- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

NPI Solutions Ltd

Overview

- Mr Kevin Priestley - Managing Director

Products

NPI Solutions are a private, independent manufacturing company providing engineering and subcontract machining services.

Although we are based in Irvine, Scotland, our decade plus of experience, combined with our network of skilled professionals have given us a growing and returning global client base. Our expertise has also awarded us involvement in a number of esteemed projects.

Our focus is with production of medium and low volumes for a variety of specialties: sheet metal fabrication, prototyping, full product build, contract manufacturing, precision machinery, PCB assembly tooling, and industrial services.

All of these different capabilities have been built up with the belief that undertaking work in-house is preferable to depending on external contractors.

Contract Manufacturing

Our contract manufacturing service delivers many benefits for clients. Those who take advantage of this service don’t have to worry about employers, finding a production facility, or purchasing equipment and materials, and avoid disruptions to work progress.

Ultimately NPI Solutions’ contract manufacturing gives our customers the time to concentrate on other areas of their business’s new product. All they have to do is pass the orders to us.

Our contract manufacturing service covers several areas: complex assembly, packaging, finishing, plastics, CNC machining, and sheet metal fabrication.

Please visit our website for more information about our contract manufacturing.

Industrial Services

As a manufacturing company offering subcontract machining services and engineering, we undertake work for a broad range of industrial sectors. These are: stencil cutting, stencilling, spray painting, screen printing, powder coating, deburring, product development, linishing, rumbling, anodising, and alocrom.

We provide these industrial services in both low volume and medium volume production scales.

Anodising

Encompassing our anodising service are a number of processes which we use for various clients using aluminium as a primary material.

Available anodising services are: hard anodising, chromic acid anodising, and sulphuric acid anodising. We frequently use selective anodising for our clients as well as processes that ‘Aluprint’ to create variations in surface printing.

There are several attractive advantages of anodising aluminium products and components. It achieves durability, different finish options and uses a safe process.

Outsourced Product Development

Our expertise has made NPI Solutions the first choice for outsourced product development for many companies.

Outsourced product development offers several important benefits. Aside from minimised development costs, it also provides customers with quality time for other areas and a quick delivery to the market. Additionally, costs of outsourcing are dramatically reduced by localising your choice as opposed to opting for an overseas team.

For more information about NPI Solutions’ outsourced product development services, please take a look at our website. Here you will also find a link to our whitepaper on why you should subcontract locally.

Prototyping

Try out your design concept with NPI Solutions’ prototyping service.

Testing a design through a built sample/early-stage model allows product companies to analyse a design and establish further improvements that may be integral to a product’s success.

The expert team here help our clients to not only develop, but also manufacture their prototype too.

One of the most significant advantages of using a prototyping service is that costs are reduced as the downfalls of a product are identified early on before manufacture and market launch time costs are wasted.

Full Product Build - Box Build

Full product build

We have a full product build service featuring the following: box build, reviews of design, reviews of manufacturing, supply chain management, KanBan manufacture, distribution, packaging design, stock holding, and compliant quality.

Box Build

NPI Solutions’ box build assembly service is an avenue for those who have a number of other important tasks to focus on. We take over responsibility of manufacturing from start to finish and in doing this, manage all of the different stages; a box build final assembly of the client’s product.

We have undertaken box build assembly for a wide range of product types including commercial, medical, and power.

Precision Machining - Heatsinks and Prepreg Manufacture

With our advanced precision machining capabilities, NPI Solutions manufacture heatsinks and prepreg for several major industries: automotive, aviation, military, and space.

Produced in our 3D CAD/CAM facility, our heatsinks and prepreg manufacture service includes 3D thermal planes, flat thermal planes, bonding, and 3D heatsinks.

NPI Solutions’ 3D heatsinks have been designed to provide protection in addition to their coding properties.

Our prepreg and tape has been deemed suitable for external and internal use and can be delivered to the client already bonded to the thermal plane.

Thermal planes

Thermal planes can be manufactured in a whole spectrum of different shapes and sizes. Select from a variety of finishes including gold.

Precision Machining - Architecture - Pig Nose Screws and Fittings

NPI Solutions manufacture an excellent range of precision machined pig nose screws and fittings: risers, pig nose bolts, pig nose drive holes, pig nose nut covers, and pig nose blanks.

Although pig nose screws are normally manufactured from stainless steel, NPI Solutions can use any material for these including plastics.

We offer bespoke solutions as part of this precision machining service for the architecture industry. Whatever quantity you need and whatever specific fixing problem you need solving, NPI Solutions will create a bespoke component.

We believe that the aesthetics of some buildings can be greatly enhanced with pig nose fixings. We often recommend these features for this reason, however when actual fixings are not necessary, pig nose blanks can be very useful for cosmetic purposes.

Sheet Metal Fabrication

Our sheet metal fabrication services take a special focus on stainless steel invisible-seam manufacturing.

There are a number of components that benefit from this type of manufacture. For instance, the outer covers of components are frequently produced using this method as their appearance is very important; stainless steel invisible-seam manufacturing delivers excellent cosmetics.

NPI Solutions’ sheet metal fabrication service has the ability to manufacture products from a multitude of materials giving this service great flexibility.

This fabrication service involves several different elements which all take place in our dedicated precision machining facility: computer aided design, computer aided manufacturing, CNC laser cutting, press brake forming, spot welding, and fastener insertion. In addition to these are metal deburring, metal cleaning, metal pre-treatment, metal finishing and also tampo pad printing, and silk screen printing.

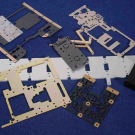

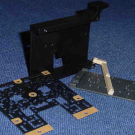

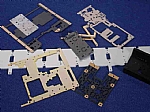

PCB Assembly Tooling

For original equipment manufacturers and contract manufacturers based in the electronics industry, NPI Solutions design as well as manufacture printed circuit board production tooling and assembly tooling.

