- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Riggs Autopack Ltd

Overview

Products

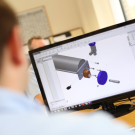

Riggs Autopack Ltd specialises in the design and manufacture of high quality volumetric depositors and filling machines, transfer pumps and automatic conveyor filling lines to companies in the food production industry.

All of our products, machines and systems are designed and manufactured at our Lancashire factory by our team of highly skilled and experienced engineers. We supply equipment to small start-up businesses through to large multi-national groups and international factories. We provide all customers with the same high standards of care from the point of initial enquiry through to post sale support and advice. We strive to create machinery of the highest standards and are pleased to be ISO 9001:2008 registers with BenchmarQ ‘Gold’ customer satisfaction accreditation. We are also a Rolls Royce plc approved supplier and members of the PPMA.

Alongside our standard ranges of machinery we also offer a bespoke service whereby we tailor existing designs and systems to meet specific customer requirements. We have many years of experience in the industry in order to provide customers with first class results. Please read on to find out more about our products and services. Or, alternatively, please follow the link to our website to view images and further information.

Micro-Fill Table Top Depositor

Here at Riggs Autopack Ltd we are pleased to supply the Micro-Fill Table Top Depositor. This semi-automatic table top depositor provides a single deposit range of 3ml – 80ml per cycle (this depends on the barrel size). It fills a wide range of containers such as jars, bottles, pots, tubs, foils, pouches and shaped moulds. The Micro-Fill table top depositor is suitable for small to medium scale food producers and is hygienic and easy to clean. It features a 15 or 25 litre hopper with a 1inch tri-clover outlet and a depositing nozzle to ensure clean cut-off.

Table Top Depositor With Conversion Kit

We also offer our table top depositor with a bench to floor conversion kit. This is available as a fixed frame unit or a mobile frame with lockable castors to suit customer requirements. This table top depositor is a low level, semi-automatic filling machine featuring a 40 litre hopper, foot pedal and extended swan neck pipework. It also comes with a choice of depositing nozzle to suit your product/ application type.

Option 1 Depositor / Filling Machine

Specifically designed to meet the requirements of food producers of a small to medium scale, our Option 1 semi-automatic filling machine helps to improve production rates. Operated via the use of a foot pedal, the Option 1 can deposit both hot and cold liquid, semi-liquid and suspended solid products accurately and free of damage. It can fill almost all varieties and size of container including bottles, pots, jars, trays, tubs, buckets, cartons, bags and pouches. With a deposit range of up to 5000ml per cycle, the Option 1 also features a construction of fantastic quality with 316 stainless steel in all product contact areas.

Option 2 Depositor / Filling Machine

The Option 2 Depositor / Filling Machine is an automatic conveyor depositor ideally suited for medium to large scale producers. It can also, however, be supplied as a semi-automatic filling machine with a foot pedal operation when required. Suitable for almost all types and sizes of container, the Option 2 provides highly accurate and damage free depositing of liquids, semi-liquids and suspended solids, whether they are hot or cold. Requiring a compressed air supply, the Option 2 is pneumatically operated whilst also featuring completely adjustable depositing volumes and speeds. Available to purchase, lease purchase or hire, the Option 2 is hygienic, easy to clean and maintain, and user-friendly.

Option 3 Depositor / Filling Machine

The Option 3 Depositor is one of our best selling machines and is widely used by medium to large scale producers as an automatic conveyor depositor. It can also be supplied as a semi-automatic filling machine with foot pedal operation. The Option 3 Depositor is designed to accurately fill a range of containers including jars, bottles, pots, tubs, trays, cake tins, foils, buckets, jerry cans, pouches and bags. This mobile unit features lockable castors to secure in place and is hygienic and easy to clean. It has a deposit range of 3ml – 5000ml per cycle and a 40 litre hopper with two inch tri-clover or three inch RJT outlet.

Pouch Opening & Filling Machine

Here at Riggs, we are pleased to offer our fantastic pouch and bag filling machines. These provide users with damage free depositing of hot and cold liquid, semi-liquid and suspended solid products. Our machines have been expertly designed and created to accurately fill plastic pouches, bags, sacks and thermo-form containers. They are widely used in the industry for the following applications: Honey, Preservers, Condiments and Sauces, Pate, Dips and Spreads, Soup and Ready Meals, Bakery, Dairy and Seafood.

Pouch Opening, Filling & Sealing Machine

An off-line semi-automatic filling machine, our Pouch Opening, Filling and Sealing Machine is able to open, fill and seal plastic pouches of the stand-up variety, with both hot and cold liquids as well as semi-liquid products. Suitable for medium to large scale operations, each machine is built to order with the exact conical pouch opening unit to suit the requirements of your chosen pouch. Requiring only one operator, this hygienic and easy to clean machine features 316 stainless steel in all areas that come into contact with your products. It is also highly mobile thanks to the lockable castors and levelling feet.

