- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Zwick Testing Machines Ltd

Overview

- Mr Alan Thomas - Marketing Manager

Products

Zwick Roell is a renowned company that has been providing the industry with outstanding technical services for more than 150 years. Here at Zwick we strive to design and create innovative machinery and equipment that will guarantee reliable and accurate test results. Our success is reflected in our position as world leaders in static testing as well as our significant growth and recognition in fatigue strength and testing systems.

We provide testing machines and equipment for a wide range

of materials, industries and applications including plastics, metals,

automotive, medical, academia, textiles, paper and cardboard, food and

packaging, mechatronics, building materials, springs, composites and the solar

industry.

Our incredible team is continually researching and

developing testing methods and machinery in order to create testing machinery and

equipment of the highest standards. We are proud to boast more than 110 employees,

a facility in Ulm, Germany as well as additional facilities in America and

Asia.

Our equipment is manufactured to incredibly high standards

and our ‘Made in Germany’ quality standard is based on the Quality Management

System which is ISO 9001 certified by TUV. Our products are also compliant with

the EC Machinery Directive and all other necessary guidelines and standards that

enable us to label our testing machines as CE certified.

Please take a look at our website to find out more about our

first class testing equipment or please do call our friendly team at Zwick who

will be happy to provide all the information and advice you may need.

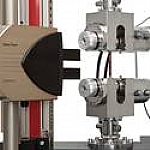

Static Materials Testing Machines

We are pleased to supply a fantastic range of static materials testing machines. These machines have been designed and manufactured for the testing of tensile, compression, shear and torsion tests and are used to test a range of materials and components. Our range of static materials testing machines includes:

Testing Machines to 5kN: Zwicki-Line single column

testing machine for tensile, compression and cycle testing up to 5kN.

Testing Machines from 5kN to 250kN: these testing

machines are specially designed for demanding testing situations.

Please visit our website to view the complete range.

Testing Machines For Determining Durability

We also supply a range of state of the art testing machines for determining the durability of components or a complete product. The range features single testing actuator types to servo-hydraulic testing machines suitable for multi axial fatigue tests. They cover a load range from 5kN up to 2500kN. To complement these machines we offer an individual module suitable for all fatigue testing requirements. This module features actuators, hydraulic power packs, distribution units, load frames and other accessories. Our testXpert® testing software also provides support during setup and performance of tests.

Automated Testing Systems

Our range of automated testing systems provides complete testing solutions in one, thus reducing throughput time. As the global leader in robotic testing systems we have developed a series of extensive and highly modular solutions. These testing systems enable users to carry out tests in a rational and reproducible way. Alongside our standard range we are also pleased to offer a bespoke service whereby we can customise existing designs to meet specific customer requirements. Our first class testing solutions are recognised all round the world for their accurate and reliable results.

Specialized Test Equipment

Here at Zwick we supply the industry with a range of

specialised test equipment. The range includes:

Machines for Static Torsion

Testing: these materials testing machines are used for single or multi-axial

torsion tests.

Biaxial Testing Machines: these testing machines are used

for two-axis tensile tests.

Sheet Metal Testing Machines: these testing machines are

used to test and evaluate the ductility of sheet metals.

Electro-Mechanical Testing Actuator: these testing

actuators are suitable for tensile and compression applications and can be

integrated into testing devices in various configurations.

Single Screw Testing Machines: these testing

machines are used mainly for tests where load-frame stiffness is subject to

particularly high demands.

Testing System for glow-wire tests: a

semi-automatic system used for glow-wire tests on plastics.

Hardness Testing Machines and Instruments

We offer a comprehensive range of hardness testers suitable for use with a range of metals, plastics, rubber and special materials. Our range of machines and instruments includes:

Universal Hardness Testing Machines and Instruments: these

versatile machines can be used for more that just one testing method and for a

wide range of applications.

Vickers Hardness Testers: these testing instruments are

suitable for various load ranges and are supplied with differed types of

equipment to suit different applications.

We also offer Rockwell Hardness Testing Machines,

Instrumented Indentation Testing machines, Portable Hardness Testers and Shore/

IRHD Hardness Testers.

