- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Retronix Ltd

Overview

Products

Retronix Ltd is a globally respected name when it comes to the electronics industry. Companies within the Retronix family include Retronix Semiconductor Systems Ltd, Retronix Certified (Component Testing), Retronix Flexible Sourcing (Labour Supply) and Retronix RF. Retronix provides modern and innovative solutions to the electronics industry and has done so for a number of years. Our services are designed to provide businesses within the electronics sector a platform whereby they can function more efficiently and reduce production costs. We are continually evaluating and developing our ranges of services to ensure that our solutions are up to date with modern developments. We know the market inside out and provide services that we know our customers will benefit from. Our success within the global market is clear indication of the first-class service that we provide our customers. For a range of quality electronics solutions, contact Retronix.

PCB Repair

Here at Retronix we provide OEM and CEM companies worldwide with a range of PCB repair services. Our experience within the industry has enabled us to provide our customers with modern and innovative services designed to reduce manufacturing costs and improve production efficiency. As an example, we have developed a fantastic process whereby we recover high value silicon ( FPQFP, BGA, µBGA, CBGA, Lead Free BGA) from PCBAs and return it to customers at a fraction of the price that it would cost new. Companies across the world take advantage of such services in order to greatly reduce their production costs. Examples of our repair services include NGA Reballing, Component Removals, Console Repairs, and Alloy Refreshing. Please contact us for further information.

Alloy Conversion Re-tinning

Here at Retronix we provide high quality alloy conversion and automated component re-tinning services. These processes largely follow nine priority steps: Device Vacuum Pickup, Edge Flux Station, Pre-heating, Scavenging Solder Pot Side Wave, Edge Flux Station, Pre-heating and Pyrometer Temp Check, Final Solder Pot Side Wave, Solvent Wash Station then Rinse Station and Finished Device Return. Our re-tinning service is fully compliant with ANSI/GEIA-STD-006 for all components with leads, QFP, TSOP, MSOP, PTH, sockets and axials. Our automated equipment ensures that components are not exposed to re-flow or abrasion and that they are IC device safe.

BGA Recovery

We offer a fantastic BGA Recovery service saving companies large amounts of money and reducing the amount and cost of landfill. Our unique BGA rescue process uses zero re-flow cycles in a repeatable process to comply with the manufacturer’s specifications. Our eight step BGA recovery process features the following steps: Prebake, Component Removal, Solder Removal, Laser Reball, Clean, Mechanical Test, Electrical Test and Packing. Please contact us at Retronix for further information regarding our BGA recovery services and find out how we can help you.

QFP Recovery

Here at Retronix we can refurbish and remove components without using re-flow cycles or abrasive processes. Our QFP recovery process largely follows the following steps: Prebake, Component Removal, Solder Removal, Clean, Mechanical Test, Electrical Test and Packing. Our QFP recovery services are widely used over traditional methods which can use up to four re-flow cycles in total. Please contact the team at Retronix to find out more about our QFP recovery services. We provide a first class service at all times and provide all services at competitive prices.

Anti-Counterfeit IC Test RoHS Compliant

With a range of specific tests at their disposal, Retronix can identify faulty or counterfeit ICs; helping you to keep them out of your supply chain. Take a look at our website where we go into the details on each type of test available, from a visual inspection to a key function test; we can do it all. We have many years of experience in testing for faulty or counterfeit products and components. We have a couple of articles on our website regarding this topic and its impact. If you have any questions about this service or anything else then please get in touch.

Visual Inspection

If you have any concerns over the authenticity of devices you are in receipt of, then use our visual inspection service to set your mind at ease. Working to DEA-STD-1010-B and MIL-STD-883G visual inspection standards as well as product data sheets, we will first inspect its packing condition to ensure it has been packaged and labelled correctly, then we will conduct a thorough inspection of the device’s markings such as date codes, country of origin, logo, tool/sand markings as well as identifying blacktopping, any contamination, lead defects and construction defects. Our inspection will also identify if the device is used or unused as it is against the law to sell a refurbished as new.

