- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Westmoreland Mechanical Testing & Research Ltd

Overview

- Mr Vinay Vaghela - Business Development Manager

- Mrs Claire Tustain - Administration Manager

- Mr John Guntrip - Quality Manager

- Mr Simon Gregory - project engineer-composites

- Mr Alan Cooper - Managing Director

- Mr Terry Cook - Operations Manager

- Mrs Baina Bain - Sales Administrator

- Mr Steve Atkins - Lab Manager

Products

Westmoreland Mechanical Testing & Research (WMT&R) Ltd offers a range of standard and special one-off testing services for customers in the automotive, aerospace, nuclear, offshore and medical industries. Our state-of-the-art facilities enable us to mechanically or chemically test almost any material in virtually any shape or form, and as one of the largest independent testing companies in Europe, we’re also able to provide a range of more specialised services in specific areas such as surface engineering technology, bonding, and corrosion. Due to high demand, WMT&R Ltd was able to double its testing capacity within the first year of operation, and we continue to expand our testing facilities to cater for an even wider customer base. We’re now able to offer excellent metallographic support, pneumatic coating, adhesion testing, chemical analysis, and also Lockheed testing - all alongside our highly popular mechanical testing services that we have run since 2003. We also operate a fully equipped CNC machine shop that enables production of test specimens onsite. Despite our rapid growth, we have never lost sight of what's important - the quality of our services are still second to none, and our levels of customer support and attention are unrivalled anywhere in the industry. So for outstanding mechanical and chemical testing and analysis services, visit www.wmtr.co.uk . If you would like to discuss your requirement with one of our experts, please get in touch on 01295 261211.

Chemical Testing

The WMT&R Analytical Lab works in close cooperation with our physical and metallographic laboratories as a problem-solving tool in case of material failures. You can also rely on our Analytical department as an independent source for reliable material overcheck testing, referee testing and product verification testing.

The use of conclusive spectrometer technology in conjunction with ICP and Graphite Furnace AA eliminates the need for lengthy wet chemical tests and thus ensures a fast turnaround.

Optical Emission Spectrometry (OES or Arc Spark) allows fast and accurate analysis of metals and their alloys in accordance with the most common quality standards required by the metal production and metal testing industries.

Composites Testing

At WMT&R Ltd, we recognise the need for specialist testing services for composite materials, and have therefore developed a number of composite-specific tests for ferrous and non-ferrous thermoplastics, thermoset polymers, fibres, filers and adhesives. These include:

- Tensile testing - 0 Degree fibre EN 2561, 90 Degree fibre EN 2597 and ASTM D 3039

- IPS testing - BS EN ISO 14129 and ASTM D3518

- ILSS testing - EN 2563

- Compression testing - ASTM D695 and ISO 14126

- ISO 527 - Determination of Tensile Properties in Plastics

- ASTM D229 - Standard Test Methods for Rigid Sheet and Plate materials used for Electrical Insulation

- ASTM D638 - Standard Test method for Tensile Properties of Plastics (unreinforced and reinforced)

- ASTM D790 - Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

- EN ISO 14125 - Determination of Flexural Properties in Fibre-reinforced Plastic Composites.

- EN ISO 14130 - Determination of apparent inter-laminar shear strength by short beam method

- EN 2563 - Determination of the apparent inter-laminar shear strength in Carbon Fibre Reinforced Plastics and Unidirectional Laminates.

For a full list of composite tests carried out by WMT&R Ltd, please head over to our website.

Corrosion Testing

Our stress corrosion testing capabilities extend to 13 frames, with capacity for loading up to 1300 constant strain specimens. Test set-up is tailored to the individual requirements of the customer. Corrosion testing services include:

- C-Ring

- Bent Beam

- Alternate Immersion in Salt Water.

- SCC of High Strength Aluminum Alloys

- Direct Tension

- Asset

- Intergranular Corrosion to ASTM G28 and A262

- Harshaw Environmental Testing

Advanced environmental testing chambers allow us to simulate humidity and salt spray. Find out more by visiting WMT&R online.

Tensile Testing

WMT&R are able to conduct tensile testing with load capacities up to 1,000,000 lbs at ambient temperature. We can also perform tests at temperatures ranging from -450°F to 2200°F in accordance with customer specifications, as well as with the following international and industry standards:

- ASTM E 8 – tension testing of metallic materials.

- ASTM E 21 – elevated temperature tension testing of metallic materials.

- NASM1312-18 (formerly Mil-STD-1312-18) – the National Aerospace Standard for elevated temperature tensile testing of fasteners, Method 18.

- NASM1312-8 (formerly Mil-STD-1312-8) – National Aerospace Standard for tensile testing of fasteners, Method 8.

- ASTM A 370 – mechanical testing of steel products.