Pendulum Impact Tester

We are pleased to offer pendulum impact testers or falling weight testers for impact tests. Impact tests are accelerated tests which provide users with an indication of the behaviour at fracture of materials or components when subjected to accelerated loading and at changing temperatures. Our range of machines includes: HIT Impact Testing Systems up to 50 joules, RKP 450 – Pendulum Impact Testers up to 450 joules and PSW 750 – Pendulum Impact Testers up to 750 joules. Please visit our website to find out more about these systems. We have also included videos of these systems in action so please do take a look.

Drop-weight Testers

We also offer a fantastic range of drop-weight testers. These are designed for accurate drop-weight tests on plastic or metal materials and also for pre-damaging of composites for CAI tests. Our range of testers includes: Drop Weight Testers 230 joule (two versions available to suit different application requirements), Pellini Drop Weight Testers (for investigating the tendency to brittle fracture of steels and for comparative evaluation of crack arrest behaviour to ASTM E208 and SEP 1325) and High Energy Drop Weight Testers from 20,000 joules (for testing and evaluating fracture surfaces of ferritic steels).

Modernizations

Here at Zwick our extremely talented team is able to provide excellent modernisation packages for a wide range of materials testing machines. During the last 20 years we have transformed thousands of materials testing machines into state of the art models with specific characteristics. We offer Retroline modernisation packages for Electro-Mechanical Static Testing Systems, Hydraulic Static Testing Systems, Servo-hydraulic Dynamic Testing Systems and Virbophores. These systems are created along with assured service and support for the entire system for a minimum of ten years, full compatibility with a comparable new machine, re-use of virtually all existing accessories and compliance with all safety relevant legal requirements.

Melt Plastometers

Our range of melt plastometers has been created to suit different application types. Alongside our standard range we all tailor plastometers/ melt flow testers to customer requirements. Our standard range includes:

Aflow Extrustion Plastometer/ Melt Flow Tester: designed

specifically for laboratories with high specimen throughput. This model suits

all common worldwide standards including ISO 1133 and ASTM D 1238.

Mflow Extrusion Plastometer: these models are used to

determine the melt mass flow rate (MFR).

Cflow Extrusion Plastometer: these models are designed to be

stand alone instruments for MFR determination.

HDT/Vicat

Our HDT/ Vicat range features:

HDT/Vicat Allround: designed and created for convenient testing in research and

development, goods inwards checks and product monitoring. They are also used

for education and training purposes.

HDT/ Vicat Standard: these instruments are suitable for

goods inwards checks and product monitoring as well as for education and

training purposes.

Vicat Dry: the Vicat Dry is an oil free measuring system for

clean and odour-free operation. Different versions are available featuring

either two or six measuring stations to suit different requirements.

Pre-Owned

Alongside our new products and systems we are also pleased to supply various pre-owned testing machines and equipment. All items are fully compatible with new machines (operation, range of application, service reliability, future-proofness, warranty and more). Older machines are modernised and brought up to date where required in line with relevant safety standards and guidelines. Please visit our website to view our current range of pre-owned machines and pre-owned equipment.

Testing Software

Zwick offers a range of electronics for static testing systems and dynamic testing systems.

Electronics for Static Testing Systems: we supply our new

testControl II measurement and control electronics for precise, reproducible

test results. These electronics feature new drive technology, high measured

value acquisition rates, a high level of modularity and a high safety standard.

We also supply testControl electronics. All new developments can be integrated

in this system.

Electronics for Dynamic Testing Systems: we supply the new

testControl II for use with servo-hydraulic testing machines as well as

Controller HydroWin 96xx for static, quasi-static and dynamic tests on

materials, components and complete structures.

Measurement And Control Electronics

Please visit our website to find out more about our measurement and control electronics. We are pleased to present our fantastic new testControl and testControll II testing systems. These systems are suitable for static and dynamic testing. For further information and advice please contact our technical team who will be happy to help.

Xforce Load Cells

Our Xforce load cells are widely used for tensile, compression and flexural/ bending testing as well as through-zero cyclic testing. The design of these load cells is based on the rotation-symmetric or axis-symmetric principle making it highly insensitive to transverse forces. These robust load cells can withstand loads up to 300% of their capacity without mechanical damage and up to 150% without zero shift. Xforce load cells meet all five criteria of the accuracy classes according to ISO 7500-1 over a wide measurement range.

