- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Pfaudler Ltd

Overview

Products

For nearly 150 years, Pfaudler UK Ltd has been at the forefront of the process engineering industry by developing, manufacturing and installing an outstanding and diverse range of process solutions for chemical, pharmaceutical and other process industries across the globe. We are leaders in the industry, not followers, and invest in research and development to ensure that Pfaudler defines the standard. Delivering bespoke solutions to our customers that consistently meet and exceed their expectations whilst representing excellent value is what we aim to deliver.

Our solutions include:

- Complete chemical process systems

- Large, medium and pilot scale reactors and accessories

- Fluoropolymer linings and coatings

- Glass linings

- Filtration technologies

- Nutsche filter dryers

- Mixing technologies

We are a global manufacturer with seven sites over four continents and are divided into three brands: Pfaudler, Edlon and Tycon. Our support network is global too and with service delivery being a high priority we boast the largest team of field support experts in the industry.

If you would like to talk to us in detail about your individual process solution requirements then please do not hesitate to contact us.

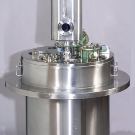

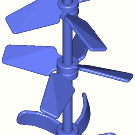

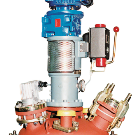

Reaction Technologies

We are proud to say that our reaction technologies are known and respected throughout the entire chemical industry. This is for a variety of different reasons, including effective design, reliability and safety. Just some of the processes which can be facilitated utilising our reactor technology includes, the safe containment of corrosive materials, maintenance of vessel pressure and ensuring high quality product. If you have any questions about this or any of our services, don't hesitate to get in touch.

Evaporation / Mass Transfer Technology

Our evaporation technology incorporates every aspect of the mass transfer process, including stripping, rectification, absorption and batch distillation. We can utilise this technology in a wide range of applications, including tall oil fractionation, high vacuum distillation, solvent recovery, fatty acid purification and pharmaceutical batch distillations, just to name a few. If you'd like to find out more about this process, don't hesitate to visit the website, alternatively you can contact us directly.

Heat transfer technology

Heat transfer is a factor which affects everything from quality and repeatability, to operating times and costing. It's for this reason that we strive for maximum heat transfer. This is achievable thanks to the effective design of reactor internal geometries, mixing systems and jackets. It's also worth noting that our heat exchangers are designed and manufactured with reactivity in mind and utilise metals such as niobium, zirconium and tantalum. If you any questions about this technology, feel free to give us a call.

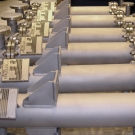

Filtration Technology

Filtration is a key process within many different industries, particularly pharmaceuticals and agriculture. Our filtration technology has been designed for maximum yields with an emphasis on quality, efficiency and safety. Whether the product is the liquid or the solid component, our filters offer exceptional performance. We utilise an array of different filters, including stainless steel, Glasteel® and fluoropolymer lined constructions. Further information can be found on our website.

Drying Technology

Our drying technology includes solutions for a variety of different applications. For example, we use stainless steel dryers in the processing of pharmaceutical compounds, stainless steel / Glasteel® double cone dryers and Glasteel® evaporator dishes for corrosive materials. It's worth noting that we can provide complete drying packages which include vacuum drying, solvent recovery and product charging/discharging. If you'd like to find out more about these services, please visit the website.

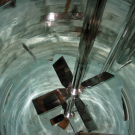

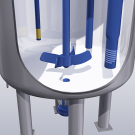

Mixing Technology

Within a batch reactor the mixing process is vital to factors such as quality, cost effectiveness and efficiency. Through many years of research and hard work, we have created mixing technologies that are not only effective but also reliable, efficient, cost effective and tailored to real world applications. If you would like to find out more about our mixing technology, or any of our products and services, don't hesitate to visit the website. Alternatively you can contact our customer service team directly.

Corrosion Resistance Technology

Corrosion resistance technologies are integral within many different industries, particularly the chemical and agricultural sectors. Whether it's the production, storage or transportation of hazardous materials, safety is paramount. We can offer a range of effective, high quality and reliable corrosion resistance solutions, including fluoropolymer, Glasteel ®, reactive metal constructions, material transfer systems, filtration systems, drying systems and instrumentation, as well as many more. Further details, including technical information can be found on the website.

