- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Dean Group International Ltd

Overview

Products

Dean Group International (DGI) is one of the UK’s leading manufacturers of investment castings. Established in 1972, we have over 40 years of experience designing, developing, producing and delivering high quality cast products and components for use across a multitude of applications. Key sectors supplied by DGI include construction, transport, automotive production, electronics, defence, architecture, engineering, ironmongery, agriculture, hydraulics and general manufacturing – these are just some of the industries with which we work on a regular basis.

Using a combination of industry experience and technical know-how, we’re able to design and develop products, parts and components to meet just about any requirement. We understand your problems and appreciate your ideas, and we’ll spare no pains to solve the former and bring to fruition the latter. Everything we do is aimed at providing practical, cost-effective solutions based on the demands of each application. To achieve this, and to ensure our customers are never disappointed, we maintain constant communication throughout the design and production stages.

Over the years, DGI (formerly known as MIC) has gradually diversified its operations in order to improve and expand its product and service offering. Although premium grade investment castings still form the core of our operations, we also now offer commercial grade investment castings, sand castings and die castings, as well as various secondary services such as machining, heat treatment, plating and polishing. The one thing that unites all of our products and services, however, is quality.

To find out more about DGI and the services we offer, please visit us online or contact us directly on 0161 775 1633.

Premium Grade Investment Castings

Investment casting is at the heart of everything we do. Over the years we have produced premium grade castings for all manner of applications, some of them a lot more complex than others. But however complicated the design, you can trust DGI to provide a quality finish. We use the very best raw materials to create fine tolerances, superior surface finishes and repeatable castings in a range of shapes and sizes. The investment casting process itself gives an immense amount of design flexibility and allows the production of near-net shapes with precise accuracy and detail on holes, lettering, threads, serrations, etc. It also allows for a choice of alloys and accommodates both high and low volume requirements. For more information on the investment casting process and the benefits it brings, head over to DGI online or contact us on 0161 775 1633.

Commercial Grade Casting

Commercial grade investment casting is a process that offers many of the same benefits as premium grade investment casting, but at a reduced price-per-piece. However, commercial grade castings will generally have slightly rougher surfaces and wider tolerances. There are also not as many choices when it comes to material selection. If you would like to know exactly which alloys can be cast and how close tolerances can be, please visit our Investment Casting information page at DGI online.

Sand Casting

Sand casting is probably the most commonly employed casting process. The relative abundance of sand and clay minerals means material costs are reasonably low, as are those of tooling. Overall, it is a comparatively inexpensive process that offers a good combination of design flexibility and casting quality. In particular, the low cost of tooling makes it ideal for low to medium volumes. Sand casting is generally employed in situations where the close tolerances and fine finishes offered by premium or commercial grade investment casting are not strictly required.

Gravity Die Casting

Because investment casting has relatively low start up costs (particularly on the tooling), it is often the most economical way of getting a product to market. However, once volumes start to grow, the process becomes a lot more costly. In such situations, many clients prefer to switch to gravity die casting, which offers a reduced price-per-piece in comparison. Incidentally, it also allows for the production of castings with more intricate core designs, which is another reason why many customers choose it over investment casting. For more information on the gravity die casting process, head over to DGI online or contact us directly on 0161 775 1633.

Product Finishing

In today’s day and age, customers expect not just raw castings but completely finished items that are ready for use, installation or application. Of course, we’re more than happy to meet these demands if required. The benefits of having just one supplier handle all aspects of manufacturing are obvious – less administration, more control over the process, less WIP and reduced overheads. The result is less stress, greater visibility and improved profits. As well as a range of finishing procedures, we’re able to carry out full product assembly, including riveting, welding and fitting of ancillary parts.

Heat Treatment

DGI have facilities for carrying out a range of heat treatment procedures, including:

- Hot Isostatic Pressing (HIP)

- Vacuum heat treatment

- Annealing & solution annealing

- Normalising

- Hardening and tempering

- Case hardening

- Induction hardening

- Carbonitriding

To find out more about heat treatment and its advantages, visit DGI online or contact our service team on 0161 775 1633.

