- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Lee Products Ltd

Overview

Products

With over 70 years of experience, The Lee Company are world renowned for providing high quality, reliable engineering solutions. Specialising in fluid control products, we have invested time and money in creating innovative, problem-solving components. We are proud to have provided products to a wide range of industries, including automotive, scientific and industrial, just to name a few. Our components are being used all over the world, inside cars and aeroplanes, helping hospitals to diagnose diseases and even in the Lunar Module. One of the reasons why The Lee Company is trusted by so many is that we put our products through rigorous quality control, ensuring that our customers receive a solution that is not only effective but also reliable and safe. We also understand that every customer is different and some fluid control problems will be more complex than others. Fortunately, we can work with any industry and any business, large or small, to provide the ideal solution.

Customers can visit our website for much more information on the products and services that we have to offer, as well as some background on The Lee Company Itself. However, if you’d like to talk with someone directly, don’t hesitate to get in touch with our amazing customer service team.

High Pressure, High Temperature Axial Piston Pumps - Visit our website

Lee's high pressure, high temperature (HPHT) axial piston pumps have been designed and manufactured with specific considerations in mind. The pumps feature a unique design that makes them ideal for use in the harsh conditions found in downhole tool applications. They also benefit from an increased resistance to contamination, thanks to the axial piston design. Furthermore, as the name suggests, the HPHT range can generate up to 10,000 psi and can operate in temperatures up to 400°F. It's worth noting that we also offer customised pump solutions, allowing for changes to the mounting configuration and inlet and outlet connections.

Precision Microhydraulics - Visit our website

Lee Products Ltd paved the way with the design, manufacture and supply of precision microhydraulics and was the only authority supplying the industry for more than 50 years.

We can achieve components from less than 0.01 in up to 1.0 in diameter and from 0.1 to 28grammes as well as size and weight reduction using operating pressures to 8,000 psi. Our 100% inspection and testing services enable us to provide products of the highest quality and the highest reliability. We provide innovative solutions for all kind of industry applications.

Please contact use for further information.

Lee Shuttle Valves - Visit our website

The Lee Shuttle Valve is supplied in four configurations and is designed to isolate the normal from the emergency hydraulic system during normal operation.

Configurations include: a spring based shuttle valve with the emergency port normally closed, the detented shuttle valve which features a poppet latch to close off either the emergency port or the normal port, selective shuttle valves with a non-biased, loose ball design, and inverse shuttle valves where the lower pressure inlet port is open to the common port instead of the higher pressure inlet port.

Lee Shuttle Valves feature miniature insert fits in the head of the actuator, non-interflow design, and low leakage or zero leakage.

Lee Safety Screens - Visit our website

We supply etched safety screens and machined and drilled safety screens. Our etched safety screens are manufactured from stainless steel to be tough and long-lasting and are of a simple design. They are suitable for hole sizes from .004inches to .020inches. Our machined and drilled safety screens are suitable for low Lohm, and high flow capability applications. They feature no burst or collapse at 7500 psid fully clogged, hole sizes from .002inches to .020inches and can be machined and drilled from solid stainless steel bar. We supply more than 150 standard versions to suit all kinds of industry requirements.

Lee Pressure Relief Valves - Visit our website

Our Lee Pri valves are supplied in two ranges – for pressure relief and sequencing or for thermal relief. Our Lee Pri valves for pressure relief and sequencing feature high capacity miniature inserts and are available in cracking pressures from 20 – 5400 psid.

Various models are available for low or high flow rate applications. Our Lee Pri valves for thermal relief are optimised for relieving small flows and feature low leakage and no elastomer characteristics. Our Lee Pri valves for thermal relief are available for 3000, 4000, and 5000 psi systems.

Please visit our website for detailed technical information or contact us at Lee Products Ltd for further information.

Lee Directional Flow Control - Visit our website

We provide various components for directional flow control. These include Lee Restrictor Checks, Lee Flow Control, and Lee Floserts. Lee Resister Checks are for metered flow in one direction and no flow in the other. Poppet lifts are to wide open position with only 20 psid.

