- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

dalau Ltd

Overview

Products

With subsidiaries in New Hampshire, USA and in Türkheim, Germany, exporting to 35 countries around the globe, dalau™ has come far since its establishment as a family business in and has grown to become the largest Polytetrafluoroethylene (PTFE) processor in the UK.

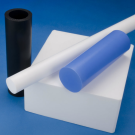

Only using the finest quality virgin PTFE, dalau™ specialises in producing high quality extruded rod, moulded rod and tube, skived films and sheets and machine components, and, can also offer these products in a wide range of filled grades and colours. Extensively used across a diverse range of industries and applications, the company’s products have been specified for some of the world’s most prestigious projects. With products manufactured under the dalcon™ trademark, so distinguishing our high quality PTFE products from the competitors in the field, dalau™ is recognised for their innovative approach to product design and development as well as for high standards of quality control. Significant to the growth and development of dalau™ over the years is a great emphasis on total quality performance, based on fully computerised statistical process control systems (SPC) combined with an excellent standard of customer service. Visit the main website to view videos, accreditations, to download brochures relating to the company and to learn more about their products and services.

Extruded & Moulded

To ensure a high standard of uniform density levels and physical properties our PTFE products are produced under the dalcon™ name. We specialise in being able to offer a wide variety of high quality extruded rod and hold large stocks of ground and unground rod from 4mm to 100mm in 1m, 2m and 3m lengths. Our PTFE rods are of an exceptional quality and are produced in our own in-house designed and built extrusion system. We also offer precision grinding, for customer who require uniformed tolerances rod for high speed machining. Visit our website to learn more about our products and services.

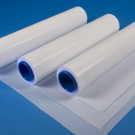

Films & Sheets

Through continual investment and innovation, we can produce PTFE films of the tightest tolerance and of exceptional quality with high physical properties and a skive-free surface finish; allowing us to meet the exact requirements of the circuit board and semiconductor industries. Our high precision CNC skiving capabilities can produce 0.025mm by 1500mm wide film; one of the finest tolerance films available on the market. Our superior PTFE dalcon™ skived film is produced in a fully enclosed class 10,000 clean room with inline static eliminators and finite tension control. This allows us to produce a superior finished product. We also produce standard high quality films and more!Machined Components

To exact and stringent technical specifications, dalau™ specialises in the precision machining of plastic components in all engineering plastics to the electronic, medical and aerospace industries and can turn PTFE, PA, PE, PEEK, ETFE and numerous other engineering plastics for prototyping, small batches and large volume runs. Take a look at our website to see photographic examples of our machining capabilities along with the various machine models we use. Here you will also find more technical specifications and further information on the way we work. If you have any questions about our machined components or services then please get in touch.

5-Axis Machining

With machining capabilities ranging from one-off prototype components to large batch sizes, our continual investment in the latest 5-axis machines allow for the production of even larger and more complex parts - see the example on our website of the ‘5-axis machining of the human head’; made possible by our range of state-of-the-art DMG high precision 5-axis machining centres which are designed for 5-sided and simultaneous machining. Housed in a fully-enclosed, temperature-controlled room, we can offer unprecedented 5-axis flexibility for one-hit machining. Contact us for more information on our 5-axis machining capabilities and let’s see what we can do for you!Micro Machining

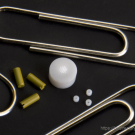

Typically used components in the aerospace, electronics, medical and telecommunications industries, dalau™ are specialists in precision micro components, producing over 100 million PTFE dalcon™ and other plastic machined components a year! The first to be installed in the UK, the Micro 8 turning centre from Tornos is capable of machining extremely small parts to very tight tolerances - a capability which has been perfected by Tornos over decades of manufacture for the medical and watch-making industries. Quality is a key focus at dalau™ and the company has developed its own SPC system as part of its TQM system which is linked to the CNC control of the Tornos machines.

Quality Control

As heavy investors in effective quality management and monitoring processes that can be relied upon when machining high quality products, dalau™ has a paramount commitment to quality. Every part of our production process is recorded on our proprietary statistical process control system (SPC) - something at the heart of our quality regime. This allows complex computer models to monitor and maintain high production standards ensuring a consistent high quality across every finished product. With results kept on our computer system for seven years, samples are analysed at all stages of the production process. These results allow total traceability on every product.Compounds & Colours

At dalau™ we offer a huge variety of colours and fillers including glass, carbon, graphite, coke, anti-static, bronze, MoS2 and special blends to customer specifications. We have custom-designed blending facilities where PTFE dalcon™ based compounds and colours are blended in a clean and climate-controlled environment. All of our compounds offer exceptional characteristics in meeting extreme customer application requirements including chemical resistance, covering a wide working range of temperatures, low coefficient of friction to solid, extreme dielectric properties and more! At dalau™ we take pride in providing customers with exactly what they need. Talk to us about your specific compound and colour requirements today!

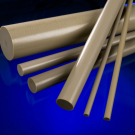

PEEK (PolyEtherEther Ketone)

One of the few plastics compatible with ultra-high vacuum applications and considered an advanced biomaterial used in medical implants, PEEK, because of its robustness, is used to fabricate items used in a range of demanding applications including bearings, cable insulation, compressor plate valves, HPLC columns, piston parts and pumps. It is used extensively in the aerospace, automotive and chemical process industries.It’s a semicrystalline thermoplastic with excellent mechanical and chemical resistance properties which are retained to high temperatures. It is highly resistant to thermal degradation as well as attack from both organic and aqueous environments. Visit our website to download the ‘Typical Properties’ PDF.