Machining

This was one of the first post-casting processes we offered after deciding to add finishing to our service portfolio many years ago. Back then we had just a few manually operated machines - today we have a collection of state-of-the-art 3D CNC machining centres enabling us to carry out a variety of procedures, including:

- Turning

- Milling

- Drilling

- Tapping

- Reaming

- Grinding

- Spark erosion

Find out more about our machining capability by visiting DGI online.

Sub-assembly

Need your components assembled and ready for the next stage of production? No problem. At DGI we regularly carry out sub-assembly work on behalf of our clients. You can find some examples of products assembled by DGI engineers on our website. If you would like to find out more about our sub-assembly services, please contact our service team on 0161 775 1633.

Surface Treatment

DGI engineers are also able to perform a range of surface treatment procedures to enhance mechanical and chemical properties, to improve surface appearance, or both. Surface treatment facilities used at our manufacturing plant include:

- Shot blasting

- Mechanical polishing

- Electro polishing

- Painting

- Plating

Design & Development

At DGI we NEVER manufacture anything that hasn’t been carefully designed and developed. It is absolutely critical that products are actually ready for manufacture before the casting process begins. Of course, we’ll help you to make sure that they are. Development is carried out in close consultation with your design team and tends to happen in the following stages:

- We analyse your drawing data, ideas or samples, assessing commercial viability and providing a preliminary evaluation of the costs involved.

- Assuming you wish to proceed, we’ll invite you to our facility in Manchester or arrange a meeting at your headquarters where we can discuss the project in more detail and decide upon the most appropriate manufacturing process.

- Next we’ll develop 3D CAD models for casting simulation (if not already provided by yourself). At this point we’ll also produce a firm priced quote on the project.

- A prototype of the casting will then be made. This stage is optional: you may wish to go straight to hard tooling.

- An engineered study is conducted to optimise the design of the casting, ironing out any issues so that it is ready for manufacture.

Manufacturing

Once the design is ready, we’ll set the wheels in motion and begin producing castings of the very highest quality. The primary function of our manufacturing facility is to produce investment castings for customers with the following requirements:

- Small to medium casting runs

- Infrequent order patterns

- Short lead times

- Fast prototypes

- High quality, close tolerance, UK-made components

Our facility is also equipped to handle large volumes of castings from our approved partners in China. Our large storage capacity is particularly beneficial to large customers who need products delivered within days of requesting them.

Delivery

The delivery of products, parts and components has become one of the most important aspects of our service. With production schedules getting ever tighter, never has it been so critical for us to meet our clients’ delivery deadlines. With the ability to operate to various Kanban systems, we ensure your castings arrive at the right time as well as the right price. Find out more about how we ensure a constant supply by visiting DGI online.

Details

Info

| Registration Number: | 01062820 |

| VAT Number: | GB146 3074 78 |

| Registered at Companies House: | 26 July, 1972 (52 years and 8 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: |

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Company Certifications

| ISO 9001:2015 - Quality management systems – Requirements |

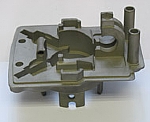

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Phoenix Hair & Make Up Ltd

- Ezl Marketing Ltd

- Boddingtons Plastics Ltd

- Road Safety Systems Ltd

- DULIEU BUILDERS Ltd

- Foreman Financial Services Ltd

- Has Resources Ltd

- Dorsetware Ltd

- Mondiale Negoce Ltd

- HAOK Ltd

- Ng Battersea Ltd

- Turner & Price Ltd

- Ceiling Roses

- Tyre Wholesalers

- Plasterers' Products

- THE R & A FOUNDATION

- Mantracourt Electronics Ltd

- WILSON'S BOOKKEEPING LTD

- LONDON