Fluoropolymer Technologies

Our knowledge and experience with fluoropolymer technologies allow us to offer effective, reliable and tailored solutions for applications such as corrosive resistance, release performance and purity. It's worth noting that we can offer completely bespoke, vacuum formed fluoropolymer components which have been manufactured with specific requirements in mind. Just some of the different applications in which our technologies can be utilised include, oil-refinery, precious metal recovery, semiconductor chemistry, acid recovery and agricultural chemistry.

Ultrapure Technologies

Our range of ultrapure products and technologies are utilised in the processing of chemicals. For example they are often used in applications such as the removal of trace metal ions, silicate and particulate contamination. Our clean processing techniques ensure that cleanliness is achieved from the very beginning, guarding against cross-contamination and ensuring an ultrapure process. Further information can be found on our website, including technical details.

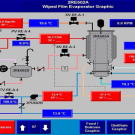

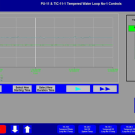

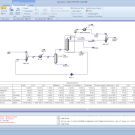

Controls Technologies

We can provide control systems for any application. These systems offer an alternative to manual operation, with a tighter degree of control over issues such as security, safety, data collection and reporting. We pride ourselves in offering control systems which are not only highly effective and efficient but also protective of the wider environment, property and workers. Further information can be found on the website. Alternatively, you can contact our customer service team directly.

Modular Design / Construction

We can provide completely modular process systems which can be utilised for many different applications, however large or small. Just some examples of such applications include, reactor systems, evaporator systems, vacuum systems, drying systems and distillation systems. There are many benefits to installing one of our modular systems, including improved quality, lower project costs and shorter construction schedules. If you have any queries about this or any of our services, feel free to give us a call.

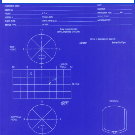

Storage Tanks and Receivers

Whilst the emphasis is often placed on the processing of corrosive and ultra-pure chemicals, storage is just as important. We can provide a wide range of storage equipment, including both Glasteel© and fluoropolymer-lined vessels. As well as offering standard products, customers are reminded that we can also provide completely bespoke storage tank solutions- if required. If you'd like to see everything we have to offer, including our storage tanks, please visit the website.

API Pharmaceuticals

We have many years of experience working with the pharmaceutical industry. This industry works with a lot of different chemicals and therefore require technologies which account for corrosion and clean-ability. We can provide complete solutions to customers working within this sector, including clean reactor design, optimised jacket design, Pharmaglass (PPG®) and anti-static glass (ASG®). If you would like to find out more about our pharmaceutical products and services, feel free to visit the website.

Nutraceuticals

The nutraceutical industry works with materials that are particularly sensitive to heat. It's for this reason that specialised purification systems are required. We can provide Wiped Film Evaporator (WFE) technology which is effective in the distillation of a range of nutrients, including vitamin C, omega 3 fatty acids and vitamin E tocopherols, as well many more. It's worth noting that we can also provide complete nutraceutical evaporation systems which incorporates all aspects of the process, including distillation, de-gassing and vacuum.

Bio-Pharmaceuticals Solutions

When it comes to Bio-Pharmaceuticals, our Glasteel© reactor offers the perfect solution. Just some of the benefits to utilising our Glasteel© technology includes clean-ability, trace-ability, greater efficiency, durability and reduced maintenance. These benefits do not only increase productivity and quality but also help in the reduction of costs. If you would like to find more about our Bio-Pharmaceutical solutions, don't hesitate to visit the website. Alternatively you can contact our customer service team directly.

Agricultural chemicals

The agricultural industry works with a wide range of chemicals, many of which are corrosive or harmful. This sector is constantly striving to create better and more effective products and this means processes can become quite intense, requiring durable and reliable equipment. We can provide tailored solutions for the processing of agricultural chemicals, including our Glasteel© material, a variety of process mixing options, aftermarket support and field service support. To find out more, please feel free to visit the website.