Extensometers

We offer an excellent range of extensometers featuring different resolution levels, measuring principles and measurement travel. Our non-contact extensometers can be used right up to break without risk of damage. Examples include videoXtens extensometer, laserXtens extensometer and lightXtens extensometer. Our contact extensometers are designed for direct extension measurement in tensile tests, flexure tests or alternating load tests. The range includes extensometers with sensor arms, digital and analog clip-on extensometers and extensometers for compression tests and flexure tests.

Specimen Grips

Our range of specimen grips features different designs, test load ranges and test temperatures to cover the major application ranges of plastics, metals and component testing. The range includes screw grips, wedge grips. Wedge-screw grips, hydraulic grips and power packs, pneumatic grips and control unit, grips for screws, shoulder head and threaded head, pincer grips, special grips for tensile tests, test fixtures for compression tests, test fixtures for flexure tests, test fixtures for paper and board, test tools for texture and packing, test fixtures for multi-channel spring testing, test fixtures for solenoids actuators and abrasion tests. Please visit our website to find out more about items in these ranges.

Climate And Temperature Testing

Temperature Chambers: for research and development – temperature range of -80 up to +250 degrees C.

High Temperature Furnace: used in a temperature range of

+200 up to +1600 degrees C.

37 degrees C Temperature Chamber: an optimal solution for

testing materials to human body temperature.

Media Container with Temperature Control Unit: suitable for

static and servohydraulic testing machines, applications in media such as

saline solution, ethyl alcohol, blood and more. The container can easily be

moved to enable the clamping of specimens outside the liquid medium.

Please visit our website to find out more about our climate

and temperature testing solutions.

Specimen Preparation

Optical Measurement Device - Notch Vision: for accurate results in impact testing. Measurements are performed in three to five seconds and a tolerance monitor signals any deviation. Dimension measurements can be loaded and stored with the test results in test software testXpert®.

Specimen Preparation for Plastics: various systems are available

including the ZCP 020 Manual Cutting Press, Zwick 7108 Pneumatic Cutting Press,

Zwick 7101 Manual Cutting Press, Automatic Notch Cutting Machine ZNO 2010 and

Strip Cutter for Plastic Film.

Specimen Preparation for Metals: systems include the C-shape

specimen blanking machines, O-shape specimen blanking machines and Specimen

Grinders.

Specimen Preparation for Papers: items include Paper Strip

Cutters, Circular Cutters, Fluter and Automated Edge Crush Test Specimen Saw.

Rebound Resilience

The Zwick 5109 Rebound Resilience Tester is available in two basic models for tests on elastomers and rubber to DIN 53512 (elastomers and rubber), ISO 4662 (rubber), BS903 Part A8 Method B (rubber), ASTM D 1054 Method B (Schob) and for tests on foam materials to DIN 13014 (polyether foam hospital mattresses).

The Zwick 3107 Ball Rebound Tester is designed to determine

the rebound resilience of foams to DIN EN ISO 8307 and ASTM D 3574 as well as

latex rubber to JIS 6382.

More information about these testers can be found on our

website.

Training and Seminars

Please visit our website to view or download product information, industry brochures and video materials on our products, applications and customer services. Please see our training video ‘Friction properties on spaghetti packaging’ for a first hand tutorial for the testing of friction properties on spaghetti packaging.

Consulting

Please contact our team of experts for further information regarding all of our products and services. Find out how we can help you.

Installation and commissioning

Please also call the team for installation and commissioning information. Our team will be happy to answer any queries you may have.

On-site Support

Please also get in touch for further information about our on-site support services. All of our services are offered at competitive prices. Our highly skilled engineers work with skill and ease to solve all of your technical problems.

Spare Parts Availability

We hold large amounts of spares in stock at any one time in order to meet urgent requests as quickly as possible. Please contact us to find out more about our spare parts availability and options.

Preventive Maintenance

We recommend regular maintenance of your testing machines to ensure everything is running smoothly and to guarantee the accuracy and reproducibility of results. Our highly trained team provides maintenance services in accordance with DIN 31051 from a single source, from maintenance and inspection to overhauling and DKD calibration. All maintenance, inspections and calibrations are offered at a fixed cost and feature free access to our support desk for advice regarding applications, test procedures, test configurations and hardware and software operation. We manage maintenance schedules and contact you to arrange a convenient date.

