- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Bracebridge Engineering Ltd

Overview

- Mr Keith Street - General Manager

- PARKER, Luke Andrew - Director

Products

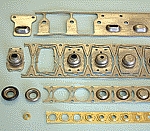

Bracebridge Engineering Ltd specialises in the manufacture of high quality pressings and production tooling. For over 25 years, we have been pressing metal components for a range of industrial sectors in the UK and throughout Europe, all from our state-of-the-art facility in Birmingham. Over the last quarter-century, we've built a solid reputation in the sector based on our commitment to quality and service. We work with our customers at every step of the process, from the design phase through to development, prototyping and volume production. Bracebridge Engineering has experience across a range of industrial sectors, including aerospace and automotive, and we've also worked in some highly specialised niche industries. Our experience and expertise means we can offer expert advice on the best manufacturing methods for the cost-effective production of metal pressings, pressed components and sub-assemblies. We employ an expert team of dedicated design staff who are focussed on finding the perfect solution for your production requirements. To ensure an exceptional product standard, we adhere to rigorous quality control procedures - with Bracebridge Engineering, you can expect precision pressings of the very highest quality. So for bespoke presswork and metalwork pressings, make no compromises and choose Bracebridge Engineering. Give us a call today to discuss your presswork requirements.

Precision Presswork

Precision and quality is the all important factor in the presswork manufacturing industry. At Bracebridge Engineering, we have the skills, experience and manufacturing capabilities to produce precision presswork to the very highest quality. This is achieved through ongoing investment into state-of-the-art manufacturing facilities and the implementation of ISO-accredited quality control procedures. Our engineers work with a variety of ferrous and non-ferrous metals, including copper, brass, mild steel, aluminium and cast iron. We have worked across a range of demanding sectors that require nothing less than the best, including the aerospace and automotive industries. To find out more about our presswork capabilities, follow the link to our website or get in touch with our experts.

Tooling Solutions

Quality components can only be manufactured with well-designed and well-maintained tooling. At Bracebridge Engineering, we offer tooling solutions such as:

- Technical support in the design phase

- Single operation tooling, including piercing, blanking and forming

- Deep drawing with air cushion

- Multi-stage coil-fed progression tooling

- Transfer press tooling

- Special purpose tooling

- Secondary operation and assembly tooling

We have been making presswork tools for over 25 years, so you can count on us for quality and accuracy. For precision results, presswork tooling needs to be well-maintained. With specialised welding technologies at our disposal, we're able to keep your tools in top condition.

Welding

As well as toolmaking and metalwork pressing, Bracebridge Engineering offers a number of other metal fabrication services. One of these is welding. Ongoing investment into the very latest welding technologies enables us to take on a range of welding projects, including spot welding and seam welding. Our welding engineers have a wealth of experience working across a range of industrial sectors, including aerospace, automotive and marine. If you would like to find out about our welding capacity, please give us a call. We'll discuss all projects, no matter how simple or complex, so do not hesitate to get in touch.

Assembly

We understand that different clients have different manufacturing needs. Some require unassembled components, while others need their products in the assembled condition or as kits with other parts. At Bracebridge Engineering, we can work to the most convenient method of supply, whether that's a Kanban system or holding safety stocks in completed form. Whatever your manufacturing needs, Bracebridge Engineering can provide the solutions. Get in touch to find out more about our product assembly services.

Tube Sawing

Bracebridge Engineering has a range of metalwork fabrication facilities at its disposal, including several high quality Adige automatic tube saws. These allow us to cut metal tubes exactly to your specifications, up to 75 mm dia. To find out more about this service, please get in touch our experts by telephone.

Finishing

Metal finishing is an extremely important manufacturing process. Without it, metal components would quickly corrode and wear out. Processes like anodising, electro-plating, mechanical plating, hardening and powder coating improve corrosion resistance, wear resistance, tarnish resistance, torque tolerance, reflectivity and appearance. Certain processes can also enhance electrical properties such as conductivity and resistance. Others are used to form and shape components, and even enhance the components' ability to be bonded with adhesives. Simpler metal finishing processes include painting and ceramic coating. To find out more about our metalwork finishing capabilities, visit the Bracebridge Engineering website or get in touch directly.

Supply Directory

Bracebridge Engineering has put together a comprehensive directory of ferrous and non-ferrous metal suppliers, dealers, importers and exporters. On our website you’ll find further information regarding these suppliers and how to get in touch. A website link is included. All of the suppliers listed on our website have been approved by us for quality and service.If you would like to find out more about who we are and what we do, please visit the Bracebridge Engineering website, or simply get in touch via telephone. We're always happy to receive your call.

Metals

Bracebridge engineers are able to work with a range of ferrous and non-ferrous materials, including mild steel, high tensile steel, stainless steel, carbon steels, aluminium, copper, brass, tin and various aluminium alloys. These are just some of the metals regularly processed at our manufacturing plant. You can find out more about the properties and uses of each material by visiting the Bracebridge Engineering website.

Details

Info

| Registration Number: | 01299727 |

| VAT Number: | n/a |

| Registered at Companies House: | 22 February, 1977 (47 years and 4 months ago) |

| No of Employees: | 11-20 |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Company Certifications

| ISO 9001:2015 - Quality management systems – Requirements |

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Aaa Accident Claims Management Ltd

- Formby Play Sports Ltd

- Busbars

- Gibbs & Dandy

- Postcodes beginning with BR

- Surrey Administration Services Ltd

- Surface Hardening

- Epos Trading Ltd

- Picture Restorers

- Plumbonline.Net Ltd

- Frontline Training Associates Ltd

- Telephone Service Providers

- Cbg Procurement Ltd

- S I C - Solid International Consultant Ltd

- Dry Ice Blasting Systems

- Gongoozler Consulting Ltd

- Westwell Prime Ltd

- Itop Ltd

- Hazardous Area Data Terminals