First Directory is a free resource to bring you more business. We have:

- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Kewell Converters Ltd

Overview

Products

Foam Packaging, Display and Protection.

Engineered Excellence in Foam : Rubber : Plastics

Kewell Converters manufacture to order, and specialise in the fabrication of virtually anything you might require in Foam: Rubber: Plastic with advanced CAD/CAM systems, diverse equipment and quality engineering.

We are known to be able to handle the difficult jobs because of the broad range of converting methods we have available. At the other end of the scale, we can supply sheet foam in any thickness you require from 0.5mm to 300mm at reasonable cost.

Packaging inserts, tool cases, theatrical props, military components, retail displays, medical equipment, impact protection – these are just a few of the markets we serve from our factory near Gatwick.

We keep a large amount of raw materials on site so we can turn jobs around quickly from stock. Check out our guide to delivery times.

Details

Info

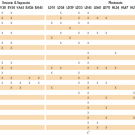

| Registration Number: | 01028194 |

| VAT Number: | GB218 2786 49 |

| Registered at Companies House: | 21 October, 1971 (53 years and 5 months ago) |

| No of Employees: | 11-20 |

| Annual Turnover: | 1-2m |

| Parent Company: | n/a |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Questions

If you've any questions about Kewell Converters Ltd products or services feel free to ask them here.

Additional Information

Brand & Trade Names

- Evazote Foam EVAZOTE® Foam:- Closed cell cross-linked ethylene copolymer foam. EVAZOTE foams are tougher and more resilient than PLASTAZOTE foams and are mainly used in a wide range of sports & leisure and footwear applications. EVAZOTE foam is moulded into knee pads that are durable, and resilient under repeated impact.

- Evazote Foam EVAZOTE ® Foam Closed cell cross-linked ethylene copolymer foam. EVAZOTE foams are tougher and more resilient than PLASTAZOTE foams and are mainly used in a wide range of sports & leisure and footwear applications. EVAZOTE foam is moulded into knee pads that are durable and resilient under repeated impact.

- GalFoam Foam Palziv products are offered in two basic forms: PalFoam™ - material in Blocks. GalFoam™ - material in Rolls. GalFoam and PalFoam employ state of the art production technologies, some of which are proprietary to Palziv. These advanced production techniques yield materials with many important features, including: Possibility of UV exposure on demand. High chemical resistance. Easy processing. Lightweight. A pleasant texture and an attractive appearance. Both products are available in a spectrum of colors. These qualities make GalFoam and PalFoam the materials of choice for use in a wide range of applications, such as: Thermal and acoustic insulation Applications in the building industry Applications in the automotive industry Packaging material Sealing material Children's toys Sports and camping equipment Orthopedic products Shoe industry A variety of other applications A variety of densities and dimensions are available in GalFoam and PalFoam, to meet the specific requirements of different applications.

- Hizote Foam HIZOTE-D LH and EH Foams:- Two new ranges of heavier density cross-linked block foams are now produced by Zotefoams, marketed in the UK under the HIZOTE-D brand. The foams are made using a new and unique manufacturing process that produces an extremely smooth, regular and fine cell structure and consistent density throughout the block. HIZOTE-D LH range is based on polyethylene whereas the HIZOTE-D EH range is manufactured from EVA (ethylene vinyl-acetate copolymer). HIZOTE-D are closed cell, tough, flexible, resilient foams. They exhibit excellent chemical and water resistance and offer good U.V. stability with a wide operating temperature range. They can be easily fabricated using standard techniques. Tests have shown them to be particularly suited to thermoforming. The current HIZOTE-D product range consists of: HIZOTE-D LH 100 Black & LH 170 White HIZOTE-D EH 140 White & EH 170 White The technology used to produce HIZOTE-D foams is able of produce foams over a wide density range. Further densities will be released in due course. Applications for HIZOTE-D foams are known to be for three dimensional gaskets and void fillers in the automotive industry as well as a whole variety of general industrial and leisure uses.

