- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

GDS Technologies Ltd

Overview

- Mr Bernard Quirk - Commercial & Contracts Manager

- Miss Julie Mitchell - Field Service Manager

- Miss Jody Kidd - Sales Administrator

- Mr Ian Hutchinson - Purchasing Manager

- Mr John Hicks - Quality Manager

- Mr Zubair Haroon - Technical Manager

- UTLEY, Angela Lydia - Director

Products

GDS Technologies Ltd specialises in gas detection products and services for commercial, retail and industrial markets. We provide advanced equipment for use in all types of environments. Our equipment is either standard or badged to OEM, resellers and end users across the world. We also provide customized design solutions upon individual request. Our products are manufactured by highly skilled engineers at our Leeds site. Our team works to strict quality control procedures to ensure the highest quality standards are met at all times. We are committed to providing our customers with first-rate products with a first-rate service.

We are renowned for the quality of our products and the reliability of our products and services both before and after sales. It is important to us that our customers receive a full level of care in order to get the very best out of their GDS products and services. Our gas sensors are widely used for personnel protection against toxic, flammable, and asphyxiate gases. Alongside our range of gas sensors we also supply a range of alarm indicator panels as well as various other accessories to compliment the range. Alongside our range of products and services, we also provide customer in-house product training for up to four delegates. This is undertaken at our training facilities in Garforth.

We also provide training programmes for up to six delegates on customer sites. Please visit our website for technical data, product specifications including images, downloads, news of new products and more.

If you require any further information or assistant please don't hesitate to contact us.

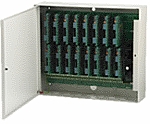

Combi Fixed System

The Combi addressable/direct gas monitoring system is designed to be suitable for use in all kinds of environments ranging from small commercial premises through to large industrial types. The Combi is typically used for locations such as public buildings, car parks, tunnels, breweries, boiler plant rooms, water treatment works, H&V control, manufacturing, process plants, horticulture, hotels, and office. It features up to 64 addressable sensors per controller and can form a network system of up to 16 controllers. For further details please visit our website.

Gas Net Fixed System

The Gas Net monitoring system offers up to 32 addressable sensors, and can form a network of three core or single four core sensors. Larger networks can easily be created using multiple Gas Nets housed in a 19inch rack based system. The Gas Net displays operating conditions on its display. It has 16 user selectable alarm relays and a 32 way replay panel as an option. The Gas Net sensor is simple and straightforward to install and is supplied pre-calibrated ready for use.

Flow Sample System GDS 301

This model is designed for the monitoring of gas levels in particular areas where conventional gas sensors are not placed in a practical position either by equipment security, cable routing, access for detector head installation/maintenance, or harsh environments. The GDS 301 can also be used as a cost effective monitoring system for hazardous areas such as tunnels, marine applications, underground/high level voids, process control, brewing, horticulture, and livestock husbandry. The GDS 301 features continuous monitoring of flammable, oxygen or toxic gases, has two alarm levels and relays, 4-20mA analogue output, line blockage and pump fail monitor and a delay to alarm

option.

Flow Sample System GDS 302

The GDS 302 is a single point short line sample unit. It features two alarm levels, alarm relay outputs, delay to alarm options, comprehensive fault monitoring, line blockage monitoring, pump failure monitor and an optional remote pumped sensor unit. The GDS 302 operates by continuously extracting a gas sample from the fixed position in which it is placed. Gas level readouts are provided by the central unit for monitoring purposes.

Flow Sample System GDS 305

We also supply the GDS 305 sequential gas sampling system. This model has 1-48 sample points and can monitor up to four gases. The GDS 305 operates by sequentially extracting gas samples for a timed period by a central control unit via fixed sample lines. Gas levels readouts are provided by the central unit for monitoring purposes. The central unit has two alarm trip points per line and provides a range of signal outputs for annunciator and control functions. Please visit our website for detailed product specifications.