Our expert design engineers working within this section of NPI Solutions have each accumulated many years of experience. This provides our PCB assembly tooling services with the strength to deliver a solution for every production issue a client may have.

The printed circuit board production tooling and printed circuit board assembly tooling that we manufacture can be divided into four different categories: SMT, conventional soldering, mechanical assembly, and inspection. For more details about the tools we manufacture under each of these areas, please take a look at our website.

PCB Assembly Tooling - Mouldings

Clamping issues? If it’s a printed circuit board clamping problem you have or a component clamping problem, then NPI Solutions have specially designed mouldings to solve these issues.

Our high-quality turnbuckles use the NPI Solutions SCREW LOC system. This ensures that there is no vibration slack during processes. Turnbuckles are manufactured to endure high soldering temperatures.

The same qualities are found in NPI Solutions’ component clamps too. Please note that both of these clamp mouldings are only available unassembled.

We also manufacture moulded surface mount clips, which are designed to cope with high temperatures from reflow processes.

PCB Assembly Tooling - Electronic Assembly - Wave Solder

As part of our range of electronic assembly products, we have several items for wave solder.

Wave solder pallet – Our pallets for wave soldering have many useful features: maximum stability, maximum protection, masking of holes and route slots, addition of clamps, and selective carriers.

Rotational solder pallet – Rotational solder carriers are suitable for both normal production and times when a prototype is needed before the production of fixed carriers.

Flux carrier – Flux carriers identify uneven distributions of flux, operate fast, measure the weight of flux, and understand the performance of this material.

We also have glass solder carriers, adjustable solder carriers, and selective solder carriers. For more details on each of these items, please take a look on our website.

Top hat clamping systems – This item is an enhancement of existing wave solder carriers.

PCB Assembly Tooling - Electronic Assembly - Material Handling

As part of our printed circuit board production and assembly tooling services, NPI Solutions has an array of different electronic assembly capabilities: material handling, miscellaneous tooling, panel assembly, surface mount, and wave solder.

The focus on material handling has resulted in the creation of PCB handling trolley units. As these are designed in-house, our electronic assembly experts can achieve any configuration for PCB handling trollies. We finish these products to RAL specifications to ensure top quality.

NPI Solutions also manufacture rotational fixtures for material handling during electronic assembly. Their design gives the user access to all areas for improved efficiency. For a safer working environment movement has to be controlled using a foot pedal.

PCB Assembly Tooling - Electronic Assembly - Miscellaneous Tooling

NPI Solutions’ miscellaneous tooling for electronic assembly comprises of a wide range of tools.

Brass header weights – Our brass header weights combat component seating problems like toppling during wave or rising up. We have brass header weights for popular pin headers.

Component insertion hand tools – We have hand tools for most popular connectors and pin headers. We even offer bespoke manufacture for component insertion hand tools.

Jig card holder – Jig/card holders significantly reduce the risk of damage to process carriers and bare cards during basic operations by fixing them vertical.

Conformal coating jig – NPI Solutions’ conformal coating jigs allow awkward card shapes to be processed easily and can keep specific areas masked and therefore free of coating.

Pneumatic press – Pneumatic presses are an alternative to hand presses as they are ideal for tricky insertion pressures.

Route support fixtures – These help to maintain the position of cards and scrap areas by providing route support.

Extraction tooling – Extraction tools like a hand-operated screw extraction tool can prevent damaging the pins and component as a whole.

PCB Assembly Tooling - Electronic Assembly - Surface Mount

For electronic assembly during PCB building, NPI Solutions have four useful surface mount products.

Print support plates and pins – These print support devices give support to the print of solder paste on both sides.

Inspection overlays – Inspection overlays can help to avoid costly, incorrectly positioned, or missing components. Our overlays are built especially for unique card configuration.

Print place reflow carrier – Often cards have used an uncommon shape and so surface mount carriers give designs like these both location and support. Choose for underflush clip or offset sprung arms to be fitted to prevent problems with card quality.

Vacuum support blocks – Support blocks improve the position and definition of a card’s images. This is because they provide more stability during the application of paste.

PCB Assembly Tooling - Electronic Assembly - Panel Assembly

We have a number of products for panel assembly.

Hand solder fixtures – Each PCB assembly can encounter a different problem therefore requiring a particular fixture for an issue such as soldering fine details.

Press operation tooling – Avoid damage to your circuit card with press support plates.

Hand-operated press – A hand-operated press avoids damage to components and helps to ensure the right assembly.

Snap shot tooling – These are press assembly tools that fit onto the top and the bottom of the shield where operation is carried out on both of these at the same time.

Press support - We also have press support plates for components with multiple pins.

Details

Info

| Registration Number: | SC220548 |

| VAT Number: | GB774 8718 75 |

| Registered at Companies House: | 22 June, 2001 (22 years and 10 months ago) |

| No of Employees: | 21-50 |

| Annual Turnover: | 2-5m |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Company Certifications

| ISO 9001:2015 - Quality management systems – Requirements |

Products & Services

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Pmr Comms Ltd

- Labels

- Food Display Baskets

- Hydraulic Power Transmission Equipment

- Chalmers Consultancy Ltd

- Van Orten Ltd

- Healthcare Products

- Urmston Boutique Ltd

- Printers Playhouse Ltd

- A.T. Brown & Co. Ltd

- Servo Connectors Ltd

- Spw It Consulting Ltd

- 42 St. Georges Terrace Management Company Ltd

- Water Treatment controllers

- Acoustic Doors

- Postcodes beginning with SO

- Super Surprise Ltd

- Regenerative Thermal Oxidisers

- Epic Heroes Ltd