- ASTM D 638 – tensile testing of plastics.

- ASTM F 606 / F 606 M – mechanical testing of externally and internally threaded fasteners, washers, direct tension indicators and rivets.

- ASTM D 3039/D 3039M – tensile testing of polymer matrix composites.

Fatigue Testing

At WMT&R, we’re able to conduct fatigue testing on a wide a range of materials, and have machines that facilitate the application of forces from as little as 50N right up to a maximum of 1MN. Test techniques include standard high and low cycle axial fatigue, staircase fatigue, F.C.G.R, and individual component testing. A full range of grips and fixtures means we can accommodate samples of virtually all shapes and sizes.Test data is collected electronically and can be analysed by the client or by our own analysis team using an advanced software suite. For details of test standards, please head over to the WMT&R website.

Mechanical Testing

WMT&R can carry out a range of mechanical tests, including:

- Tension and compression testing – with machines capable of applying forces up to 4447.315775 kN. Tests can be conducted in various atmospheres, including vacuum, argon, open air and liquid mediums with temperatures ranging from liquid helium to 1204°C.

- Bend testing – conducted on standard materials, welded materials and full size parts. Standard procedures include guided, semi-guided and wrap-around testing.

- Charpy & Izod Impact Testing – conducted on machines capable of measuring up to 299.4502 ft lbs, at temperatures ranging from liquid helium to 1093°C.

- Fastener testing – with facilities for testing bolts, nuts, bars, cable, all-threads, tubes, universal joints, chains and other full-size parts. Tests carried out in accordance with current fastener acts, military specifications or customer requirements.

- Drop weight testing – performed to ASTM E208.

Metallography

Comprehensive metallographic testing facilities enable us to meet all your metallography needs, from lot release and material overchecking to failure analysis and problem solving on test specimens, fasteners and finished parts. Metallographic tests carried out by WMT&R include:

- Grain size

- Macroetch

- Depth of Decarburization

- Banding/Orientation of Microstructures

- Inclusion Content

- Microhardness

- Alloy Depletion

- Oxidation Casting Mold Reactions

- Diffusion Coatings

- IGA/IGO

- Alpha Case: Wrought

- Hardness Testing (Brinell, Rockwell, Knoop, and Vickers)

- Microetch

- Case Depth

- Macro Exam

- Plating Thickness

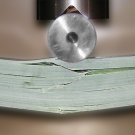

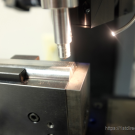

Machine Shop

WMT&R’s onsite machine shop is a key part of our service package. State-of-the-art CNC machining centres allow us to fabricate test specimens to the most exacting tolerances, and a series of roughing lathes and bulk sawing machines enable us to cut difficult and complex shapes and materials from almost any artefact. To find out more about our machining capabilities, please visit WMT&R online or contact us directly on 01295 261211.

Manuals & Brochures

Details

Info

| Registration Number: | 04623699 |

| VAT Number: | GB807 8172 19 |

| Registered at Companies House: | 23 December, 2002 (22 years and 3 months ago) |

| No of Employees: | 21-50 |

| Annual Turnover: | 2-5m |

| Parent Company: | WMTR INC (USA) |

| Importers: | |

| Exporters: | |

| Company Type: |

|

| UK Branches: | Banbury, Oxfordshire |

Opening Times

| Monday | 06:30 AM - 12:00 AM |

| Tuesday | 06:30 AM - 12:00 AM |

| Wednesday | 06:30 AM - 12:00 AM |

| Thursday | 06:30 AM - 12:00 AM |

| Friday | 06:30 AM - 06:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Company Relationships

Brand & Trade Names

- WMT&R Inc USA based HQ of the WMT&R laboratories global business

- WMT&R Ltd WMT&R Ltd the No 1 test house for materials science testing in Europe and Asia. www.wmtr.co.uk [email protected]

- WMTR International WMTR test services are globally recognised as a best in class for the Aerospace, Automotive industries

Products & Services

Gallery

Financial Information

To view more detailed financial information for this company click here.

Accepted Payments:

- A C Consultancy North West Ltd

- ROSEANGLE HOUSE NURSERY Ltd

- COMPLIANCE REFRESH LTD

- Foundation Bricks

- Labman Automation Ltd

- Althorp Homes Ltd

- Riverside Jewellery & Accessories Ltd

- Nugent Inspection Personnel Ltd

- Postcodes beginning with LS

- Van Ladder Roller Kits

- The Beechwood Estates Co.Limited

- Data-mailer Printing

- Lewis D M R Ltd

- Odx Group (Suffolk) Ltd

- Advancing Business Training Club Ltd

- Nrt Carpentry Contractors Ltd

- Grimshaw Group

- Slideway Machine Covers, Guards

- Roller Banners