- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Vortex Valves

Overview

Products

Vortex Valves has been providing material handling solutions to industries across the world for more than thirty years. More than 10,000 companies have used products supplied by Vortex® including leading brands such as PolyOne, Dow Chemical, Nestle and Morton Salt. The company has steadily expanded throughout the years with more and more incredible products being added to the range. Vortex® has increased and developed its manufacturing facilities to meet the growing demand of the industry and now boasts an incredible 15-acre campus based in Salina, Kansas and representatives based in more than 30 countries around the world! Vortex® has patented many products and equipment that have been designed for the efficient and cost-effective processing of dry bulk solid materials. The dedicated team is committed to providing customers with innovative products of the highest quality that are designed to function accurately in dry bulk processing plants in order to reduce costs of labour and parts. Our service is exceptional and we work closely with customers before and after sales to ensure that they are completely confident using our equipment. For details of our complete range, please visit our website or contact us at Vortex Valves with your requirements.

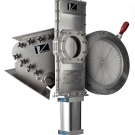

Quantum Series Orifice Gate™

Our Quantum® Series Orifice Gate™ has been carefully designed and manufactured for applications where dry bulk solids need to be processed in gravity flow, dilute phase, or vacuum conveying systems. This full flow orifice features a smooth bored valve for improved performance and decreased pressure drop across the orifice, shielded gate seat and live-loaded seals for added protection, and provides unrestricted conveying of material. Benefits of the Vortex® Quantum® Series Orifice Gate™ include self-cleaning action, no material build up, seal protected from abrasion, easy installation and maintenance, and more. For a detailed specification, please visit our website.

2-Way Wye Line Diverter™

This model has been designed for applications where dry bulk solids are processed in vacuum or dilute phase pneumatic conveying systems of pressures up to 15psig (1 barg). The Wye Line Diverter™ has been specifically designed to reduce problems that may occur which in turn increases production and decreases costs of labour and equipment. Benefits of the 2-Way Wye Line Diverter™ include the ability to shift without having to shut the blower down, a smooth bore for unrestricted flow of material, seal protection from abrasion, and more. The air cyclinder model includes a magnetic piston.

3-Way Wye Line Diverter™

The 3-Way Wye Line Diverter™ is a step up from the two-way model. It features much of the same benefits such as the ability to shift without the need to shut down the blower, smooth unrestricted flow of material, improved conveying efficiency, and more. The 3-Way Wye Line Diverter™ is available in a range of models to suit different requirements and is widely used in industries such as plastics, petrochecmials, foods, minerals, textiles, agriculture and more. To view the detailed specification, please visit our website.

4-Way Wye Line Diverter™

Our 4-Way Wye Line Diverter™ is for the process of dilute phase pneumatic conveying and has vertical or horizontal valve application. This model can be used as a diverter or converger with four lines and can be used with pressure or vacuum systems. The 4-Way Wye Line Diverter™ is a versatile system that can be adapted and modified to suit a range of applications and environments. This model is easy to install and easy to maintain and is seal protected from abrasion. Bore options range from 2inches to 6inches pipe or tube and the model itself can be constructed from stainless steel aluminium and/or carbon steel.

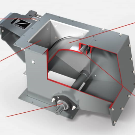

Vortex® Roller Gate™

Our Vortex® Roller Gate™ is a fantastic, cost-effective model for the handling of dry materials in gravity flow applications where positive material shut-off and dust tight sealing are required in compact locations. The Roller Gate can be altered and modified in order to meet specific application requirements in order to be increase production rates and reduce costs. Bores range from 6inches to 30inches or more and can be square, rectangular, or customized to your requirements. The Roller Gate has a narrow profile, has a positive seal for dust and fine powders, seal access ports for in-line seal replacement, seals and cam adjustable nylon rollers that are protected from abrasion, and more.

Abrasion Resistant Slide Gate

Our Titan Series Abrasion Resistant Slide Gate is a relatively new addition to the range. This model is manufactured from heavy duty steel in order to be tough, reliable and long-lasting. It provides accurate metering of abrasive materials such as whole grains, coal, metal powders, or minerals. This abrasion resistant slide gate combines the robust features of the Vortex® Aggregate Gate™ with the superior dust-tight seal of the Vortex® Roller Gate. It has replaceable AR400 liners to protect seals from abrasion and the air cylinder model includes a magnetic piston.