Our Lee Flow Control components are available in a range of four sizes, feature wide Lohm rate selection and high pressure models are available. Our Lee Floserts are for constant flow regardless of differential pressure and provide a wide range of control.

Please contact us for more information regarding our Lee Directional Flow Control options.

Lee Restrictors - Visit our website

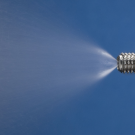

Our Lee Restrictors are widely used across the world for the manufacture of military and commercial aircraft. We offer restrictors to suit all kinds of applications. provide a wide range of single-stage orifices such as Lee Jets for higher Lohm rates, and Lee High Watt and Kilowatt Jets for low Lohm rates.

We also provide a range of multi-orifice restrictors which are either Bender Jets or Visco Jets. Our restrictors feature integral safety screens, reduce contamination problems, prevent cavitation, reduce erosion and are available in a range of body sizes.

Please visit our website and follow steps to work out which restrictor is most suitable for your application, or please contact us at Lee Products Ltd for help and advice.

Lee Plugs - Visit our website

Our Lee Plugs are manufactured for effective use for seal drilled holes in critical applications. To give you an idea of the scale of usage, more than 100 million Lee Plugs are currently being used in aircraft, missiles, spacecraft, machine tools, down-hole tools, molds, and many more applications. Lee Plugs feature proof pressures up to 32,000psid and can be easily removed. We also supply Lee Plug R.F.O. (Radial Force Only) that feature no downward pressure during installation and are ideal for thin wall applications, as well as Lee Plug A.F.O. (Axial Force Only) that seal to 56,000 psi, are reusable and are fore axial force only.

Please contact us or visit our website for further information on our range of Lee Plugs.

Lee Checks - Visit our website

We provide Lee Checks in a range of sizes and as forward or reverse flow, side exit, zero leak, or pilot operated versions and are supplied in three basic configurations. We supply Lo-LOHM Checks (poppet-style, high flow-gain check valves that are wide open at 15 psid and offer the lowest Lohm rate), Hi-Q Checks (offer the greatest feasible flow capacity for valve cartridges between ½ and 1inch in diameter), High Pressure Checks (poppet-style valves for up to 8000 psi systems),and Pilot Operated Checks (an all metal pressure piloted to open check valve).

Lee Piloting Solenoid Valve - Visit our website

The ultra compact Lee Piloting Solenoid Valve was designed and manufactured for use in aerospace hydraulic and fuel systems, oil tool applications, and other related high pressure applications.

The valve features high performance properties (efficient force/stroke relationship), low power consumption, normally closed and normally open valves for 3000, 4000, and 5000 psi, single

coil and dual coil configurations, multiple lead wire egress options, and integral connectors.

Please visit our website for further technical information.

Special Products - Visit our website

Alongside our extensive catalogue of mini and micro flow components we are also able to design and manufacture an equally comprehensive array of bespoke solutions. We understand that our customers’ applications are unique and as such approximately half of the the products we deliver are either adaptations of our standard products, for example tweaking certain elements of the product such as cracking pressure or leakage, or completely bespoke components that have been designed to meet our customers’ exact specifications. Please contact us so we can discuss your requirements in detail.

Electro-Fluidic Systems - Visit our website

We are proud to have created many pioneering components during the years that have proved essential for use in many industries. In the 1960s we created the Lee Interface Fluidic (LIF) solenoid valves to meet high performance and reliability demands of the industry. Since the development and success of this first electro-fluidic system, we have designed and created a range of fluid components that are suitable for complete systems for flowing all kinds of fluids and gases.

Please contact us for advice and information on how to build complete fluid handling systems using our highly accurate and reliable components.

Solenoid Control Valves - High Density - Visit our website

Our range of solenoid control valves includes both 2 and 3-port varieties, suitable for the control of air, gases and mild liquids. The valves themselves are compact, efficient and designed with low power consumption in mind. Featuring a small but effective build, these valves offer the ideal solution for applications where space is limited. Customers can choose from different series, including LGV, LHD, LHL and LHQ, with options to suit everyone.

