings are also heat resistant, non-wetting, cryogenically stable, resistant to chemicals and possess unique electrical properties. It is worth noting that all of our coatings are applied by highly trained professionals who have a wealth of experience within the field. If you would like any more information on these or any of our products don't hesitate to visit the website.

Xylan® Coatings

We are approved to provide Xylan coatings which can be applied to many different types of surfaces. Just some of the properties of Xylan coatings include dry lubrication, wear resistance, corrosion resistance, chemical resistance and non-stick. This unique set of characteristics means that Xylan is not just effective but also incredibly versatile. To find out more information or if you have any further questions feel free to contact our customer service team directly, by phone or email.

Non-stick Coatings

We can provide an extensive range of non-stick coatings which prevent many different substances from sticking to your component. With so many non-stick coating formulations available, each with their own specific properties, we can offer a solution for a variety of applications. Customers can visit the website for further information on these or any of our products. Alternatively, if you would like to speak to somebody directly don't hesitate to contact us by phone or email.

Thermally Sprayed Coatings

We can provide specialist thermally sprayed coatings with four different application processes available. These four processes include arc spraying, flame spraying, high velocity oxy fuel and plasma coating. Each process is different and offers a unique solution to specific problems. If you would like to learn more about our thermally sprayed coatings please visit the website. Customers are also reminded that they can contact our customer service team directly if they have any specific queries.

Abrasion Resistant Coatings

Our abrasion resistant coatings can be applied to a wide range of materials to improve their surface hardness. Modifying the surface hardness of a components will improve its resistance to abrasion and therefore its lifespan, saving you time and money. You can visit the website for further information on this or any of our products and services. Customers can also contact us directly by phone or email and we can answer any specific questions you may have.

Corrosion Resistant Coatings

Our corrosion resistance coatings protect materials from potentially damaging substances. We can offer a wide selection of coatings including DeltaMKS, TSA, ZTD, Halar and Tefcel. Our corrosion resistant coatings are utilised by a wide range of industries which include the chemical, petrochemical, oil and gas sectors, as well as others. Customers can visit the website for further information on these or any of our products and services. Alternatively, you can contact our customer service team directly.

Dry Lubrication Coatings

Thanks to many years of experience which has allowed us to gain a wealth of knowledge within the field, we can provide solutions to a range of sliding and low friction applications. Our dry lubrication coatings can be applied to a variety of different materials, reducing their friction and allowing a greater ease of movement. Customers can visit the website for further information including detailed technical specifications on all of our coatings.

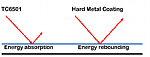

Energy Absorption Coatings

Our energy absorption coatings benefit from many unique features, including a non-toxic formulation, sound deadening capabilities, unlimited compression resistance and they have been designed to withstand up to 10,000 hours of salt spray. It is also worth noting that these coatings are available in a range of colours and shore hardiness’, to suit a variety of applications. If you have any more questions or you would to speak to someone directly, feel free to give us a call.

Halar® Corrosion Resistant Coatings

Our Halar corrosion resistant coatings do not only protection against corrosive materials but also abrasive materials and high temperatures. Halar coatings can be utilised for a wide range of applications thanks to a unique design which means they are hydrophobic, low friction, insulated against electricity, flame resistant and incredibly durable. It is worth noting that these coatings are also incredibly smooth and can therefore be spark tested at 5kV as pinholes are unlikely to develop.

Hardness Coatings

The hardness of a component can be incredibly important when it comes to factors such as durability and lifespan. Our hardness coatings include both ceramic and metallic variations which can be applied to a wide range of materials. It is worth noting that this process can be used to repair a component or just to increase its hardness and therefore resistance to wear and abrasion. We can also apply hardness coatings which have been impregnated with a non-stick material, if required.