- PalFoam Foam Palziv products are offered in two basic forms: PalFoam™ - material in Blocks. GalFoam™ - material in Rolls. GalFoam and PalFoam employ state of the art production technologies, some of which are proprietary to Palziv. These advanced production techniques yield materials with many important features, including: Possibility of UV exposure on demand. High chemical resistance. Easy processing. Lightweight. A pleasant texture and an attractive appearance. Both products are available in a spectrum of colors. These qualities make GalFoam and PalFoam the materials of choice for use in a wide range of applications, such as: Thermal and acoustic insulation Applications in the building industry Applications in the automotive industry Packaging material Sealing material Children's toys Sports and camping equipment Orthopedic products Shoe industry A variety of other applications A variety of densities and dimensions are available in GalFoam and PalFoam, to meet the specific requirements of different applications.

- Plastazote Foam PLASTAZOTE® Foam:- Closed cell cross-linked polyethylene foam. A wide range of polymer combinations is available to give increased stiffness, improved temperature resistance and improved mouldability. Application areas include packaging, protective padding in contact sports, automotive, health care and building. The inert qualities of PLASTAZOTE have led to its widespread use in healthcare applications.

- Plastazote Foam PLASTAZOTE ® Foam Closed cell cross-linked polyethylene foam. A wide range of polymer combinations is available to give increased stiffness, improved temperature resistance and improved mouldability. Application areas include packaging, protective padding in contact sports, automotive, health care and building. The inert qualities of PLASTAZOTE have led to its widespread use in healthcare applications.

- Propozote Foam PROPOZOTE® Foam:- Closed cell 100% polypropylene foam. PROPOZOTE foam has high temperature resistance and can be recycled. Main application areas are in the automotive and returnable packaging industries. PROPOZOTE is used for returnable medical transit packaging because of its tolerance to sterilisation methods.

- Propozote Foam PROPOZOTE® Foam Closed cell 100% polypropylene foam. PROPOZOTE foam has high temperature resistance and can be recycled. Main application areas are in the automotive and returnable packaging industries. PROPOZOTE is used for returnable medical transit packaging because of its tolerance to sterilisation methods.

- Propozote Foam PROPOZOTE ® Foam Closed cell 100% polypropylene foam. PROPOZOTE foam has high temperature resistance and can be recycled. Main application areas are in the automotive and returnable packaging industries. PROPOZOTE is used for returnable medical transit packaging because of its tolerance to sterilisation methods.

- Rohacell Foam ROHACELL® is produced by thermal expansion of a co-polymer sheet of methacrylic acid and methacrylonitrile. During the foaming process the copolymer sheet is converted to PMI - PolyMethacrylImide. Alcohol is used as a blowing agent, thus ROHACELL® contains no fluorinated carbon hydrates and is halogen free. It has a very homogeneous cell structure and isotropic properties.

- Rohacell HF Foam ROHACELL® HF (= High Frequency) is a closed-cell rigid foam plastic based on PMI (polymethacrylimide) which does not contain any CFCs. The fields of application for ROHACELL® HF are antennas, radomes and X-ray tables. Curing temperature up to 130C (266F). Curing pressure up to 0.35 MPa (50 psi). Sandwich components using ROHACELL® HF as core material can be realized in a single work step (= cocuring). ROHACELL® HF is easy to shape. Thermoformability is another advantage of the core material.

- Rohacell IG Foam ROHACELL® IG (=Industrial Grade) is a closed-cell rigid foam plastic based on PMI (polymethacrylimide) which does not contain any CFCs. ROHACELL® IG-F has the same physical properties like ROHACELL® IG but smaller cell sizes. The fields of application for ROHACELL® IG and IG-F are model building, vehicle construction and shipbuilding, as well as the manufacture of sports articles and X-ray tables.

