- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Wymark Ltd

Overview

Products

Wymark Ltd specialises in the supply of high quality Greasomatic and associated products for maintenance engineers and OEMs. The Greasomatic range is designed for use in various industries such as pumps and compressors, oil refineries, quarries, pharmaceutical, glass, airport, steelworks, ships, bakeries, cement plants and many, many more. It is also suitable for use in mining and petrochemical industries and has been approved by CERBERUS (Mining Acceptance Services Ltd) as a single point lubricator. Greasomatic is a self-ejecting canister of lubricant that screws into a grease nipple socket or lubrication point and discharges content in a controlled, continuous flow for a predetermined period between one and twelve months. The Greasomatic is completely self-contained and does not require pumps, motors, electricity or compressed air in order to work. Once activated it will work effectively until its specific lifespan is over at which time it can be replaced quickly and easily with a new model. Greasomatic is a highly effective solution for lubricating various applications including chain-drives, chain conveyors and slide-ways. Alongside our Greasomatic range we also provide a range of fittings and accessories. To find out more, please visit our website or contact us at Wymark Ltd for further information.

Greasomatic

Greasomatic lubricants are being used in various industries all around the world for simple, efficient and economic lubrication solutions. The Greasomatic self-ejecting canistor discharges content at a continuous rate for a pre-determined length of time between one and twelve months. The Greasomatic also features a pressure release valve to protect against build-up in the event of a blocked greaseway. If a blockage occurs and the pressure of the Greasomatic is unable to clear it, the valve will open to allow the lubricant to escape and prevent excessive pressurisation. To view diagrams and detailed specifications, please visit our website or contact Wymark Ltd.

Accessories & Fittings

Alongside our range of Greasomatic lubricants we also provide a wide range of accessories and fittings. Examples of the range include adaptors, unions, T-pieces, Bends, rigid extension tubes, nylon extension tubing, copper extension tubing, tube coupling, mounting brackets, non return valves, brush fitments, ball valves, and various mounting assemblies. Our range of fittings and accessories has been created to provide users with parts that will not impede the flow of grease. Once the accessories have been placed for installation only the Greasomatics will then need to be replaced at the predetermined time.

Lubrication Systems

Our lubrication systems are designed, supplied and installed to suit almost all kinds of industry applications from steel rolling mills, to soap packaging machines, to mobile plants. The Greasomatic lubrication system has been designed to provide controlled lubrication 24 hours a day, seven days a week for a controlled length of time. The lubrication discharges from a centralised pumping station through a pipework network and a range of measuring devices in order to lubricate individual bearings effectively. Examples of our lubrication systems include dual line, single line progressive, single line injection, single line metered flow and automatic spray systems for oil and grease.

Lubricants

The Greasomatic range has been expertly designed and created to provide users with first class results in all types of environments. The range features various greases with outstanding waterproof properties, enclosed gear lubricants, open gear lubricants, wire rope lubricants, valve lubricants, anti-seize lubricants and electrical equipment cleaners. These can be supplied in different formats such as drums, kegs, cans, cartridges and aerosol spray cans. Please visit our website to view detailed information and images.

High Performance Lubricants

We supply a wide range of high performance lubricants. Examples of the range include anti-seize compounds (lead-free anti-seize, nimonic anti-seize, graphite anti-seize and aluminium anti-seize), assembly lubricants (assembly lubricant 500 and assembly grease MOS2), chemical resistant grease (chemical resistant grease NLGI 2), food-clean environment grease/ oils, general lubricants, heavy duty greases, high temperature chain oils, high temperature greases, hydraulic oils, industrial EP gear oils, low temperature greases, open gear grease, slideway oils, valve grease, vibration resistant grease, waterproof grease and wire rope lubricants. Please visit our website to download information sheets.

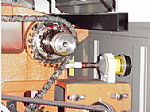

Chain Lubrication

Greasomatic lubrication is widely used as a cost-effective method of lubricating chain-drives and slide-ways. By combining Greasomatic with a Greasomatic brush fitment and suitable fittings from our Greasomatic accessory range, it is easy and inexpensive to create effective chain lubrication systems. Please visit our website to download and view technical information.

