- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Weldlogic Europe Ltd

Overview

- Mr Alan Kerr - Director

Products

Precision Welding Products

For over 25 years Weldlogic has lead the market with innovations in micro-TIG and micro-Plasma welding. Its range of state of the art Linear and Computerised power sources are capable of delivering precise current, voltage and travel over programmable weld schedules. Along side these power sources are a range of welding lathes, turntables and linear seam welders. The company’s philosophy is to work in close partnership with its customers, to realise process solutions that meet their exact need. Whether customisation of standard equipment or full turnkey automated machinery is required Weldlogic has the answer.

TIG and Plasma welding power supplies

PA-10/100-STD

The most accurate low current welding system on the market today performs welds on the thinnest of components. Has become the industry standard for metal bellows edge welding.

AWS-200N/400N

The AWS-200N (Advanced Welding System) is a micro processor based system designed and built to provide a high quality, economically priced, very accurate and repeatable total welding system

PT-10A Plasma Console

This Power module includes a plasma weld console, 50 Ampere plasma welding torch, torch accessory kit, water circulator and integration to the PA-10/100 or AWS systems to allow welding in either a TIG or Plasma mode.

Weldlogic supply a wide range of welding manipulators: welding lathes, welding turntables, column & boom manipulators etc. Please contact us to discuss your requirements.

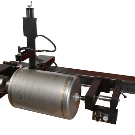

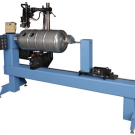

AWS 6100 Automatic Arc Welding Station

To achieve maximum welding rate and minimal labour cost, AWS-6100 Automatic Welding systems integrate a combination of standard Weldlogic products to provide a complete package. Specifically designed for precision automatic welding, 6100 systems allow circumferential, longitudinal and spot welds to be easily made with a minimum of operator skill. All components are fully integrated to create a complete "ready to go" automatic welding station.

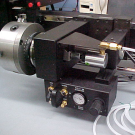

PWL-Series

Weldlogic offer an extensive range of standard and custom lathes and turntables, operating in both the vertical and horizontal planes.

Rotary welding manipulators

Weldlogic sell a broad range of rotary welding manipulators, turntables and welding lathes with capacities ranging from 100kg to 15,000kg. Custom variants are also available.

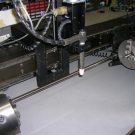

PLS Longitudinal Seamer

Weldlogic PLS Weld Seamers are designed for straight line welding of all weldable metals in thickness from .005" to 1/2" and lengths up to 10 feet.

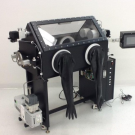

Welding Glove Boxes (Purge Chambers)

We provide both custom and standard welding glove boxes (purge chambers) suitable for use within the aerospace, medical, scientific and nuclear industries. Our welding glove boxes are manufactured from stainless steel making them long lasting and durable. By using our welding glove boxes you will achieve defect free, high quality welded joints, even on exotic materials.

Welding Accessories

Tungsten Grinders & Preground Electrodes

Our sister company Diamond Ground Products sell a wide range of Tungsten Electrode Grinders, Pre-ground & Re-ground Welding Electrodes, Fusion Electrodes and Tungsten Welding Electrodes.

Rotary welding manipulator with max load of 500 Kg and thru-hole Ø260 mm. Motorised inclination from 0° to -135° (using brushless motor).

Heavy Duty Rotary Welding ManipulatorsWeldlogic supply a wide range of heavy duty rotary welding manipulators, welding lathes and turntables, whose features include:

- CC Motor driven by tachometric dynamo or encoder, brushless or AC;

- Hollow rotating shaft with internal service pipe passage;

- Extremely rigid bearing arm, with endless screw, capable of supporting pneumatic & motorised slides;

- Pneumatic slide movement with ball bearing guides;

- Numeric control.

Further variants and customs solutions are available. These manipulators can be used as the core components of integrated custom welding systems. Please contact us to discuss your requirements.

OM-5 Oxygen Weld Purge Monitor - 0.01%The OM-5 Oxygen Purge Monitor measures the oxygen content of the backing/shielding gases during the welding process.

WeldingAccessories

OM1 Oxygen Analyser to 1ppm

The OM1 Oxygen Monitor measures the oxygen content of the backing/shielding gases down to 1ppm Oxygen. This instrument is ideal for critical applications such as the welding of Titanium and other exotic materials.

Sight Pipes

Sight-Pipes are ideal for visually inspecting orbital tube welds, typical in the semiconductor and nuclear industry. When inserted into a tube/fitting welding assembly, Sight-Pipes project a magnified image of the weld to the top of the enlarged head of the Sight-Pipe. The image seen would be similar to that produced by sectioning the tube and looking directly at the weld.

Details

Info

| Registration Number: | 03263625 |

| VAT Number: | n/a |

| Registered at Companies House: | 15 October, 1996 (27 years and 6 months ago) |

| No of Employees: | 21-50 |

| Annual Turnover: | 2-5m |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Brand & Trade Names

- Centrator Centrator specialises in the manufacture and supply of internal alignment and purging equipment used to assemble pipes and cylindrical components for circumferential welding.

- Diamond Ground Products Tungsten Raw and Pre Ground. Tungsten Grinders Fibre Optic Splicing Electrodes Cleaving Blades

- Piranha Tungsten Grinders

Products & Services

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Diginside Ltd

- ROUGE AESTHETICS LTD

- Shaw Haulage Ltd

- A Lightfoot Plumbing & Heating Ltd

- DIRECT EXPERTS Ltd

- Commercial Flooring

- Potentiometric Recorders

- Contractors' Plant Hire, Lease, Rent

- IRW ENGINEERING SERVICES Ltd

- Stablecroft Conference Products Ltd

- Sturland Ltd

- ENCELADUS ENGINEERING LTD

- Carrec Ltd

- Stainless Steel Reels

- Packaging First Ltd

- SAMSUNG HUB

- BFT Automation UK Ltd

- Aje Rentals Ltd

- Alina's Beauty Ltd