- Stratocell Foam CelluPlank®, Cellu-Cushion® & Stratocell® Polyethylene Foams Light to medium density foams range from 1.2 PCF up to 9.0 PCF Resilient and cost effecient with superior physical properties for cushioning, insulation and barrier applications High performance cushioning for light, medium and heavy-duty applications using less foam Less foam results in smaller packages, reducing material and shipping costs Can be reused, returned and recycled Available in a variety of colors, including white, black and anti-static grades

- Supazote Foam SUPAZOTE® Foam Super soft, closed cell, cross-linked ethylene copolymer foam. The softest foam in the range, SUPAZOTE is ideal for applications requiring a foam with "soft touch" properties.

- Supazote Foam SUPAZOTE® Foam:- Super soft, closed cell, cross-linked ethylene copolymer foam. The softest foam in the range, SUPAZOTE is ideal for applications requiring a foam with "soft touch" properties.

- Supazote Foam SUPAZOTE ® Foam Super soft, closed cell, cross-linked ethylene copolymer foam. The softest foam in the range, SUPAZOTE is ideal for applications requiring a foam with "soft touch" properties.

- Zotek F Foam ZOTEK® F:- ZOTEK F is a new range of lightweight, closed cell, PVDF (polyvinylidene fluoride) foams based on Kynar® fluoropolymer, a remarkable material that offers a unique balance of properties. Kynar PVDF fluoropolymer has excellent UV, nuclear radiation and ageing resistance, high dielectric strength and outstanding resistance to a wide range of solvents and aggressive chemicals. It is biologically inert, thermally stable across a wide temperature range (to 160°C) and has a very low order of toxicity. It is inherently flame retardant releasing very little heat and only small quantities of smoke during combustion. In ZOTEK F, these properties are combined with light weight, flexural response, buoyancy and thermal and acoustic insulation properties derived from the foaming process. Like their parent resins, ZOTEK F foams will exhibit outstanding durability and longevity. RANGE OF HIGH PERFORMANCE FLUOROPOLYMER FOAMS The new ZOTEK F HT foams offer an operational temperature limit of 160°C, an improvement of +50°C over the current ZOTEK F range. They also offer enhanced chemical and solvent resistance, combined with higher levels of structural rigidity. See our General Flyer CONVERSION All ZOTEK F grades can be manipulated using conventional foam conversion methods, such as die-cutting, water jet cutting, sawing, laminating and welding into continuous rolls. They can be also be thermoformed into complex single component structures providing benefits over multi-layer foam systems, such as weight and cost reduction. APPLICATION ZOTEK F and ZOTEK F HT are used extensively in the civil and military aerospace industry, having excellent insulation properties and meeting the stringent industry flammability requirements. Excellent flammability performance also allows ZOTEK F foams to be used as low closure force seals for electrics/electronics applications where it meets the requirements of UL94 with class V0. Being unaffected by UV radiation, ZOTEK F can be used for high specification building and construction projects with applications ranging from expansion jointing and ridge closures through to tunnel insulation. ZOTEK F has also been shown to meet the EU Single Flaming Source and Single Burning Item tests with a Euroclass B rating. The compliant nature and chemical resistance of ZOTEK F HT make it ideally suited to applications such as high and low closure force seals in chemically harsh environments or high purity are essential. ZOTEK F HT grades are recommended for general use in industrial applications such as chemical engineering, pharmaceutical and medical. The military industry has also shown great interest in ZOTEK F and ZOTEK F HT grades for packaging and thermal insulation purposes. ZOTEK F 38 HT already has NATO codification.

- ZOTEK F Foam ZOTEK ® F ZOTEK F is a new range of lightweight, closed cell, PVDF (polyvinylidene fluoride) foams based on Kynar® fluoropolymer, a remarkable material that offers a unique balance of properties. Kynar PVDF fluoropolymer has excellent UV, nuclear radiation and ageing resistance, high dielectric strength and outstanding resistance to a wide range of solvents and aggressive chemicals. It is biologically inert, thermally stable across a wide temperature range (to 160°C) and has a very low order of toxicity. It is inherently flame retardant releasing very little heat and only small quantities of smoke during combustion. In ZOTEK F, these properties are combined with light weight, flexural response, buoyancy and thermal and acoustic insulation properties derived from the foaming process. Like their parent resins, ZOTEK F foams will exhibit outstanding durability and longevity.

