- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Engineered Air Treatment Ltd

Overview

- Mr Chris Hornsby - Sales & Marketing Director

- BISHOP, Adam - Director

- HORNSBY, Christopher - Director

Products

Engineered Air Treatment (EAT) has been supplying dampers and louvres for the noise-control and power generation industries for nearly 30 years. Our products have been installed on projects right across the globe, both on and offshore, and for a wide variety of companies operating across many different sectors. EAT dampers and louvres have been used in oil rigs and turbines, telecommunications, generator enclosures, general manufacturing, shipping, F1 racing and much, much more.

Our services are constantly expanding to meet the needs of our customers; we recently combined with our separate manufacturing company in order to provide clients with a complete design, sales, manufacturing and after-sales service. All of our dampers are now designed and engineered in-house, and can be adapted according to the client’s specific needs. And, as well as dampers and louvres, we can now offer sheet metal ductwork, grilles and diffusers.

Established in 1983, EAT is one of the most experienced suppliers in the market. We focus on delivering quality products and providing an outstanding service: a quality management system accredited to ISO 9001:2008 ensures our standards never slip.

Some of our products can be found listed in the sections below. To discover the entire range, please head over to our website, and if you would like any further information about our products and services, please do not hesitate to call. We’re available on 01162 600757.

Atex Dampers

Our ATEX dampers (CE EX II2G c IIC T1..6X) have been designed to cover Zones 1 and 2. They are similar to standard dampers, but are constructed mainly from stainless steel (304 or 316 grade) or aluminium. They feature 0.7mm double skin Z-type blades, bronze Oilite or nylon bushes, stainless steel spindles and spring-loaded side shims that minimise the gap between the casing and the blades. Each damper is custom-made according to client specifications – however, maximum width is 2000mm and maximum height is 3000mm. ATEX dampers can be supplied with a compliance report if required.

Blast Dampers

EAT’s blast dampers are certified to function up to 35kN per square metre. There are two options when it comes to designing a blast damper:

Option A – Blades are open and shut down on blast

Option B – Blades are closed and open on blast

The choice depends on the environment in which the damper is to be installed. Both types feature 2mm pre-galvanised mild steel or stainless steel casings, self flanged and undrilled flanges (as standard), bronze, Oilite bronze or SFL bush bearings, 16-20mm stainless steel spindles, and 2mm interlinked blades (designed to rise and fall in unison).

Find out more about our blast dampers by visiting Engineered Air Treatment online.

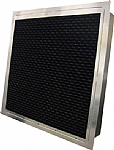

Filter Gates

Our filter gates are designed to hold various filter media. They are designed in flat formation or in V formation, with one side fixed and the other hinged for access. The filter gate’s housing can be made with pre-galvanised mild steel, aluminium, 304 or 316L stainless steel. Maximum height is 2500mm; maximum with is also 2500mm. Otherwise, filter gates can be made to virtually any size you require. For more details and specifications, please head over to our website or contact us directly on 01162 600757.

Fire Dampers

All of our fire dampers are fire endurance tested for 6 hours. This is certified by the Warrington Fire Research Centre, and meets the requirements of BS476 part 20.

Our Series 100 fire dampers are suitable for installation in both vertical and horizontal planes, as each unit is fitted with stainless steel torsion springs that guarantee closure. They are available with microswitches for blade status reporting, HEVAC/HVCA installation frames, circular spigots, and flanges for fitting to ducts or wall apertures. Maximum size is 1200mm (w) x 1000mm (h). For information on fire damper operation and reliability, please visit Engineered Air Treatment online.

Fixed Blade Louvres

Our fixed blade louvres are made with aluminium, galvanised mild steel or stainless steel housings, all fully welded with clean flushes and dressed as necessary. Flanges are self-flanged and undrilled as standard – cleaned, primed and painted RS angle flanges can also be fitted if required. Other optional extras include powder-coated blades and BirdGuard mesh and insect mesh. Maximum size is 2500mm x 2500mm – if these size restrictions are exceeded, the louvres will be supplied in modules.

Gas Retention Dampers

Gas retention dampers have a similar design to motorised dampers, but with additional seals to minimise leakage. They are used for containing fire-extinguishing gases such as CO2 and FM200 within a system. When shut, gas retention dampers are 98% closed. They have been tested by BSRIA and meet all the requirements of BS EN 1751:1999, class 2.

Gas retention dampers are available with electrical, pneumatic and hydraulic actuators, and have a 2mm galvanised mild steel casing as standard (stainless steel and aluminium also available if required). They feature 0.7mm double skin Z-type blades with PVC coated flame retardant polyether to maximise sealing, machined bronze bushes to ensure tightness of seal between casing and spindle, and spring-loaded side shims to minimise the gap between casing and blades.

Insulated Dampers

Insulated dampers have a similar design to standard motorised dampers, but have additional seals to minimise heat loss. They also have double skinned Z-type blades that are lined with 25mm Styrofoam. Bushes are made from nylon, shims are spring-loaded, and the damper housing is made with 2mm galvanised mild steel as standard (stainless steel and aluminium housings also available upon request). To find out more about our insulated dampers, please visit our website our get in touch directly on 01162 600757.

Motorised Dampers

Motorised dampers are designed to allow the passage of air through the inlet of a generator or building. They feature Aerofoil and Z-section blades made from 22g and 18g sheets (double skinned for strength), a link bar that allows blades to open and close in parallel plain, low maintenance bushes available in nylon, bronze or Oilite bronze, zinc-plated spindles, and ½” sq Fingerguard mesh as standard.