IC Repair

If you have integrated circuits in need of repair then contact Retronix Ltd to discuss the range of repair and refurbishment services we have available. Our technical team are qualified to undertake repair and restore tasks such as leg straightening on ICs for auto placement purposes and replacing or refurbishing alloys on IC legs to resolve solderability issues or for conversion to/from lead alloy and lead-free alloys. We are also able to provide a verification testing service to assess mechanical and electrical compliance and to verify and confirm correct alloys for component leads.

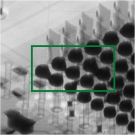

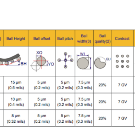

BGA Reballing

BGA Reballing is a refurbishment process used place new solder spheres on components. There are several different reballing methods but Retronix employs laser reballing, which is an innovative approach that is less damaging to the IC through minimised heat transfer and individual reflow of each sphere. All BGA reballing is undertaken in a cleanroom environment in a nitrogen atmosphere. Please contact us to find out more about our unique BGA reballing process and to discuss your individual requirements.

Contract Labour

Retronix Contract Labour service provides the perfect manpower solution for filling short-term and long-term labour shortages with personnel skilled in PCB repair work, including production operators, test/inspection operators, SMT/PTH solderers, SMT repairers, technicians, engineers and PCB debug technicians. Whether you are looking for extra staff to meet increased workloads or cover holidays or you need to fill a particular skills gap within your team, you can rest assured knowing that you will only be supplied with high quality staff that have undergone tests and checks and have also had references verified. Contact us today to find out more.

New Product Introduction

Building prototypes for new products can be a costly exercise with several tweaks and amends being necessary in the process of manufacturing the perfect product. In particular the cost of new ICs for each different prototype can become very expensive. Retronix offers a unique IC Rescue process which enables you to reuse ICs. The process involves the safe removal of the IC, the removal of excess solder from the BGAs, laser reballing, automated cleaning and finally mechanical and electrical testing of the IC to ensure it is working fine.

XRF Testing/XRF Analysis Facility

Retronix’ XRF testing and analysis facility was introduced to accurately identify the specific alloy that has been used on a particular termination, and thus determine if it is leaded or lead free. We are able to conduct XRF testing on any device including capacitors, connectors, resistors, BGSs, TSOPs and QFPs and you will receive a certificate for each device that confirms which alloy has been used. On receiving the results customers can then decide if they would like Retronix to convert the alloy in question or to refresh it if required.

Solderability Testing

Our testing capabilities covers solderability testing which is undertaken to JEDEC standards and allows us to confirm if a component is ‘re-solderable’ in advance, therefore avoiding potential solderability issues during the manufacturing process. Please also contact us to discuss our 3rd party arbitration service, which has been established in order to redress any supplier issues or disputes.

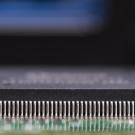

Electrical IC Testing

Retronix’ electrical IC testing process is used to detect possible defects of the electrical parameters of a component that may be as a result of heat damage, electrical overstress or electrostatic discharge (ESD) damage. It can also be used as a identify counterfeit components. It is also an important step in our unique IC Recovery process. We have the capabilities to conduct both powered and unpowered electrical testing and have invested in the area of Curved Traceability for powered testing.

Key Functional Testing

Key Functional Testing (KFT) serves to establish the working condition of a component and is conducted by our engineers, who use a test circuit and datasheets to analyse the device in question. During the assessment process a variety of tests are carried out which check the devices performance. Our engineers are also able to carry out KFTs on a number of other components, including passives and we also apply this testing process as part of our IC Recovery service to verify the working order of the component.

Flash Memory Testing

With so many counterfeit components on the market we have a team of programmers at the ready for verification of your programmable components to identify counterfeit items. Our flash memory test is a simply and highly effective process that covers a comprehensive list of programmable supported parts including FLASH, NAND and programmable PICs as well as supported SRAM parts. Please contact us to discuss your requirements and for further details of our Flash Memory Testing service.