Dispensing Valves - Visit our website

Our dispensing valves have been designed to control the flow of small amounts fluid at high-speeds. Lee Products’ VHS series of dispensing valves are popular for medical and scientific applications where the dispensing of fluid in microliters and nanoliters is required. Designed to deliver enduring performance, these solenoid valves can be adapted to meet the demands of your unique application.

Our INK series of solenoid valves delivers high performance and high speed ink dispensing for large character printing applications. These drop-on-demand dispensing and low power consumption valves are available with customisable options to suit your individual application.

Isolation Valves Control Valves - High Density Interface (HDI) Platform - Visit our website

Lee Products offers a comprehensive portfolio of HDI platform control valves that are designed to be utilised in applications that require controlled movement of air, gas or mild liquids. We have three solenoid valve designs to choose from:

- LHD Series - their compact size makes them ideally suited for use on a manifold. Available in 2-port or 3-port configurations

- LHL Series - magnetically latched with low power and low heat dissipation lending them well to portable applications

- LHQ Series - whisper technology design reduces noise transference by 50% therefore making them ideal for use in certain medical instrumentation where noise may pose a problem.

For each design you can also select from plug-in or face mounting styles, with 3-port designs also offering the option of ported mounting.

Fixed Volume Dispense Pumps - Visit our website

Our fixed volume dispense pumps are positive displacement pumps, which are solenoid driven. They benefit from a compact, lightweight design and can dispense volumes with great accuracy and repeatability. Fixed volume dispense pumps are normally utilised within the medical industry and therefore safety and reliability is key. Fortunately, we thoroughly test all our pumps prior to making them available to buy. We also utilise durable, chemically inert materials, ensuring our products are long-lasting and resistant to damage.

Variable Volume Dispense Pumps - Visit our website

We offer a variety of variable volume dispense pumps which utilise stepper motor technology in order to achieve positive displacement. The pumps themselves benefit from a compact, lightweight, maintenance-free design, ensuring they can be positioned anywhere they may be needed. All of our variable volume dispense pumps are offered as standard or high performance, with models to suit every need. Customers can be assured that this range offers exceptional accuracy, reliability and performance.

Manifold Technology - Visit our website

We began working in the field of electromechanical valve and pump technology more than three decades ago, swiftly becoming an industry leader. We have a wealth of experience with manifold technology which has several distinct advantages when compared to systems where discrete components are connected with just tubing. The number of leakage points is reduced and lower internal volumes are achieved. Manifolds offer a higher level of flexibility and are more easily assembled into the instrument. There are several different manufacturing techniques involved, including conventional, multi-layered, ant farm, combination and injection manifold. Our expertise in fluidics means we have a thorough knowledge of all the different techniques and understand both the components used, as well as the application they are to be used in. There is a good deal more information about manifold technology on our website, so do have a look.

Static Mixers - Visit our website

Our Visco-Jet micro mixer utilises cutting edge aerospace technology, allowing for effective and efficient static mixing. Thanks to an innovative design, the components utilise the liquids themselves in order facilitate the mixing and therefore do not require any external mechanical or electrical input. The liquids are mixed using 36 controlled spin chambers, ensuring effective and reliable results. Customers can visit the website for further information on this or any of our product ranges.

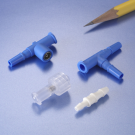

MINSTAC Tubing End Connections - Visit our website

MINSTAC stands for Miniature Inert System of Tubing and Components and it has been designed for use in conjunction with aggressive fluids. Lee Products has created a tube end solution that avoids the potential damage caused by these fluids at vulnerable connection points. This is accomplished with our specially designed Collet-Lock system, which creates a leak-proof connection between PTFE tubing and our MINSTAC components. We offer various standard tubing assemblies as well as fitting assembly tool kits.