PCTFE (Polychlorotrifluoroethylene)

Typical applications for PCTFE are as a moisture barrier for pharmaceutical blister packaging, a water vapour barrier for protecting phosphor coatings in electroluminescent lamps, protection in liquid crystal displays (LCD) which are sensitive to moisture and protection for sensitive electrical components and insulation for wires/cables. The material has many properties similar to that of other fluoropolymers such as PTFE, FEP and PFA, the main difference being a mechanical superiority in rigidity (doesn't deform easily) and it also has very low gas permeability. Our website provides a range of technical specifications for this material relating to mechanical, thermal, electrical and other properties.

PVDF (PolyVinyliDene Fluoride)

PVDF is typically used in filtration and separation equipment including filters, membranes and housings. It’s also used in transport systems, tactile sensor arrays, strain gauges, insulation on some kinds of electrical wires and circuit board & printed circuit board rework is PVDF insulated. It can also be used in lightweight audio transducers and artificial membranes. It’s generally used in applications requiring high purity, strength and resistance to solvents, acids, bases and heat. Our website provides a range of technical specifications for this material relating to mechanical, thermal, electrical and other properties. You can also download PDFs relating to this material.PTFE (Polytetrafluoroethylene) dalcon™

PTFE is commonly used in bearings, skived film, rotors and clam shells, tank linings, wafer carrier, valves, tubes & linings, and filters. The chemical resistance properties of PTFE are so broad that its use is not limited to only a few chemicals. As a result these materials are generally accepted for use in a wide range of industries and commercial applications. It also qualifies for ultra-pure applications such as using deionized water in a semiconductor and biological/pharmaceutical industries because of its lack of additives and extreme chemical inertness. Download the ‘PTFE Chemical Qualities’ PDF on our website to learn more.

Aerospace

With AS 9100 Rev C approval to manufacture high quality parts for the defence and Aerospace industries, dalau™ has manufactured precision machined components for the Eurofighter, the new Airbus 380 and Formula One racing cars! We use a DMG DMU50 for multi-axis machining. Visit our website to learn more about our contribution to the Aerospace industry. You can also visit us at the annual Aero Engineering Show at the NEC, Birmingham UK. If you have any questions about how we may be able to help you with your particular application or wish to know more about the way we work then please contact us.Electronics

We make over 100 million PTFE dalcon™ and other plastic components a year using the latest technology in micro machining. Over the years we've served a huge range of electronics applications with machined components, micro machined components, high voltage insulators and the Tornos Deco 2000 - for more information on the Tornos CNC machine please visit our website where you will find a link to their website. The micro machining or 5-axis machining of components can be one-off prototypes or, for customers in the BNC connector, multi-pin, high frequency insulator industries, batch quantities of 250,000. Call us with you requirements today!

Semiconductor

At dalau™ we have Computer Aided Design (CAD) and advanced Computer Numerically Controlled (CNC) machining capabilities so we can produce custom high and low profile wafer, mask and substrate carriers to precise specifications. Available in PTFE dalcon™, PTFM, PCTFE and static dissipative compounds, cassettes can be machined a single piece construction; not fastened together by any screws or pins. See our website for photograph examples of a low profile wafer carrier and PTFE chamber. Our state-of-the-art 5-axis machines produce some of the largest custom-made components required by the semiconductor industry. We mould all our stock shapes in a temperature controlled, pressurised clean room.Chemical

Using state-of-the-art 5-axis machines to produce premium quality, high performance machined components, dalau™ can machine highly complex solid PTFE dalcon™ chemical pumps to customer specifications for high purity applications. Take a look at our website for photographic examples of our machined components and the DMG BETA 1250C. You can also find more information on the DMG BETA 1250C by clicking on link available on the same page. If you’d like to know more about how dalau™ can help you with machined components in your particular application or industry then please feel free to contact us and we’ll be more than happy to help.

Engineering

dalau™ is very pleased to have been awarded two highly prestigious contracts for BP Floating Oil Rig Angola and also Sydney Opera House because of our engineering industry capabilities. You can view detailed information on the work we carried out on these two amazing projects by visiting our website. Our contribution to the engineering industry is diverse; we can manufacture bearing pads, slide plates and friction brakes that can be etched and bonded onto steel, cast-iron or other plastics. We use a DMG DMU50 for various components. You can find out more about this machine by visiting our website and clicking onto the link.Details

Info

| Registration Number: | 00609539 |

| VAT Number: | n/a |

| Registered at Companies House: | 12 August, 1958 (65 years and 8 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: |

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Products & Services

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Contamination Measuring Systems

- Tyrus Wings Ltd

- A & S Brown Plant Hire Ltd

- Fire Protection Coatings

- Switch 2 Renewable

- Companies beginning with S

- Actuated Valves

- Waterproof Electronic Components

- BERRY'S BAKES LTD

- Granulation Compactors

- Coolbay Ltd

- A.B. Quantity Surveying Ltd

- Sounds Simple Ltd

- Ix Global Ltd

- EXCELLENCE BUILDERS LTD

- Illuminated Signs

- Bulk Liquids Handling Equipment

- MIZAR CONSULTING LTD

- Aspire Management Consultancy Ltd