Decapsulation

Retronix utilise the automated etching process for safe decapsulation of plastic moulded packages, which enables investigation to be undertaken at die level. Decapsulation is another way that Retronix can determine the authenticity of ICs and we also use it alongside high magnification analysis to establish the presence of any damage on the exterior of the IC that could be a result of repacking and reassembly.

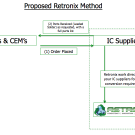

OEM/CEM PCB Assembler

Our IC recovery, refurbishment and testing services can benefit many OEMs and CEM PCB Assemblers in a number of different ways. Firstly, production costs can be reduced by reusing ICs which is made possible by our IC Rescue service, allowing possible savings of up to 80% of a PCBs value. Secondly, it allows you to reuse scarce components. Thirdly, it removes any concerns regarding the authenticity of ICs as by reusing your own you know where they are from. Lastly, it is a fantastic ways of lessening your company’s impact on the environment through recycling components.

Defence, Medical & Aerospace

Organisations in the defence, medical and aerospace industries trust Retronix to deliver highly reliable solutions that they can trust. In these sectors many original manufacturers of electronic components do not support or replace older components which are essential to the operation of their systems, the reliable function of which is critical. We work with these industries to provide analysis of components they have sourced from independent distributors to establish defects, counterfeits and faulty items. We also source items on their behalf, which are then tested. Either way they know they are in receipt of functional, authentic items.

Electronic Service Repair Company

Save valuable time by letting Retronix source authentic ICs for you and make savings of up to 20% compared to new purchase prices. We enjoy the challenge of locating hard to find components and will only ever source authentic parts. We can also store them for you if required, at no extra cost. Our unique capabilities for IC Rescue, developed for the safe removal and refurbishment of ICs from faulty PCBs, can also save you money, so speak to Retronix today and find out how are services can help your business achieve cost savings.

IC Component Supplier

If you are an IC Broker you need to ensure the ICs you are selling are faultless, of a high standard and not counterfeit in order to retain integrity with your clients. It is becoming more and more difficult to establish the authenticity of ICs as counterfeiters become more sophisticated in the techniques they use. Retronix can assist by removing components directly from PCBs and then refurbishing them to the highest standards. By utilising our electronic component testing, IC recovery, BGA reballing and testing services you will ensure your customers are in receipt of authentic, functioning components.

Electronic Material Recycler

An alarming amount of PCBs are sent to scrap when they could be recycled and reused. Until recently this has not been possible but with the development of our IC Rescue service, we can now reduce the amount going to landfill, assist in the eradication of counterfeit device trading and at the same time help you to achieve increased revenue as after they have been recovered and refurbished we will sell them on and give you some of the profit. You will receive documentation and certification for each part and will be able to track its whereabouts through our global tracking inventory system.

Details

Info

| Registration Number: | SC131176 |

| VAT Number: | GB612 4527 67 |

| Registered at Companies House: | 12 April, 1991 (33 years ago) |

| No of Employees: | 251-500 |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Brand & Trade Names

- Retronix Component and PCB Recovery/Repair

- Retronix Certified Counterfeit Detection and Testing of Electronic Components

Company Certifications

| ISO 9001:2015 - Quality management systems – Requirements |

Products & Services

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Aluminium Rod Extruders, Extrusions

- Barcode Labels

- PORTAL COVENTRY LLP

- E W Recycling Ltd

- Water Industry

- L D Wyatt Ltd

- NETZSCH-Instruments

- Community Energy Scotland

- The Health Care Training Company Ltd

- Henry Uk Ltd

- Civic Insignia

- Cutlery

- Reprofit Ltd

- Squad51 Ltd

- H2 Only Ltd

- Ummul Mumineen Academy Cic

- DOGAN ACCOUNTANCY LTD

- Pump Sales Direct Ltd

- Companies beginning with P