- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

MPE Electronics

Overview

Products

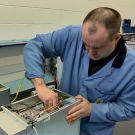

MPE Electronics is a leading contract electronics manufacturer with more than 30 years of industry experience. Operating from an 11,000 sq ft factory in Uckfield, East Sussex, we provide component solutions for all the major markets, including aerospace, medical, defence, telecommunications, security, instrumentation and temperature control. A collection of surface mount and through hole assembly systems allow us to produce customised PCBs to meet the requirements of just about any application.

We also have a full range of test and inspection equipment that helps guarantee component quality and reliability, both of which have become hallmarks of our service. Indeed, it’s our commitment to delivering products of the very highest standard that has seen MPE Electronics grow to become one of the industry’s leading suppliers.

As well as quality products, we offer competitive pricing and a fast, friendly and efficient service – a rare combination in any industry. Few other contract electronics manufacturers can match us for products, price and performance.

Neither can they keep up with our ability to meet the ever-changing needs of the electronics industry. Our policy is to constantly monitor advances in manufacturing methods, machinery and technology so that long-term investments can be made that enable us to be the versatile supplier that the modern market demands.

To find out more about MPE Electronics and the services we offer, visit us online or get in touch with our Sales Director on 01825 749954.

Pre-Manufacture

MPE Electronics offers a full prototyping service for Printed Circuit Board assemblies and can provide all the information you need on component pricing, availability and obsolescence. We work closely with our customers to advise and guide them on PCB layout for manufacturing and testing before releasing boards for production.

Component Procurement

A fully computerised stock management system means that ordering and updating of materials is kept under close control. Meanwhile, access to major worldwide distribution outlets means we can source just about any component needed to produce your customised PCBs.Find out more about component procurement at MPE Electronics by heading over to our website or calling us on 01825 764822.

Surface Mount Assembly

Our policy of continuous reinvestment has endowed us with a range of surface mount technologies that enable the fulfillment of even the most complex PCB orders. Our automatic placement equipment allows us to place BGA, FPGA, Micro BGA and discreet components to 0201 size. The manufacturing process includes automatic paste printing using DEK printer technology and lead-free soldering using BTU convection reflow systems. Find out more about our surface mount assembly services by visiting MPE Electronics online.

Through Hole Assembly

Depending on the batch size and board complexity, leaded components are pre-formed, manually inserted and either wave or hand soldered. All operators are trained to IPC610 workmanship standards, ensuring component quality, performance and reliability. For more information on our through-hole PCB assembly services, visit MPE Electronics online or get in touch on 01825 764822.

Inspection

To ensure that our components meet the standard required, we use a Mirtec Automatic Optical Inspection (AOI) system. Utilising state-of-the-art software, this machine has true character recognition and by a variety of lighting techniques is able to identify most solder defects. The Mirtec Automatic Optical Inspection system is programmed offline so that it does not interfere with daily production requirements.

BGAs and micro BGAs, meanwhile, are inspected using an Ersa Scope Optical System.

For manual inspection we use Mantis 2x – 10x viewers as well as an EV microscope with 10x – 50x magnification.

Test

Most of our customers require a fully tested board assembly. To meet this requirement we have a dedicated test department where Automatic Tests (ATE), comprehensive in-circuit tests using TRI Manufacturing Defect Analysis Systems (MDA) and semi-automatic jig tests are carried out. Environmental tests can also be performed using our Montford environmental chamber, which has a temperature range of -40°C to +125°C. For more information on our PCB testing services, please visit MPE Electronics online.

Plant

MPE Electronics is constantly upgrading and adding to its already considerable PCB production plant. Machines currently in operation include;

Kit Preparation / Materials Control:

- 1 x Elite Engineering Axial Component forming Machine

- 1 x Boss Z2000 Component vacuum sealing machine with nitrogen

Surface Mount PCB Assembly:

- 3 x DEK 265 Infinity Automatic screen pasting machines

- 1 x Tetra 23” Stainless steel foil loading system

- 2 x Mydata MY15 Pick and Place machines with full optical alignment and component verification system

- 1 x Mydata MY19 Pick and Place machine with full optical alignment and component verification system

- 1 x Circuitmaster profiler

- 1 x BTU International Paragon 98 7-zone convection reflow oven

- 1 x BTU VIP 98 7-zone convection reflow oven

- 1 x BTU International Pyramax 98 7-zone convection reflow oven

- 1 x SLC500 Vapour Phase Oven

Through Hole PCB Assembly:

- 1 x Blundell CMS400LF Flow soldering machine (Lead Free)

- 1 x Weller Hot Plate WHP3000

- 20 x Weller High Temperature Soldering Irons

- 2 x FKN SYSTEK PCB Depaneling machines

Inspection / Quality Control

Inspection plant currently used by MPE Electronics engineers includes:

- 1 x Mirtec MV-2HTL Automatic Optical Inspection Machine

- 1 x Mirtec MVL-3 Automatic Optical Inspection Machine

- 1 x ErsaScope 1 with x 400 magnification

- 2 x Mantis Viewing stations with x2 and x4 magnification

- 4 x Mantis Viewing stations with x4 and x8 magnification

- 1 x Teknos ESD Continuity tester

- 2 x SRM-100/3 Surface resistance meters for benches and floor area

- 1 x Weller WCB2 Digital thermometer

- 1 x Brother P-Touch 2700 Serial label printer

Manuals & Brochures

Details

Info

| Registration Number: | 01994847 |

| VAT Number: | n/a |

| Registered at Companies House: | 3 March, 1986 (38 years and 2 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: |

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Products & Services

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Circular Brushes

- TAJ CALLANDER LTD

- HATM Ltd

- Alloy Turned Parts

- Facing Bricks

- Dodge Transport Ltd

- Posh Audio Ltd

- SAFFRON WALDEN

- Stainless Steel Exhaust Systems

- SURGICAL SPECIALTIES CORPORATION Ltd

- Pro-Tech CP Ltd

- Brain Lounge Ltd

- Synergie Business Solutions Ltd

- Eash Ltd

- Fencing

- The Worcestershire Imaging Centre Ltd

- Self Storage Containers

- 3d Networks (UK) Ltd

- Urban Education & Training Group Ltd