- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Lee Spring Ltd

Overview

- Mr Christopher Petts - Managing Director

- FERMISCO, Susan - Director

- KEMPF, Stephen Robert - Director

- PETTS, Christopher John - Director

Products

Lee Spring is the UK supplier of choice for catalogued and custom springs, including compression springs, torsion springs, constant force springs, die springs, belleville spring washers, wave springs, extension springs, battery springs and numerous speciality springs. Materials include steel, stainless steel, cobalt/nickel alloy, bronze, brass, music wire and composite plastics.

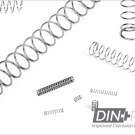

Compression Springs

We supply a wide selection of compression springs to suit different applications such as automotive engines, stamping presses, appliances, lawnmowers, cell phones, electronics and more. Compression springs are open-coil helical springs that are constructed to oppose compression along the axis of the wind. They offer resistance to linear compressing forces and one of the most efficient energy storage devices available on the market today. The straight metal coil spring is the most commonly used spring and features the same diameter for the entire length of the spring. Other configuration options are available for compression coil springs including hourglass (concave), conical and barrel (convex) types.

LeeP Plastic Composite Springs

LeeP Springs have been expertly designed and created to combine the strength of metal with the special attributes of high performing engineered thermoplastics. They are fabricated in distinctive formulations of Ultem PEI resins and are stocked in a range of sizes each with different strengths. These strengths are easily identifiable by the distinct colours of red, orange, yellow, green, blue and violet. Alongside our standard range of LeeP springs we are pleased to be able to manufacture LeeP compression springs to suit specific customer requirements. LeeP springs are used in a range of applications where non-corroding, non-metallic, inert materials are required.

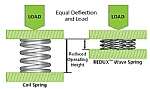

REDUX Wave Springs

REDUX wave springs have been designed and manufactured to provide optimum performance in reduced spatial environments. They have been expertly created to replace conventional round wire compression springs used in applications that require a tight load deflection specification in a space critical environment. REDUX wave springs occupy a very small area and can reduce the size and weight of assemblies by as much as 50% compared to the use of other alternatives. They feature a single filament of Type 17-7 stainless steel flat wire that is formed in continuous precise coils with uniform diameters and waves.

Die Spring

We are pleased to supply HEFTY™ Die Springs. These heavy-duty metal compression springs are manufactured using round wire and have been specifically designed for use in heavy stress or heavy load applications.

HEFTY™ die springs are cost effective alternatives to comparable, rectangular wire springs and demonstrate an equally long life expectancy. They are shot-peened for extended life, preset to prevent length loss in operations, powder coated and colour coded for ease of identification and feature closed or ground ends.

Five different configurations are available to suit medium to extra heavy duty applications.

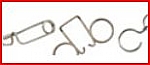

Torsion Springs

Torsion springs are used in a wide range of applications such as clothes pins, clipboards, swing-down tailgates and garage doors. They are helical springs that exert a torque or rotary force. They are designed and wound to be actuated rotationally and to provide an angular return force. The ends of the torsion springs are attached to components and as the components rotate around the centre of the spring, the spring tries to push them back to their original positions. Torsion springs are usually close wound but can feature pitch to reduce friction between the coils to suit specific application requirements.

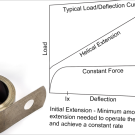

Extensions Springs

Extension springs are used for a range of applications such as automotive interiors and exteriors, garage door assemblies, vise-grip pliers, carburettors, trampolines, washing devices, farm machinery, toys and more. The ends of the springs are attached to other components. As the components move, the spring tries to bring the ends together. The initial tension determines how tightly together an extension spring is coiled. Our extension springs feature full diameter loops with openings of approximately one wire diameter and the direction of the wind is optional. They are available in inch or metric designs.

Belleville Springs

Belleville washers are manufactured from 300 Series Stainless Steel in order to offer excellent corrosion resistance when used in a wide range of applications. They feature a conical configuration which enables them to support high loads with relatively small deflections and solid heights compared to alternatives such as helical springs. Our top quality Belleville washers are widely used to solve various problems such as vibration, thermal expansion, relaxation and bolt creep. They are passivated in accordance with specification ASTM A967 to remove contaminants and improve corrosion resistance.

Custom Springs

Here at Lee Springs we provide a bespoke service whereby we design and manufacture springs to suit specific customer requirements. We provide customised solutions for our complete range of springs including: compression springs, LeeP plastic composite springs, REDUX wave springs, constant force springs, extension springs, torsion springs, wire forms, stampings and fourslide parts. To find out more about our services, please contact our friendly team at Lee Springs.

Manuals & Brochures

Details

Info

| Registration Number: | 01355982 |

| VAT Number: | n/a |

| Registered at Companies House: | 6 March, 1978 (46 years and 1 month ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Brand & Trade Names

- Bantam micro springs

- Hefty heavy duty compression springs

- LeeP plastic springs

- Lite Pressure

Company Certifications

| ISO 9001:2015 - Quality management systems – Requirements |

Products & Services

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Rtp Training Ltd

- Principle8 Ltd

- Jpr Electrical (Kent) Ltd

- GRP (Fibreglass) Marine Products

- Inert Gas Generators

- Postcodes beginning with S

- Waj Ltd

- Air Vents

- Architectural Models

- Akandeniz Ltd

- Ductwork Services (Iow) Ltd

- Selwood Homes Ltd

- IPS COUNTRYWIDE LTD

- High Shear Co-extrusions Extruders, Extrusions

- Apex Access Ltd

- Electronic Filters

- Boom Photography Ltd

- R&R Ice Cream UK Ltd

- Catering Environmental Ltd