- Zotek N Foam ZOTEK N (development grade):- High Performance Polyamide Foam The company introduced development grade polyamide (nylon) foam ZOTEK N that has been foamed to a density of less than 30 kg/m3. Its closed cell nature and ultra-low density make it unlike any other polyamide foam available. These results have stimulated interest in the automotive, industrial and offshore sectors where polyamide solid materials are widely used and the hydrocarbon and higher temperature performance would offer a superior alternative to other foams currently used. ZOTEK N polyamide foams will offer additional benefits of higher operating temperatures and superior hydrocarbon resistance. They are expected to fabricate into parts in much the same way as the AZOTE polyethylene foams.

- ZOTEK N Foam ZOTEK ® N High Performance Polyamide 6 (Nylon 6) Foam High temperature resistance Excellent chemical resistance High strength and toughness Outstanding resistance to hydrocarbon oils and fuels ZOTEK® N is a new range of lightweight, closed cell, cross linked foams based on polyamide 6 (nylon 6), a tough, strong and durable material with outstanding high temperature tolerance and excellent resistance to a range of chemical, particularly hydrocarbons, such as oils and fuels, alcohols and ketones. In ZOTEK N, these properties are combined with low weight, flexural response, buoyancy and thermal and acoustic insulation properties derived from the foaming process. Like their parent resins, ZOTEK N foams will exhibit outstanding durability and longevity.

- Zotek S Foam ZOTEK S:- Ultra-low Density Silicone Foam (Development grade) Silicone foams are well known for their excellent extreme temperature and exceptional FST (Flame Smoke & toxicity) performance, but existing technology limits their ability to reduce density much below 120 kg/m3 for closed cell materials and 80 kg/m3 for open cell materials. ZOTEK S foams are manufactured with a density of less than 50 kg/m3, 60% lighter than previously possible. This ultra-low density makes ZOTEK S unlike any other silicone foam available. This has already stimulated interest in aviation, aerospace, public transportation and military sectors for sealing and thermal and acoustic insulation applications

- ZOTEK S Foam ZOTEK S Ultra-low Density Silicone Foam (Development grade) Silicone foams are well known for their excellent extreme temperature and exceptional FST (Flame Smoke & toxicity) performance, but existing technology limits their ability to reduce density much below 120 kg/m3 for closed cell materials and 80 kg/m3 for open cell materials. ZOTEK S foams are manufactured with a density of less than 50 kg/m3, 60% lighter than previously possible. This ultra-low density makes ZOTEK S unlike any other silicone foam available. This has already stimulated interest in aviation, aerospace, public transportation and military sectors for sealing and thermal and acoustic insulation applications.

Company Certifications

| ISO/TS 9002:2016 - Quality management systems – Guidelines for the application of ISO 9001:2015 |

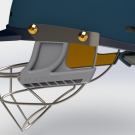

Gallery

Financial Information

To view more detailed financial information for this company click here.

Popular Links

- Hair Spa Ltd

- DC/AC Linear Power Supply

- MARK AITCHISON & SON LTD

- Advance Tapes International Ltd

- Nitrogen Analysis Equipment

- Autolocators Ltd

- Elfino Ltd

- Bpo Ltd

- Orange Pixel Ltd

- FALCON LANE CONSULTING Ltd

- Companies beginning with W

- Live Marketing Ltd

- INTEGRATED BIOMEDICAL SOLUTIONS Ltd

- VAEA LONDON LTD

- Office Furniture

- Steel Burrs

- ARM Ltd

- Ringstead Carshalton Management Company Ltd

- TIG (Tungsten Inert Gas) Stainless Steel Welding