- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Engineering Dynamics (Southern) Ltd

Overview

- Mr David Weeks - Managing Director

- HARVEY, Joshua Thomas - Director

Products

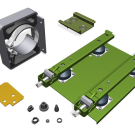

Engineering Dynamics Ltd is a specialist designer and manufacturer of standard and bespoke vibration isolation and rubber moulding products. We're a small, privately owned company with over three decades of experience in the field, and we pride ourselves on a customer-focussed approach. We provide clients with technical advice and design recommendations for their applications, consulting at all stages of the development process for an optimised solution.

As well as developing brand new, innovative designs, Engineering Dynamics provides a cost-effective option in the form of standard products for those customers who do not require application-specific components. Our standard ranges of vibration isolation mounts are available in a range of materials. At our development facility we have our very own in-house design team using the very latest 3D CAD, FEA and Modal Analysis technologies. We also have an on-site rubber moulding shop, vibration testing lab, and a tooling shop. Our vibration simulation machines, which we use for component testing, are available to third parties for hire.

We have a range of equipment that covers sinusoidal vibration testing, random vibration testing, shock and bump simulation, and standard vibration testing. We've designed and supplied vibration isolation components for a range of industries, including defence, where our products have been used in Harrier, Tornado and Eurofighter Typhoon jets, Challenger 2 Tanks, Lynx Helicopters, Rapier Missile Systems and various light artillery and armoured vehicles. Only components of the very highest quality are used in such applications, and only a company as skilled and experienced as Engineering Dynamics can provide them. To find out more about Engineering Dynamics, its services and products, please head to our website, or get in touch directly with our expert team.

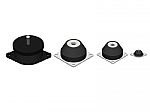

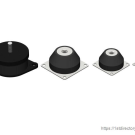

Anti-Vibration Mounts - Visit our website

We design and manufacture top quality anti-vibration mounts, including base, bush, plate, shock and surface mounts. Our customers depend on us to provide the very best products and our technical experts do everything that is needed to make sure each customer gets the right solution for their specific equipment and requirements. To that end, our experts are always more than happy to help with sound and reliable advice, liaising with your design team as needed. To further ensure your specifications are fully met, we can produce a bespoke anti-vibration mount to meet all your specific needs.

Rubber Mouldings - Visit our website

As well as anti-vibration mounts, we design and manufacture rubber mouldings, and these two products form a core part of our service. We have a knowledgeable team of technical experts who are available to give our customers the benefit of their experience and expertise, helping you to identify the best solution for your specific requirements. We work diligently to achieve our prime aim, which is to provide the very best products and service to all our customers, who can be assured that Engineering Dynamics can be relied on to offer sound advice when needed and deliver superior products at all times.

Vibration Testing - Visit our website

We are pleased to offer vibration testing facilities for Sinusoidal Vibration, Random Vibration, Sine-on-Random and Shock Testing. Whether you are looking to assess and develop mechanical sub-assemblies or complete equipment, we offer the capacity you require. We employ a Ling 900 Combo V826LS coupled to a Ling DPA 16 amplifier, along with a Bruel & Kjaer Laser USB, which is used to control the vibration test. We calibrate all our equipment on annual basis, in line with our ISO9001 certification. We invite customers to stay and watch their test, if desired. The vibration test facility can also be hired out on a half day basis, as needed. Our superior testing facilities, coupled with our capability to offer workshop modifications or repair if required, adds up to what is at least one of the top, possibly the best, cost-effective vibration testing facilities in the UK.

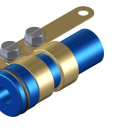

Fighting Vehicle Connectors - Visit our website

We have been supplying direct to the MOD and many other harness manufacturers since 1996, so we have the experience and expertise needed to produce high quality and reliable fighting vehicle (FV) connectors. We offer the full range of fighting vehicle single pole quick release connectors. You can see the complete range on our website, along with comprehensive data sheets on each product.

Aerospace Products - Visit our website

We are pleased to offer a good range of aerospace products, all complying with appropriate and relevant Eurofighter Standards. Products include mating/unmating devices, an inserter extractor, a range of rear hold down pins, a front hold down pin and moulding in various sizes. All products in the range maintain our high standards of quality, reliability and durability. Visit our web site where you can see more information about our selection of aerospace products.

Details

Info

| Registration Number: | 01517290 |

| VAT Number: | n/a |

| Registered at Companies House: | 15 September, 1980 (43 years and 7 months ago) |

| No of Employees: | 1-10 |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Company Certifications

| ISO 9001:2015 - Quality management systems – Requirements |

Products & Services

- Anti Vibration Mounts

- Antivibration Bearings

- Anti-vibration Couplings

- Antivibration Equipment

- Anti-vibration Machine Mounts

- Anti-vibration Mountings

- Anti-vibration Pads

- Antivibration Specialist

- Antivibration Specialists

- Bump Testing

- HVAC Anti-vibration Mountings

- Isolators Vibration & Shock

- Rubber Moulding

- Shock Control

- Vibration & Shock Isolators

- Vibration Attenuating Couplings

- Vibration Control Materials

- Vibration Control Mountings

- Vibration Control Mountings

- Vibration Control Services

- Vibration Dampening Machine Mounts

- Vibration Equipment

- Vibration Isolation

- Vibration Isolation

- Vibration Isolation Components

- Vibration Testing

- Vibration Testing

Gallery

Financial Information

To view more detailed financial information for this company click here.

- "london Carpenter Uk" Ltd

- Rg London Properties Ltd

- IMPERIAL TOY UK Ltd

- IFM Electronic Ltd

- Pigment Concentrates

- Egg Packaging

- Metal Testing Potentiostats

- Edgar Lawson Ltd

- BLACKFRIARSBAR LTD

- Eastern Spice (Wythenshawe) Ltd

- Advantage Accountancy Tax & Outsourcing Ltd

- Titanium

- Libertas Trading Ltd

- Waterproof Computers

- Mirage Energy Ltd

- Mudfords Ltd

- Postcodes beginning with CF

- Confide Counselling Ltd

- Salus Vita (UK) Ltd