Vortex® Fill Pass Diverter™

The Fill Pass Diverter is for the handling of non abrasive powders, granules or pellets in vacuum or dilute phase pneumatic conveying systems with pressures up to 15psig (1 barg). The versatility of the Fill Pass Diverter means it can be modified for use in various industry applications. The Vortex® Fill Pass Diverter™ fills 'in-line' weigh hoppers as the material is conveyed pneumatically through a closed loop system. Benefits of this equipment include improved weighing efficiency and accuracy, smooth unobstructed bores for unrestricted flow of material, ability to shift without shutting down the blower, seal protected from abrasion, and more.

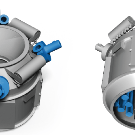

Iris Valve

This precision machined valve features a stainless control ring, metal locks and handles and controls the gravity discharge of free-flowing dry bulk material such as powder, pellets and granules from bins, bulk bags, chutes and hoppers. It has a form-fitted fabric sleeve in order to create a dust tight seal and a product barrier to eliminate material leaking into the atmosphere of coming into contact with the valve's actuating parts. This valve can be used independently or can be incorporated with other dry material handling equipment.

Vortex® Aggregate Diverter™

This range is designed to meet the demands of applications that handle material such as sand, gravel, whole grains and coal. This heavy duty equipment features an access door for internal inspection, cleaning and maintenance purposes. It also has abrasion resistant wear liners for a 'maintenance friendly' diverter. These diverters are widely used in industries such as plastics, petrochemicals, chemicals, minerals, textiles, agriculture and mining. For further information, please visit our website, or contact us at Vortex Valves Ltd.

Vortex® Gravity Vee™ Diverter

The Vortex® Gravity Vee™ Diverter is designed for applications that divert the flow of dry bulk solids in a gravity flow conveying system. This system allows material to flow through both bodies at the same time, through one outlet at a time, or can be shut off completely. It also provides accurate metering of material with optical metering controls. Features include the positive seal of dust and fine powders, seal access ports for in-line seal replacement, and seals protected from abrasion. The Vortex® Gravity Vee™ Diverter has been carefully designed and manufactured to improve production while reducing costs of labour and equipment at the same time.

Vortex® 2-Way Seal Tite Diverter™

Our Vortex® 2-Way Seal Tite™ Diverter has been designed for gravity flow applications where the material is to be diverted from one source to one of two destinations. This easy to install range features a removable access door to enable easy replacement of blade and shaft seals and for internal inspection. A selection of models is available in this range with specifications designed to suit a variety of industry applications. For further information, please contact us at Vortex Valves Ltd.

3-Way Seal Tite Diverter

The Vortex® 3-Way Seal Tite™ Diverter as you would expect diverts material from one source to one of three destinations. It features many properties of the 2-Way Seal Tite Diverter such as a positive seal of dust and fine powders, seals protected from abrasion, access door for internal inspection, cleaning, or maintenance, easy installation and maintenance, and more. The 3-Way Seal Tite Diverter has been designed and manufactured to promote efficiency and durability in production. To find out more about other models within this range, please visit our website, or contact us at Vortext Valves Ltd for further information.

Vortex® Quick Clean Sanitary Orifice Gate™

Our Vortex® Quick Clean Orifice Gate™ is a clean out of place gate valve specifically designed for frequent cleaning. It is manufactured from FDA approved materials and is USDA Dairy Standard Accepted Available. It is designed for use in industries such as pharmaceuticals, pigments, chemicals and dairy. The Quick Clean Orifice Gate™ provides a positive seal of dust and fine powders and is a perfect accessory to applications that require daily sanitation of equipment. The valve features a full-port opening and self-cleaning design.

Flex Tube Diverter

The Vortex® 2-Way Flex Tube Diverter™ has been carefully designed to eliminate the cross contamination of material by its positive seal across the closed port and the elimination of internal ledges and pockets which reduces the build up of trapped material. The Flex Tube Diverter™ features smooth, unobstructed bores for the unrestricted flow of material. Like all of our equipment this range is designed to be easy to install and maintain and forms a vital part of dry bulk solid handling systems. 2-way and 3-Way models are available.

Details

Info

| Registration Number: | n/a |

| VAT Number: | n/a |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: |

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Products & Services

Gallery

- Z.Z. Consulting Ltd

- Telescopic Steel Machine Covers, Guards

- BEAM CONSULTING LLP

- E-web Corporation Ltd

- LONGTERM PROPERTIES LTD

- Product Reliability

- Pocket Watch Pins

- Die Casting

- Mokkamo Ltd

- Rainwater Guttering

- BRISTOL

- Pipeline & Drainage Systems plc

- Steel Blanks Ltd

- The Merchant Adventurers (Gb) Ltd

- PGP FINANCE NO. 22 LP

- COME DIRT OR GRIME Ltd

- The Real Estate Finance Co. Ltd

- SRL Traffic Systems Ltd

- DREAM DAY CREATIONS LTD