Flow Sample System GDS 306

The GDS 306 is a 1-20 way sequential gas sampling system. It features two sensor types, 4 line alpha/numeric display, a selectable sample line sequence, event logging/ Modbus/ RS232/ RS485, variable sample time for optimum cycle time, and optional split system operation, as well as line blockage blow back, hazardous area operation, remote repeater panel, enclosure internal gas monitoring with automatic system shutdown, and auto flood cut-off. This system is designed for areas where the position of conventional gas monitoring systems may not be effective such as in various hazardous areas.

Customised Equipment Labels

As part of our range of services we are pleased to provide our customers with customised company labelling for use on our range of products. These are charged at cost price and are held in our stock until levels deplete to a minimum re-order level. We then contact the customer to re-order. Labels can be created by customers and sent to our design team who will amend and process labels.

Please visit our website for details of artwork costings.

Test Equipment

Our Sensor Check Gas Kit features a calibration kit - regulator with a fixed flow 1 litre/minute), tube (3M length), test gas applicator cap and test gas bung plus carry case. The gas list includes flammable gases (test gas cylinder methane, propane, butane, pentane, acetylene, hydrogen), refrigerant gases (test gas cylinder R22, R134a, R152a), and toxic gases (carbon monoxide, carbon dioxide, hydrogen sulphide, sulpher dioxide, ammonia, nitric oxide, nitrogen dioxide, ethylene oxide, hydrogen chloride, chlorine), and test gas cylinder nitrogen and oxygen in N2.

Status I Indicator Panel

This model provides a wide range of warning and alarm applications with a combined audible and ‘text selectable’ illuminated window indication. The audible alarm can be silences at any time while the visual alarm continues to flash until the alarm condition has been cleared. The Status I Indicator Panel features safe, caution, gas and fault indicators. It has a maximum power per signal input 1 watt, protection IP65, a mutable 98 db at 30cm sounder, permanent sounder mute-option, remote mute terminals and more.

Status II Indicator Panel

The Status II Indicator Panel is a remote alarm unit that hosts a range of warning and alarm applications for effective use. The audible sounder is at 98 db at 30cm and can be muted at any time. If the sounder isn't muted it automatically mutes itself by default after a five minute period of continuous operation and the visual alarm window will stay illuminated until the alarm has been cleared. The Status II Indicator Panel is easy to install and is protected to IP65 standards.

Field Service

We provide a contract maintenance and repair service to ensure that you get the very best from your products. All products, no matter how high the quality, will need servicing or repairs at some stage and for equipment such as ours it is important that systems are maintained regularly to enable safe, effective use. Our contract service/ maintenance ensures vital gas detection systems are working correctly, number of faults and duration times are minimised, high levels of performance are preserved, upgrading of systems for the compliance of legislation and discount from standard non-contract service charges. We also carry out non-contract repairs as well as repairs to systems that have not been supplied by us so that you could still benefit from the experience of our team.

Auxiliary Equipment

We supply a range of auxiliary equipment to complement our range of products. Items include battery backups, auxiliary power supplies, beacon amber 24v IP65, combined beacon sounder 24v IP65, relay panel 48 way, relay panel 24 way, battery 705 backup, catalytic to 4-20mA converter 1-16 way, relay panel 32 way, fixed sensor test gas injection point, duct flow sample unit, auto drain unit, duct mount sensor kit, blow back auto drain units, and more. For full details of our complete range of products, please visit our website, or contact us at GDS Technologies Ltd.

Flammable Gas Detectors

GDS Technologies Ltd supplies flammable gas detectors for both hazardous and safe area applications. On our website you’ll find a whole series of highly reliable systems such as our best-selling F1 Gas Sensor (right), a compact and cost-effective unit that provides accurate measurements at fast speeds. The F1 has been designed to operate in a full range of environments, from commercial premises to heavy industrial areas. A range of accessories are available that enable the F1 Gas Sensor to be used in a diverse range of applications, including HVAC ducting, flowline systems or freestanding open-air applications. Find out more about the F1 and our other flammable gas detectors by visiting the GDS Technologies website.

