- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Durham Foundry (Sheffield) Ltd

Overview

- Mr Mike Naylor - Man. Dir.

- NAYLOR, Joanne Maria - Director

- NAYLOR, Michael Christopher - Director

- NAYLOR, Richard John, Dr - Director

Products

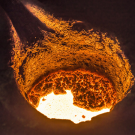

Established over 100

years ago, Durham Foundry is a Sheffield based manufacturer of iron

castings, particularly for the engineering, architectural and

decorative markets. Despite our long history, we operate from a

modern manufacturing facility, and use a skilled workforce to produce

a range of grey, ductile and alloy iron castings. Our jobbing foundry

service produces cast iron of the following types; grey,

ductile/spheroidal graphite, austentic/ni resist, compacted

(vermicular) graphite, ADI/ausferritic spheroidal graphite, wear

resistant/ni hard/high chrome, and special irons made to

specification. These castings are supplied worldwide in many sectors,

for anyone from industrial users and equipment manufacturers to

decorative sectors.

At Durham Foundry we

have no minimum weight and can produce castings of most shapes and

sizes, with the usual maximum weight being approximately 1 tonne. We

can also give quotes on items up to 30 tonnes. Runs can range from 1

off to 1000 off, depending on the size and shape, and smaller items

can have runs of 5000 and above.

Our other services

include providing continuous cast iron bars in a range of round or

rectangular sections, in grey iron or ductile iron. We can also

supply round bar produced from the above materials “as cast” or

proof machined. Our long association with a variety of engineering

companies allows us to give good quotes on fully machined castings if

required.

Cast Iron & Iron Castings

During the industrial revolution, improved methods of production and knowledge of the metallurgy resulted in grey cast iron becoming a reliable and versatile material that subsequently experienced a boom in usage. The varied uses of cast iron continue to this day thanks to its ability to be cast in complicated shapes at a lower cost than other materials.When allowed to cool normally, molten cast iron develops flakes of graphite, and as such, is sometimes know as flake graphite iron. These flakes are microscopic but form stress points in the iron. However, flake graphite cast iron is effective under compressive load, as these stress points are not particularly harmful.

Iron Castings

For more than 400 years, iron castings have been the solution for architectural and engineering problems, with applications in the manufacture of cannon barrels as early as the 16th century. Iron became significantly more useful in the industrial revolution due to improved production methods that allowed it to be used in bridge, locomotive and ship construction.Iron castings of the type Durham Foundry manufacture were traditionally made using sand moulds, the earliest type being Greensand. This type of mould was made from silica sand, clay and water. Due to this type of moulding requiring long periods of training to master, simpler sand systems were developed that involved dry silica without any clay. This type of moulding involves a resin and catalyst for bonding purposes, and is the type of system that Durham Foundry currently use.

Wear Resistant & Ni Hard Cast Iron Castings

Cast iron used for applications such as bearing housings, gearboxes and machine beds has a hardness between 150 and 200 Brinell, but the addition of alloying elements such as chrome or copper can bring the hardness to over 700 Brinell. This increased hardness allows cast iron to be used in contexts that demand wear resistance, such as in mixer paddles, clay augurs and dies, ball mill liner plates, wire drawing guides and shotblast spares. Highly alloyed iron such as this is often described in various ways, which can cause confusion. As such, Durham Foundry are happy to give advice on what grade should be used.

Ductile Iron Castings & Ductile Cast Iron

Due to the flakes of graphite that form in cast iron that is allowed to cool normally, it has near to no elongation, making it brittle and unsuitable for tensile and shock loading applications. As such, foundrymen and metallurgists spent years trying to develop a type of iron that could be used for these applications while also being produced at the low cost that grey cast iron is. The addition of magnesium resulted in iron with spheres of graphite in, rather than flakes; a difference that made the iron ductile due to the spheres acting as crack arresters.

Grey Iron Castings & Grey Cast Iron

The Durham Foundry method of grey iron production involves a melt of pig iron and steel scrap, with carbon, ferro silicon, ferro manganese, ferro sulphide and zirconium based ferro silicon innoculant additions. Small quantities of copper, vanadium, molybdenum or chrome can be used as alloys to produce stronger irons. Alloyed grey irons such as these are more suitable for applications that require more tensile strength or hardness, and in some cases can produce an iron that responds to heat treatment.

Austenitic Castings & Ni Resist Cast Iron

To produce austenitic cast iron, normal grey iron or ductile iron melts have their carbon and silicon controlled at lower levels, and have alloys added. This produces a stable austenitic structure at an ambient temperature. The alternate name of Ni resist comes from nickel being the primary alloying element, stabilising the austenite structure during the solidification process. Due to this nickel content, austenitic cast iron costs more than grey or ductile iron, but generally costs less than alloyed steel. This is particularly true if machining and casting costs are taken into account.

