- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Farleygreene Ltd

Overview

- Mr Antony Hare - Managing Director

- HARE, Antony Robert - Director

Products

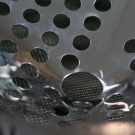

We have been producing and supplying screening and sieving equipment to the food, chemical, pharmaceutical and associated process sectors for more than 30 years.

Our range includes simple check sievers, grading separators, linear screeners, rotary sifters, gyratory feeders and screeners as well as laboratory sieves. We also offer an extensive range of spare parts and accessories including ultrasonic de-blinding that can improve throughput times by up to 300%.

Many of our products are made to specification, and we also design entirely bespoke systems that can incorporate machinery from one of more of our numerous partners, providing a cost-effective solution for virtually any application.

Sievmaster

The Sievmaster range of industrial sieves can be used with dry or wet materials. The equipment is ATEX approved and can be adapted to suit the requirements of almost any application.Available products in the Sievmaster range include:

- Sievmaster Slimline

- Sievmaster Easilift Station

- Sievmaster Segregator

- Sievmaster Vacusiev

- Sievmaster 200 - S

- Sievmaster 500 - S

- Sievmaster 700 - ST

- Sievmaster Multiscreen

- Sievmaster Rota

These include models to check screen and sieving of liquids or powders, segregators to dewater or dedust materials, dust-free conveyance and sieving, batch sieves, grading sieves, centrifugal grading sieves.

We also offer Vipower / BM & M gyratory and vibratory large screeners.

Magnetic Separators

Farleygreene are able to supply virtually any type of magnet you might require for a process line – from single magnet bars right through to geared rotating magnetic arrays within enclosed boxes. Because all of our products are made to order, we’re able to tailor your magnetic assembly according to your exact processing requirements.

All magnets are made from rare earth neodymium, a very stable material with a long magnetic life. They can be supplied in a number of strengths, but the most common are those with 7000, 9000, 11000 and 14000 gauss ratings. Every magnetic part will be enclosed within a stainless tube, plate or bar – these can be quickly fitted within our sieving machines.

Find out more by visiting the Farleygreene website.

Linear Screeners

Many of our customers process materials that require de-dusting or de-watering. For these processes a flat rectangular screener is needed. These employ a gentle but powerful action to achieve an excellent liquid/dust-free product – without damaging it in any way. Even fragile products such as biscuits or fruit can be processed using a screener.

All of our screeners are made to order, meaning they can be customised in accordance with the requirements of your processing plant. Indeed, we can adapt these systems to virtually any situation, no matter how improbable it may seem. Visit our website to find out more.

Grading Separators

Grading separators are used to assign products into different sizes. In fact, for any single product up to five sizes can determined using mesh screens. Our grading separators include:

- Sievmaster Multiscreen Separator – This vibratory separator can grade products in one pass into 2 to 5 particle sizes. It is available in 800, 1000 and 1200mm diameters. Mesh sizes can easily be changed to suit product requirements.

- Sievmaster 700 – ST – A powerful, 565mm grading sieve based on a proven design but with many important upgrades.

- Vipower / BM & M Gyratory Screeners – Ideal for aggregates, woodchip, recycling, rubber crump, etc.

Many systems in the Sievmaster range can be used to perform this function, even though they are not primarily ‘grading sieves’. They include those in the Slimline Range, Rota Series, and the Vacu Siev.

Laboratory Sieves

Farleygreene design and manufacture a variety of shakers for use in laboratory applications which require particle sizing and separation to the tightest tolerances. They offer an incredible sieving action that provides consistently accurate results in an unbelievably fast operating time – therefore fulfilling all the key requirements of the laboratory. If you would like to find out more about how they work and they benefits they offer, please visit the Farleygreene website.

Vacuum Conveyors

Vacuum conveyors offer a non-electrical, non-mechanical and ATEX approved means of transporting hazardous and/or dusty products which could cause harm to operatives if they were exposed to them. They are suitable for any environment in processing industries, and when used in conjunction with our Sievmaster vacuum sieving units they provide the user total control over hazardous or dusty materials. You can find a brief description of how our vacuum conveyors work and the ways in which they have been implemented into existing facilities by visiting the Farleygreene website.

Bespoke Systems

We develop bespoke sieving, sifting, and separating

solutions for a wide range of applications. Whether it’s a minor adjustment to

our existing products, adding new accessories, or creating something new from

scratch, our team can build something that suits your individual requirements.

Our standard ranges are easily customised, with affordable extras that can be

easily installed and maintained, and we are happy to advise on the best

products to suit your needs. We can also ensure our products meet codes such as

EU directives on food safety, ATEX certifications, FDA approval, and many more.

Get in touch to find out how we can improve your screening and throughput

rates.

Ultrasonic Deblinding System

The use of ultrasonic frequencies can have many advantages

to using vibration technology, and can help the product slip through the mesh

more easily. This could accelerate your sieving process, and has helped some of

our clients achieve up to a 200% increase in their throughput rate, as well as

cutting down on mesh clogging and blocking. Working closely with Artech

Ultrasonic Systems AG, we can create custom-made ultrasonic screening systems,

and these create a unique solution for clients from all sorts of sectors.

Ultrasonic sieving works very well for very fine materials, where normal

sieving just isn’t practical, and we carry out tests to ensure the correct specification

for your products.

Vipower BM & M Screeners

Our gyratory screeners are often used in recycling,

aggregates, environmental, good, cleaning, and vegetable grading environments,

but have a wide range of applications that can be used. With gyratory screeners

available in sizes up to 4x6 metres, we have a wide range of extras including

volume feeders, vibratory conveyors, and high quality screens, which can be

customised to meet your exact product requirements. This allows for high

quality screening at high volumes, and can be used for grading materials into

multiple grades, for accurate motion of materials, and through screen openings

or layers.

Manuals & Brochures

Details

Info

| Registration Number: | 01243329 |

| VAT Number: | GB302 1122 42 |

| Registered at Companies House: | 6 February, 1976 (48 years and 2 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:00 PM |

| Tuesday | 09:00 AM - 05:00 PM |

| Wednesday | 09:00 AM - 05:00 PM |

| Thursday | 09:00 AM - 05:00 PM |

| Friday | 09:00 AM - 05:00 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Brand & Trade Names

- Sievmaster Powder and liquid sieveing equipment

Company Certifications

Gallery

Financial Information

To view more detailed financial information for this company click here.

- XTREME CUT BARBERS LTD

- Gripping Pads

- CITIZEN COSMETICS Ltd

- Self-adhesive Strip

- Walkway Grating Flooring

- The Smart Restaurant Ltd

- Yorkshire Payroll Bureau Ltd

- Fridge Door Seals Ltd

- Complete Workspace Solutions Ltd

- SWANSEA

- Menu Cases

- ESSEX LANDSCAPING & GROUND MAINTENANCE LTD

- Assura Todmorden Ltd

- Generator Installation, Maintenance, Repair

- Control Induction

- Mapleton Growers Ltd

- CSP RECRUITMENT 45 Ltd

- S.L.Conyers & Son Ltd

- Whaleslide Ltd