HVOF Coatings

Our HVOF tungsten carbide coatings are particularly useful as they can be machined thanks to a dense surface. This dense coating is achieved by applying the HVOF material to the component at supersonic velocity. The unique properties of this specific coating makes it ideal for use with components such as drilling tools, offshore downhole tools, control valves, pulleys, drums and valve balls, as well as much more. Customers can visit the website for further information on these or any of our products.

Low Friction & Sliding Coatings

Fluoropolymers have many unique attributes but what makes them so useful as materials for coating is their low friction and sliding properties. This being said, it is important to utilise the right coating for the specific application at hand and this is where we come in. Thanks to many years of experience within the field, we have the expertise and resources to provide solutions for every permutation. If you would like more information on our low friction coatings please visit the website or you can contact us directly.

MagnaCoat®

The MagnaCoat coating is a strong and durable material which benefits from being pinhole free. Just some of the properties that MagnaCoat coatings possess include, a high electrical resistance, impact resistance, corrosion resistance and a non-stick surface. MagnaCoat can be used with a wide variety of metallic materials, including steel, stainless steel and aluminium. Customers can visit the website for further information, including technical details and product features.

Optical Coatings

Optical coatings can be applied to products such as safety glasses, visors and lenses in order to gain a corrosion and abrasion resistant coating which is also transparent. Another important property of optical coatings is that they are anti-fog which is obviously useful when dealing with components such as lenses. It is worth noting that these coatings can also be utilised within the automobile industry with components such as switches, lighting and external trim. To find out more, feel free to visit the website or alternatively, you can contact us directly.

PlasmaCoat®

PlasmaCoat is a material which benefits from both wear resistance and a non-stick surface. With so many variants available, customers have the option to choose a coating that is not only effective but also tailored to the application at hand. Another upside to utilising PlasmaCoat is that it is particularly good for coating cylindrical components as an accurate coating thickness can be achieved. Customers can visit the website for further information on this or any of our products or services.

Powder Coatings

Electrostatic powder coatings differ from the more conventional products but can provide a wide range of benefits. For example, powder coatings are completely environmentally friendly as no harmful by-products are released during their production. As well as being extremely high quality, powder coatings also incredibly economical which helps our customers to save money. If you have any further questions about these coatings or would just like to speak to someone directly, don't hesitate to contact our customer service team.

Traction Coatings

Traction coatings are materials which utilise a variety of different coating types and application processes. These combination based products can offer unique and extremely useful characteristics. The main benefit of traction coatings is that movement is much smoother, especially involving materials made from plastic, paper and fabric. One of the most popular traction coatings is PlasmaCoat, with customers able to choose from a range of different roughnesses. For further information feel free to visit the website or you can contact us directly.

TempCoat®

Our TempCoat coatings have been designed with many features in mind, including non-stick, dry lubrication, sliding and release properties. Just some of the materials that can be coated using our TempCoat method include, steel, stainless steel, aluminium, castings, copper alloys and ceramics. It is also worth pointing that when using specific types of TempCoat processes, materials such as glass fibre, carbon fibre and some plastics can be coated too. To find out more please visit the website or you can contact us by phone or email.

Manuals & Brochures

Details

Info

| Registration Number: | 02028357 |

| VAT Number: | n/a |

| Registered at Companies House: | 16 June, 1986 (37 years and 10 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: |

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Products & Services

Gallery

Financial Information

To view more detailed financial information for this company click here.

- KNIGHT LANGLEY LTD

- Vericare (UK) Ltd

- DME TRANSPORT LTD

- Pauline & Edward Healthcare Ltd

- Gtl London Ltd

- MERSEYSIDE

- Forklift Truck (FLT) Operator Training

- Lighting Columns

- A & J Dental Laboratory Ltd

- security roller shutters

- Alexander Plumbing & Drainage

- F. Swain & Sons (Holdings) Ltd

- GLOBAL FOOTBALL PRO (UK) Ltd

- Nylon Resins

- UID Data Matrix Marking

- Standby Solutions Ltd

- Wire Rope Assemblies

- CATOR ROAD LLP

- Abee Hire Ltd