Gravity Flap Dampers

Our Gravity Flat Dampers are designed to release pressure build up in containers or buildings. Casings are made of pre-galvanised mild steel, aluminium, 304 stainless or 316L. We can provide the specifications you require by using gauges of different thicknesses. Flanges come self-flanged and undrilled and can be fitted as required. Bushes are made of nylon, bronze or oilite bronze and spindles of stainless steel 304 or 316, aluminium. Blades can be arranged in unison for turbulent air conditions and, if needed, counterbalanced to reduce pressure loss. Visit our website for further details on our Gravity Flap Dampers.

Low Temperature Dampers

Low Temperature Dampers are for use in lower temperatures (for example -40°C), but otherwise work in the same way as manual or motorised dampers. We offer electrical, pneumatic and hydraulic actuation. Casing is 2mm galvanised mild steel as standard, with stainless steel and aluminium also available. The double skin, ‘z’ type blades are fitted with PVC coated flame-retardant polyether. Our machined low temperature bronze bushes provide a good tight seal between casing and spindle. Spindles are of stainless steel, so are durable and long lasting. Optional heater jackets can be fitted and the damper can be lined with styrofoam, ensuring the mechanism remains within a certain temperature. There is more information on our Low Temperature Dampers on our website.

Manual Dampers

Manual Dampers are designed to allow the passage of air through the inlet of a generator of building. It is important that this can be shut off at any time. Our Manual Dampers feature a fully welded casing and aerofoil and ‘z’ type blades, which are extra strong, being double skinned. A link bar allows the blades to open and close in a parallel plane. We use low maintenance bearings for durability. Flanges are supplied self-flanged and undrilled as standard. The standard temperature range for our Manual Dampers is -20ºC to 50ºC. However, enhanced oilite bronze bushes can increase this range to -40ºC to 150ºC. Visit our website for more details and information about our Manual Dampers.

Sandtrap Louvres

Our Sandtrap Louvres are designed to ensure that large particles, such as sand grains or dirt, are not allowed to pass through and into structures. We provide standard casing of pre-galvanised mild steel. We can fit your speficications by using thicker gauges. Casings are fully welded with welds cleaned flush and dressed as required. Flanges are self-flanged and undrilled as standard. These Sandtrap Louvres are highly efficient, providing reliable protection from large particles. You can learn more about these louvres by visiting our website.

Acoustic Weather Louvre

Our Acoustic Weather Louvres are suitable for a range of applications from visual screening to exterior cladding. Casing can be constructed using 2mm-3mm Pre-Galvanised Mild Steel, Aluminium, 304 Stainless Steel or 316L Stainless Steel. The blades are lined with non-combustible rockwool and faced with fibreglass perforated sheet. Our louvres feature 1/2" sq mesh finger guards or insect mesh as standard. We also offer our customers the opportunity to select the finish - either self-colour or powder depending on their individual requirements. The standard temperature range for our Acoustic Weather Louvres is -20°C to 50°C. and sizing is kept between 1000 and 1200 FPM (or under 5m/s).

Counter-Balance Dampers

Our high-quality Counter-Balance Dampers are designed to release the pressure build up in a container and building to close under gravity/weight or pressure spring when not in use. The casing is constructed with Pre-Galvanised Mild Steel as standard though we also offer the option of Aluminium, 304 Stainless Steel or 316L. Flanges are self-flanged and undrilled as standard. Bushes are available in Nylon, Bronze or Oilite Bronze and Spindles in Stainless Steel 304, 316 or Aluminium. In instances of turbulent air, blades can be interlinked to rise and fall in unison. They can also be counter-balanced to reduce pressure loss.

Metal Water & Dust Eliminator

We supply top-of-the-range Metal Water & Dust Eliminators which by definition, are designed to protect against water and dust. This is achieved using R17 filter pads which offer protection against low-pressure jets of water from all directions. Casing is constructed using Pre-Galvanised Stainless Steel, but thicker gauges can be used as necessary in order to achieve individual specifications. Blades are designed with 'V' type arrangement and Flanges are self-flanged and undrilled as standard. The Eliminators also feature standard 1/2”sq Mesh finger guards. Insect mesh is also available. We also offer powder coating on blades and casing to suit individual specifications.

PVC Water & Dust Eliminator

Our PVC Water & Dust Eliminators are tested to BS EN 60529:1992. They are designed to effectively protect against ingress of solid foreign objects and water. Casing is constructed using Pre-Galvanised Stainless Steel, but thicker gauges can be used as necessary in order to achieve individual specifications. The blades have been specially designed using extruded PVC Material. Flanges are self-flanged and undrilled as standard. The eliminators feature 1/2" sq mesh finger guards as standard, but insect mesh is also available. The standard temperature range is -5°C to 60°C.

Details

Info

| Registration Number: | 01725555 |

| VAT Number: | GB372 2831 56 |

| Registered at Companies House: | 23 May, 1983 (41 years and 10 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Company Certifications

| ISO 9001:2015 - Quality management systems – Requirements |

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Total Industrial Maintenance Ltd

- Safety Audit Uk Ltd

- Mihab Consulting Ltd

- Q Locum Ltd

- Wild Goose - Media Ltd

- Roller Mop Buckets

- HOLME HOUSE FARM MANAGEMENT COMPANY Ltd

- Vicarage Gardens (Bromsgrove) Management Company Ltd

- Strathkelvin Instruments Ltd

- Magna Electrical Installations Ltd

- Articulated Boom Lifts

- Waste Recycling Technologies Ltd

- Yew Tree Farm Enterprises Ltd

- Brooklyn House Residents Company Ltd

- Ferrous Metal Recycling

- DURSLEY

- Walker Spencer Smith Ltd

- MMA Welders

- EMS Cleaning