Calibration Services

Our calibration lab is DKD accredited and all calibrations are performed to the current standards and regulation of the Physical-Technical Federal Agency. We can present verification documents displaying the measurement results in accordance with ISO 9001 – DKD certificates can also be presented. We offer different calibrations to suit different requirements: factory calibrations (Zwick calibration certificate), an ISO calibration (Zwick calibration certificate with documentation to verify measurement equipment monitoring in accordance with ISO 9001) and DKD calibration (DKD calibration certificate).

Our team offers a planning service whereby it keeps track of

calibration intervals for you so you.

Contract Testing

Zwick offers periodic inspections of machines and accessories to maintain condition and ensure everything continues to run smoothly. We schedule inspections and contact customers ourselves so they don’t have to worry about anything. To find out more about our contract testing, please contact us at Zwick.

Machine Relocation

Please contact the team at Zwick to find out more about our machine relocation capabilities. We look forward to hearing from you.

Plastics

Thermosetting and Thermoplastic Materials: tensile test for plastics, flexure test, impact test, melt flow test, determination of HDT and Vicat softening temperature, hardness test, automation.

Thin Sheeting and Plastic Films: we offer a range of testing

equipment suitable for mechanical testing.

Soft Foams: we are world leaders in this area of testing. We

can easily test large foam sections using our C-Frame testing machines, while

our testXpert foam testing software covers all requirements for determining

compression stress value, indentation hardness, compression characteristics and

tear growth characteristics.

Please visit our website to view our complete range of

testing equipment suitable for plastics.

Metals

We also offer various testing equipment for a range of metal types:Heavy Plate: testing methods include hardness testing, tensile testing on metal, robotic testing systems for tensile tests, fracture mechanics Klc determination, charpy impact testing and Pellini drop-weight testing.

Strip/ Sheet: tensile test with r and n value, biaxial test, 3 point flexure test and high temperature tests.

Thin Sheet: tensile tests with r and n value determination, ductility tests, draw bead test on steel sheets and high speed tests.

We also provide testing equipment for other types of metal equipment including bar and rod, sections and reinforcing steel, wire and cable, pipes, castings and forgings, fasteners and standards.

Textiles

Zwick offers various testing equipment for the testing of fibres, yarns and threads, textile fabrics, geoplastics and geotextiles, straps, belts, ropes, cordage and thermal insulation materials. Examples of testing equipment and methods include tensile testing thread, tensile test on multi-filament thread, tensile test on 2-ply thread, tear resistance, seam slippage resistance, bursting strength, needle pull out resistance, static puncture test, adhesion testing and compression testing. Please visit our website to find out more about all of these testing methods and machinery.

Springs

Springs are essential for the functioning of mechanical and electro-mechanical systems. Engineering springs must absorb impacts and vibrations, distribute and counterbalance forces, maintain pre-tensioning, maintain a defined position or attitude, measure and regulate forces and moments. Various testing methods are used including Uniaxial Testing of Helical Springs, Multi-Channel Spring Testing System, Clutch Testing – Axial, Tests on Pneumatic Springs at Various Temperatures and Characteristics of Rubber/ Metal Dampers. Please visit our website to find out more about our testing machines and equipment.

Details

Info

| Registration Number: | 01432602 |

| VAT Number: | n/a |

| Registered at Companies House: | 22 June, 1979 (45 years ago) |

| No of Employees: | n/a |

| Annual Turnover: | 10-20m |

| Parent Company: | Zwick Roell Group GmbH |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Questions

Additional Information

Company Certifications

| ISO 9001:2015 - Quality management systems – Requirements |

Products & Services

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Infinitely Variable Speed Motor Control Systems

- Assessors Group Ltd

- STACK DIM SUM BAR Ltd

- Computer Chassis

- Bespoke Envelopes

- H & S Jewellery Ltd

- Profile Bending

- Large Bore Hose

- Green Financial Services Ltd

- PINK HYDRANGEA LTD

- Design Engineers

- Thai Arts Ltd

- Disposable Sterile Medical Products

- Companies beginning with S

- Walsall Diy Ltd

- Xerosec Ltd

- Ionoco

- Aura Gas Ltd

- Twenty Seven Four (UK) Ltd