Bag Filling & Sealing Machine

We also offer a fantastic range of bag filling and sealing machines. These semi-automatic machines feature a deposit range of up to 5,000ml per cycle and are designed to accurately fill/ seal large plastic bags. They are suitable for use with hot or cold liquid, semi-liquid and suspended solid products. Other features include an incorporated heat sealing unit, a choice of depositing nozzle to suit, optional heat guard shroud, multi-cycle counters, foot pedal, height adjustable filling table, product hopper or linked direct to holding tanks/ cooking vessels.

Bag Filling Machines

Able to fill large plastic bags, bags-in-boxes and pergal bags with accuracy, Riggs Autopack's Bag Filling Machines can deposit up to 5,000 ml every cycle. Suitable for both hot and cold liquids as well as semi-liquids and suspended solids, these machines can be operated by a single user and can be directly linked to cooking kettles or holding tanks. We make all of our bag filling machines to order in order to provide you with the exact depositing nozzle to meet your requirements as well as a variety of options such as neck grips, heat guard shrouds, multi-cycle counters, hight adjustable tables and foot pedals.

Sachet Filling Machines

Sachet Filling Machines from Riggs Autopack are fully automatic and provide fantastically accurate depositing of hot and cold liquids plus semi-liquid and suspended solid products. In order to meet the specific requirements of your operation, Autopack manufactures each of these machines to order with the right depositing nozzle or nozzles for your particular product and container. These sachet filling machines have a deposit range of 3 ml to 5,000 ml per cycle and come on a mobile frame which can be set to either a high or low level. A hopper agitation system can also be supplied for products with particulates.

Pouch Filling Machine With Direct Feed

Please visit our website to find out more about our Option 1 Depositor. This semi-automatic model has been expertly designed and created to pull hot or cold liquid, semi liquid and suspended solid products direct from holding tanks and cooking kettles instead of a hopper feed system. The Option 1 Depositor is supplied with lengths of inlet food grade flexi pipework and adaptor for direct connection to the cooking kettle/ holding tank. It also features a conical pouch opening unit, height adjustable filling table and mobile frame with lockable castors.

Jar Filling

Our incredibly talented team of engineers design and build bespoke jar filling lines for damage free depositing of hot or cold liquid, semi-liquid and suspended solid products such as jam, preservers, honey, fruit, mincemeat, sauces, dips and condiments. All jar filling lines are manufactures at our Lancashire factory and are built to stringent health and safety standards. Ancillary equipment may include scroll conveyors, rotary tables, jar washer, capping machine, metal detection, air knives and labelling. Available construction options include single or multi-head filling machines, transfer pumps, conveyor lengths with optional scroll feed, guarded fill areas, gating systems, no-container/ no fill, rotary in-feed/ out-feed tables and plc control.

Bottle Filling

We also design and build bespoke bottle filling lines for damage free automated depositing of hot or cold liquid, semi-liquid and suspended solid products such as preserves, honey, condiments, ketchup, sauces, smoothies, dressings and marinades. Our machines can feature single head filling lines for small scale batch production through to multi-head filling lines for medium to large scale production. Capping machines, bottle washer, scroll conveyors are also available. Our machines are designed to accurately fill most sizes of plastic or glass bottles, including squeezy bottles.

Vertical Transfer Pump

We are pleased to supply our fantastic vertical food grade transfer pumps for the transfer of hot or cold liquid, semi-liquid, suspended solids, viscous and fragile goods. These models are straight forward to use and pump directly from tote bins, pallecons, cooking kettles or mixing vessels into low or high level hoppers and holding tanks. Our standard vertical transfer pumps feature a nominal transfer rate up to 26 litres per minute and our Maxi-Model feature nominal transfer rate up to 50 litres per minute. All vertical transfer pumps are manufactured from 316 stainless steel in all product contact areas.

Low Level Horizontal Transfer Pump

Our low level horizontal transfer pump can be easily adapted to suit low level product transfer and can be supplied as a fixed frame or mobile unit. They are manufactured from stainless steel and pump hot or cold liquid, semi liquid, suspended solids, viscous or fragile goods directly from tote bins, pallecons, cooking kettle and mixing vessels into low or high level holding tanks. They are supplied with the relevant length and width of inlet/ outlet pipework.

Slat Conveyor

We supply mobile or fixed frame type slat conveyors. These stainless steel conveyors are designed for the processing of various container types such as jars, bottles, pots, tubs, jerry cans, buckets and more. Our team of highly skilled and talented individuals create slat conveyors to suit specific customer requirements and factory layouts. Our slat conveyors can be easily integrated into existing production systems or can be supplied to join Riggs Autopack automatic filling lines.

Platen Indexing Conveyor

We offer a range of platen indexing chain conveyors that have been specially designed to handle containers that require positional accuracy when in the product depositing stage. They feature an open, hygienic design for easy cleaning and maintenance and all platens are interchangeable to suit specific container types and sizes. Other features include three meter modular construction, fixed or mobile frame, depositor stations, interchangeable platens, snap-on lid closers, spraying systems, electrical/ compressed air sockets, removable drip trays, overhead emergency stop chords and read out counters.