Semiconductor Chemistry

Within semiconductor chemistry purity is extremely important to every process, whether it's production, storage or transportation. We can achieve this through the use of Edlon's fluoropolymer materials which are known for their chemical inertness and low ion particle shedding. Edlon can offer complete solutions for the semiconductor sector, including the design of columns, tanks, containers and vessels. If you'd like to find out more about this service, please don't hesitate to visit the website.

Fluorine and Chlorine Based Chemistry

The processing of hydrogen fluoride (HF) and hydrochloric acid (HCL) can be quite difficult for a variety of reasons. These particular chemicals are highly corrosive and therefore difficult and dangerous to work with. Edlon's fluoropolymer technologies offer an effective and reliable solution to these problems. These technologies allow for the safe containment and processing of highly concentrate HF and HCL. If you'd like to find out more about this service, or you have any specific queries you can contact us by phone or email.

Acid Recovery

Acid recovery, specifically the recovery of sulfuric and nitric acids is a practice which is not only environmentally friendly but also cost effective. The actual acid recovery process requires specialised equipment. Many of our technologies are ideal for this application, including Glasteel© materials, fluoropolymer materials and our range of exchangers which include zirconium, tantalum and silicon varieties. As concentrated acids are involved, safety is just as important and this is also factored into our solutions.

Polymers

The processing of polymers requires equipment that has exceptional non-stick properties. Our Glasteel© technology is the ideal solution for polymerizers as the glass finish is both non-stick and easy to clean. This non-stick coating is incredibly important during the heating process as it stops the product adhering to the heating wall and becoming burnt. It's also worth noting that we can offer upgrades and enhancements for polymer technologies, everything from level instrumentation and temperature measurement to heating and cooling jackets.

Fine / Specialty Chemicals

Every manufacturer is different and requires solutions that meet their specific needs. For example, fine and speciality chemical manufacturers produce lots of different types of products but in smaller batches. This type of fast turnover requires reactors that are not just effective but also specialised. Our Glasteel© technologies can meet these demands as they are anti-corrosive, non-stick and easy to clean, ensuring less downtime in between batches. We also offer a range of different mixing technologies which include those required for low batch volumes.

Water Treatment Chemicals

Water Treatment includes a variety of different processes, including the production of Polyaluminum chloride (PAC) - a coagulant use when treating potable water. When producing PAC, the reaction process can be extremely corrosive and therefore glass lines reactors are utilised. Our reactor PAC technologies include corrosion resistance, abrasion resistance, high pressure jackets and process analytical instruments. If you'd like to find out more about these or any of our products and services, please visit the website.

Oil re-refining

We have the experience and the products to work with the renewable fuel industry with processes such as oil re-refining. Our technology, specifically our Wiped Film Evaporator (WFE) technology can be used in the distillation of used oil in order to produce a lube distillate. Our WFE systems also facilitate the removal of light ends and heavy contaminants. If you'd like more information, including technical details, you can visit the website. Alternatively you can contact our customer service team directly by phone or email.

Biodiesel

We understand the importance of supporting renewable fuels. Our Wiped Film Evaporator (WFE) technology can be used in the processing of crude biodiesel in order to create water white biodiesel. It's worth noting that we also offer a complete biodiesel system which includes distillation, de-gassing and vacuum technologies. If you have any specific queries feel free to get in touch with our customer service team, by phone or email.

Details

Info

| Registration Number: | 02197267 |

| VAT Number: | n/a |

| Registered at Companies House: | 20 November, 1987 (36 years and 5 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Gallery

Financial Information

To view more detailed financial information for this company click here.

- All I Can Ltd

- Ce2 Ltd

- San Contracting Ltd

- Equipment Calibration Transducers

- Solder Fume Extraction Equipment

- Arrow International Production Ltd

- Plastic Tubes

- Victor Global Trade Co. Ltd

- Yorkshire Care Solutions Ltd

- Spray Gun Pressure Pots

- Top Building Control Ltd

- Homes Overseas 4 You Ltd

- Bath Flow P.C Harris Ltd

- LEICESTER

- Infinite Physique Ltd

- Gymnasium Equipment

- Changeworks Recycling

- Hm-ant Ltd

- Hotline.co.uk