Applications

Greasomatic lubrication can be used for all kinds of industry applications including pumps and compressors, oil refineries, quarries, crushers and shakers, sawmills, foundries, glass, airports, plastic moulders, steelworks, cement plants, automotive, conveyors, large electric motors, chemical plants, conveyors, laundry equipment, dockside equipment, wood processing, mechanical robotics, ships, bakeries, brickworks, printers and many, many more.

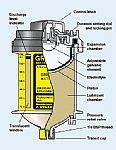

How the Greasomatic works

The Greasomatic self-ejecting canistor discharges content at a continuous rate for a pre-determined length of time between one and twelve months. Once activated it will work effectively until its specific lifespan is over at which time it can be replaced quickly and easily with a new model. The Greasomatic also features a pressure release valve to protect against build-up in the event of a blocked greaseway. To view diagrams and detailed specifications, please visit our website or contact Wymark Ltd.

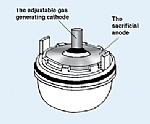

Discharge Information

The discharge rate of the Greasomatic is controlled by a rotating know and a linked dial. The duration can be set for 1, 2, 3, 4, 6, 8, or 12 months. The rate at which the lubrication is discharged depends on the rate at which it generates gas which is, in turn, governed by the degree of exposure of the galvanic element’s gas generating cathode to the electrolyte in the presence of the sacrificial anode. The adjustable galvanic element is held in place in the underside of the cap and connected to the control knob. By turning the control knob, the rod shaped cathode protrudes from the seating to provide the appropriate rate of gas generation for the discharge of lubricant that is set on the dial.

Fittings & Fillings

The Greasomatic has a thread so that it can be screwed by hand to fit securely into a grease nipple socket. Various adaptors and accessories are available for the most effective lubrication assembly. Our extension tubes enable installation at a distance away from the lubrication point. Other accessories in the range enable two or more units to be coupled together for increased lubrication supply to the bearing. Greasomatic is versatile in that it does not need to be mounted in an upright position and works effectively both indoors and out.

Standard Grease Fillings

We are pleased to offer a comprehensive range of standard grease fillings. Visit our website where you will see information about the following: Grease MP, which is a multi-purpose grease, boasting a long life, excellent adhesive qualities and water-resistance; Grease FG is specially formulated for use in the processing of foodstuffs and pharmaceuticals; Grease HT provides maximum lubrication at very high temperatures. Also available is Grease EPM, which withstands extreme pressure conditions; Grease OG, which is particularly suitable for gears used in wet or humid conditions; Grease CS is used in chaindrives and slideways subject to difficult conditions and Grease WP, a high performance waterproof product. All our standard grease fillings are of excellent quality and perform well in use.

Standard Oil Fillings

All our standard oil fillings are produced specially for Wymark by leading manufacturers who exercise stringent quality control. Available within the range are oil fillings for various different purposes including general purpose, airline lubrication, use with foodstuffs and pharmaceuticals, and use in slideways and chaindrives. Our standard oil fillings deliver the quality and performance for which we are well known, You can learn more about each of the products on our website.

Expertise

Each and every point lubricator we provide is carefully hand-assembled in our factory in Cheltenham. We have comprehensive and demanding Quality Assurance procedures in place to ensure the highest standards of performance, and reliability you can trust. Further, we go the extra mile when it comes to pre-sales advice and customer support. We draw on our expertise to offer information and advice to help you choose the products best suited for your particular application. We have office-based and field-based staff, so if you require a site survey, we can send our experts to you. Acknowledged industry leaders in customer service and support, we will make sure you get the best products for your installation.

Details

Info

| Registration Number: | 01460346 |

| VAT Number: | n/a |

| Registered at Companies House: | 9 November, 1979 (44 years and 5 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Brand & Trade Names

- GREASOMATIC The GREASOMATIC is a automatic single point lubricator

Company Certifications

| ISO 9001:2015 - Quality management systems – Requirements |

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Brake Components

- Whitford Ltd

- High Street Computers Ltd

- PRODUCTS THROUGH KNOWLEDGE Ltd

- Bandsaw Blades

- GR SUBS Ltd

- Choice Techniques Ltd

- Rr Property Consultants Ltd

- Companies beginning with R

- Techtronics (UK) Ltd

- Rhovanion Ltd

- Chris Morley Associates Ltd

- Kl Regan Developments Ltd

- Livewire Home Integration Ltd

- Bell Hathaway Ltd

- Coloured Polypropylene Webbing

- Floor Tiles

- CNC Tool Regrinding

- Shelters