Manuals & Brochures

Details

Info

| Registration Number: | FC008627 |

| VAT Number: | GB228 2148 74 |

| Registered at Companies House: | 6 June, 1975 (48 years and 10 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | 10-20m |

| Parent Company: | The Lee Company |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 08:30 AM - 05:00 PM |

| Tuesday | 08:30 AM - 05:00 PM |

| Wednesday | 08:30 AM - 05:00 PM |

| Thursday | 08:30 AM - 05:00 PM |

| Friday | 08:30 AM - 05:00 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Brand & Trade Names

- Discpump Piezoelectric miniature disc pump

- Lee Chek

- Lee Flosert Pressure compensated flow control

- Lee Hi-Bar Screens Machined-from-solid laser drilled screens

- Lee Jet

- Lee Plug

- Lee Pri Pressure relief valve

- Lee Viscojet Multi-orifice restrictor

Company Certifications

| ISO 9001:2015 - Quality management systems – Requirements |

Products & Services

- Acrylic Manifolds

- Acrylic Manifolds

- Biotech Pumps

- Check Valves

- Check Valves

- Control Valves

- Diaphragm Pumps

- Diaphragm Pumps

- Dispensing Pumps

- Dispensing Pumps

- Dispensing Valves

- Displacement Pumps

- Displacement Pumps

- Expansion plugs

- Flow Control

- Flow Control Valves

- Flow Control Valves

- Fluid Control Components

- Fluid Control Systems

- Fluid Dispensers

- HDI Platform Control Valves

- High Density Interface Solenoid Valve

- Hydraulic Components

- Hydraulic Components

- Hydraulic Filters

- Hydraulic Filters

- Hydraulic Non-return Valves

- Hydraulic Oil Filters

- Hydraulic Oil Filters

- Hydraulic Pressure Relief Valves

- Hydraulic Pressure Valves

- Hydraulic Valves

- Hydraulic Valves

- Ink Dispensing Valves

- Isolation Valves

- Medical Manifolds

- Medical Manifolds

- Metal Blanking

- Metal Blanking Plugs

- Micro-hydraulic Components

- Micro-hydraulic Components

- Micro-hydraulic Filters

- Micro-hydraulic Filters

- Micro-hydraulic Valves

- Micro-hydraulic Valves

- Miniature Filters

- Miniature Filters

- Miniature Solenoid Valves

- MINSTAC Tubing End Connections

- Non-return Hydraulic Valves

- Non-return Valves

- Non-return Valves

- Nozzles

- Nozzles

- Oil Pumps

- Pharmaceutical Pumps

- Piezoelectric Actuators

- Piezoelectric Valves

- Piezoelectric Valves

- Pilot Operated Valves

- Pilot Operated Valves

- Pinch Valves

- Pinch Valves

- Pneumatic Valves

- Pneumatic Valves

- Precision Flow Restrictors

- Pressure Control Valves

- Pressure Hydraulic Valves

- Pressure Reducing Valves

- Pressure Reducing Valves

- Pressure Relief Hydraulic Valves

- Pressure Relief Valves

- Pressure Relief Valves

- PTFE (Polytetrafluoroethylene) Tubes

- Ptfe Tubes

- Pvc Tubes

- PVC Tubes (Polyvinyl Chloride)

- Relief Valves

- Shuttle Valves

- Shuttle Valves

- Solenoid Hydraulic Directional Valves

- Solenoid Miniature Valves

- Solenoid Pneumatic Valves

- Solenoid Teflon Coating

- Solenoid Teflon Valves

- Solenoid Valves

- Solenoid Valves

- Stainless Steel Check Valves

- Stainless Steel Check Valves

- Static Mixers

- Static Mixers

- Static-in-line Mixers

- Static-in-Line Mixers

- Three-way Control Valves

- Valve Control Systems

- Venturi Jet Pumps

Gallery

Financial Information

To view more detailed financial information for this company click here.

Accepted Payments:

- ELITE GROUP INTERNATIONAL LTD

- NDT (Non-destructive Testing) Test Equipment

- Fairprice Stores Ltd

- Sports Facilities Builders

- Jumby Investments Ltd

- Vertical In-line Pumps

- Familiar Ltd

- ASI OUTSOURCING LTD

- Russ James Design Ltd

- Armco Property Management Ltd

- SIMON HUDSON CONSULTING Ltd

- Contractor Li Ltd

- Howarth Timber Group Ltd

- Lobo & Moras Ltd

- CARDIFF

- Westhill Estates (Leicester) Ltd

- Electroplating

- PVDF Tubes

- Roller Banners