Capping Machines (Automatic)

We supply the industry with 1.8 and 2.8 Emerito Capping Machines to food producers in the UK and Republic of Ireland. These machines may be supplied as a single unit for integrating into existing systems or can be supplied as part of a Riggs Autopack automatic filling and capping line. Our Emerito Capping Machines automatically cap glass, PET jars, pots, tubs and bottles with metal ‘twist-off’ lids.

Emerito Model 1.8 Capper

Lid diameter - 27mm to 82mm

Lid height - 5mm to 18mm

Container diameter - 30mm to 106mm

Container height - 37mm to 250mm

Emerito Model 2.8 Capper

Lid diameter - 27mm to 110mm

Lid height - 5mm to 18mm

Container diameter - 30mm to 160mm

Container height - 37mm to 260mm

Capping Machines (Semi-Automatic)

We also supply a fantastic range of semi-automatic cap tightening machines that can be incorporated into a semi-automatic filling machine, fitted as a standalone work bench or incorporated into existing production systems. The unit features one cap head tightener to suit one size cap only – interchangeable cap heads can also be supplied. Our capping machines are designed for tightening jar, pot and bottle caps and are pneumatically operated. They are easy to clean and maintain and are tough and robust for reliable and long-term use.

Spares

The majority of our machinery is manufactured in-house which means we also stock a wide range of quality assured spares. Spares typically include:

- Air service units

- Calibration units

- Castors

- Clamps

- Depositing nozzles & decorating heads

- Food safe grease

- Foot pedals

- Hoppers & hopper lids

- Motor assembly's

- Operator manual's

- Pump barrel's

- Pipework (rigid stainless steel or food grade hose pvc / wire re-inforced)

- Rotary valve body & components

- Seals (nitrite / viton / ptfe / ptfe encaptulated)

- Tommy bars

- RJT spanners

- We can also provide on-site staff training & planned maintenance agreements

Trade Show - Come and see us

Riggs Autopack exhibits at various machinery based trade shows throughout the year. This is a great opportunity for us to meet people in the industry and showcase our fantastic products and services. Please visit our website to find out where we will be heading in 2014. We look forward to seeing you!

Decorating Heads & Depositing Nozzles

Suitable for dispensing both hot and cold liquids as well as semi-liquids and suspended solids, our huge range of decorating heads and depositing nozzles are ideal for enhancing the look of your product from puddings and desserts, to ready meals and mashed potatoes. Riggs Autopack can supply a range of standard versions plus bespoke models to exactly suit your requirements in product and container size. Manufactured to meet strict Health and Safety requirements, our decorating heads and depositing nozzles are hygienic and easy to clean. A range of options is also available including non-drip cut-offs, shearblades and lance probes among many more.

Scroll Conveyor

Riggs Autopack is fully equipped to provide bespoke scroll conveyors that are designed and manufactured to exactly suit your particular type of container and size of container. Our slat conveyors are available with a scroll feed system which enables them to deal with tricky to handle containers. Other options include a choice of fixed or variable speed drive as well as completely interchangeable scrolls which can be colour coded for each of your container sizes and profiles. Our scroll conveyors provide performance than can be depended upon with a robust and durable construction alongside a comprehensive guarantee.

PEG Indexing Conveyor

A Peg Indexing Conveyor from Riggs Autopack can be easily integrated into your existing production system and comes with an open and hygienic design, allowing for simple cleaning. These conveyors feature a modular construction 3 metres long, adjustable side-guides and base rails to enable the conveyor to accommodate containers of various sizes and shapes, and variable controls for speed, dwell time and ramp position. Our Peg Indexing Conveyors are also available with either single or twin lanes, depositor stations, dead plates for the infeed or discharge ends, container pick and place, pot droppers, spraying systems, snap-on lid closers, and read-out counters among many other options.

Manuals & Brochures

Details

Info

| Registration Number: | 05715991 |

| VAT Number: | n/a |

| Registered at Companies House: | 21 February, 2006 (18 years and 2 months ago) |

| No of Employees: | 21-50 |

| Annual Turnover: | 2-5m |

| Parent Company: | Fort Vale Group |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Company Certifications

| ISO 9001:2015 - Quality management systems – Requirements |

Products & Services

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Companies beginning with H

- Twynham Consultancy Ltd

- Industrial Brushes

- Northamptonshire Healthcare Ltd

- Next Generation Engineering Ltd

- BURREN LIFE Ltd

- PRECINCT BUILDERS Ltd

- Nolcom Communications Ltd

- CROPSURE Ltd

- The Wales Heritage Academy (Uw Press)

- NT Precision Ltd

- Installation Space Ltd

- Azalia Projects Ltd

- Blouses

- Mhg Management Ltd

- Welding Plant & Equipment

- Skip Hire, Lease, Rent

- Latches

- Fertilisers