Toxic / Oxygen Gas Detectors

We also offer a range of devices for the detection of toxic gases and oxygen. These cover numerous hazardous and safe area applications. The F6 Gas Sensor (right) is one the most popular in the series, and is most commonly used in car parks, boiler/plant rooms and commercial/public buildings. Just like the F1 Flammable Gas Detector (above), the F6 is a compact, cost-effective unit that gives fast, accurate results. Housed in a stainless steel enclosure, it is certified as flameproof in accordance with IECEx/ATEX regulations. You can find out more about the F6 and our other toxic/oxygen gas detectors by visiting the GDS Technologies website.

20 Way Status Alarm 3

The 20 way status alarm is a highly reliable remote alarm mimic system that extends the audible and visual warning information to any satellite area beyond the range of the main controller. When an alarm input circuit receives a signal, the appropriate alarm LED will flash with the sounder and alarm relays will be turned on. The sounder can be muted by pressing the reset switch. Once the alarm signal has cleared, the alarm LED can be turned off using the reset switch. Full specifications can be found on the GDS Technologies website.

Snoop Repeater Panel

The GAS NET Snoop Box is a high quality repeater panel system that can be attached to the network at any point using a 4-core cable. It offers four analogue 4~20mA outputs, each of which may be driven by any number of the 32 sensors providing a peak reading output. For full details and specifications, please visit our website. If you have any further questions regarding our Snoop Repeater Panels, do not hesitate to get in touch. We’re always happy to receive your call.

Single Sensor Gas Detection System GDS 100

The GDS100 is a single point gas alarm that has been designed for reliable, economic monitoring of gas levels in a wide range of environments, from commercial premises through to heavy industrial applications that require hazardous area sensing. Typical monitoring locations include public buildings, swimming pools, boiler plant rooms, water treatment works and manufacturing plants. The GDS100 can be wall or panel mounted, and may have either a remote or internal sensor. A digital display allows the user to easily configure settings.

1-4 Sensor Gas Detection System GDS 404

The GDS404 is a 1-4 channel gas alarm that provides a fast, effective response to the detection of gas hazards in a range of environments. Typical locations include public buildings, swimming pools, boiler plant rooms, water treatment works, and manufacturing and processing plants. The GDS404 benefits from a versatile system configuration, two alarm stages, delayed alarm options and internal battery backup (optional). Full technical data for the GDS404 can be found on the GDS Technologies website.

Details

Info

| Registration Number: | 03529380 |

| VAT Number: | GB481 8400 44 |

| Registered at Companies House: | 17 March, 1998 (26 years and 1 month ago) |

| No of Employees: | 21-50 |

| Annual Turnover: | 1-2m |

| Importers: | |

| Exporters: | |

| Company Type: |

|

| UK Branches: | Leeds |

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Company Relationships

Company Certifications

| ISO 9001:2015 - Quality management systems – Requirements |

| ISO 14001:2015 - Environmental management systems – Requirements with guidance for use |

Products & Services

Gallery

Financial Information

To view more detailed financial information for this company click here.

- One Kensington Church Street Ltd

- Brian Hyde Ltd

- Double Sided Adhesive Tape

- J F European Services Ltd

- Alnoor Properties Ltd

- Gap 66 Ltd

- Valkyrie It Ltd

- R & W Motors Ltd

- Orseal Ltd

- Bespoke Kitchens

- BRISTOL

- Programmable Temperature Control Systems

- Scaffolding Erection Contractors

- Antique Church Furnishings Ltd

- Talbott's Biomass Energy Systems Ltd

- Balacs Ltd

- Springer-Miller International LLC

- City Island Management Ltd

- INNOVA HEALTHCARE UK LTD