Compacted Graphite Iron Castings - CGI Castings

Compacted graphite iron (CGI or vermicular graphite iron) is cast iron with graphite particles that are somewhere between flakes and spheres, with more of a worm-like shape. This shape provides the most useful properties seen in grey and ductile irons; CGI is twice as strong as grey iron but is as cheap as ductile iron. While grey iron is simple to make, its brittle structure doesn't provide good tensile strength, and ductile iron may have a high tensile strength, but it is a fairly poor thermal conductor and is lacking in damping properties. CGI balances the conductivity and damping of grey iron with the tensile strength of ductile iron.

Austempered Ductile Iron Castings - ADI Castings

Standard ductile iron can be given a special austempering heat treatment to produce austempered ductile iron (ADI or ausferritic ductile iron). It maintains the elongation and toughness of pearlitic ductile iron, but is almost twice as strong. Such a combination makes ADI a much more wear resistant and strong material than standard ductile iron, cast or forged aluminium and some cast and forged steels.The aforementioned properties of these irons are principally due to the metal matrices. In conventional ductile iron, the matrix is a mixture of pearlite and ferrite, while ADI has a matrix of acicular ferrite and carbon stabilized austenite, known as ausferrite.

Bespoke Cast Iron & Bespoke Iron Castings

Since molten cast iron is particularly fluid (as well as being a relatively cheap metal) it is very suitable for bespoke castings, whether they be for the decorative, architectural or sculptural sectors. Since the development of ductile cast iron, bespoke castings can be produced with more structural applications, due to their greater ability to withstand loading.Clients often have sketches or photographs to represent their bespoke casting idea, and we are very capable of developing something from this information. We can of course also advise clients on what grade of iron would be best suited for their casting needs.

Georgian & Victorian Cast Iron Fireplaces

We have a whole range of Georgian and Victorian fireplaces that are unique to Durham Foundry, as well as a large amount of samples and designs that allow us to replace missing grates or hoods on existing fireplaces. Our fireplaces can be provided individually for retail or in batches for wholesale.We can also renovate old fireplaces and if you need new or reconditioned fires fitting with grates then we can recommend installers. Our new fireplaces can also be fitted with solid fuel or gas grates.

Cast Iron Fireplaces - Georgian & Victorian

Fireplaces have not only been a source of heat for a long time, but decorative focal points as well. For a while, they were a commodity exclusive to the wealthy, but the Georgian and Victorian periods saw a rise of the middle class that brought with it a demand for cheaper materials. As previously mentioned, cast iron saw a boom at this time, and one of its applications was as fireplaces for the middle and working classes. Companies began developing wide ranges of decorative fireplace designs that were readily available to the common man. This has continued to this day, as our range of fireplaces reflect the importance that iron still has in the manufacture of decorative and stylish fireplaces.

Cast Iron Street Furniture and Ornamental Street Furniture

Cast iron saw an increase in use for municipal castings and street furniture in the early 50s due to the development of ductile cast iron. The properties of this new type of iron allowed it to find applications that regular cast iron was not suitable for, and decorative castings could now be produced for uses that demanded better structural qualities.Traditional and ductile cast iron are still used in various street furniture applications and are likely to continue being used in such projects. It is a much more cost efficient material than alternatives such as steel and brass, which is why it is perfect for the manufacture of gates, railings, lamp posts, columns, waste bins, floor grates and seating.

Architectural Railing Finials

At Durham Foundry we produce a range of railing finials, which can be provided in grey or ductile iron, either as cast or primer painted. Batch sizes are 10 off minimum for any of the designs. Our finials come in a variety of different designs, from ornate to more simple designs. Dimensions also vary, so check our website to view the designs and their respective dimensions.

Engineering Castings & Engineering Cast Iron

Prior to the industrial revolution, the use of forged iron was made impractical due to the difficulty in controlling how much carbon and silicon was in the iron to allow for a reproducible analysis, as well as to get the iron to a molten temperature for casting. The industrial revolution saw greater analysis and production of iron, which in turn made it a more reliable material with a better molten fluidity – perfect for casting complicated shapes. This revolutionised its use in engineering and structural applications, as cast iron could be used to cast complicated components in one piece, where wrought iron had necessitated the production of several separate pieces.

Architectural Cast Iron & Architectural Iron Castings

At Durham Foundry, we produce architectural castings in two main categories; new projects and restoration. Our new project castings may be modern designs, or traditional, even replicas of existing pieces. In the case of restoration, we dismantle the existing structure, conserve the castings that are in good condition, and manufacture replacements for any that necessitate renewal. We then clean, paint and reassemble the castings.We have developed a relationship with Casting Repairs Ltd due to our ability to provide castings for renovation purposes, and since old cast iron buildings and structures often have historical significance, we are also used to working with organisations like English Heritage to assure that the correct standards are reached.

Decorative Cast Iron & Decorative Iron Castings

Prior to the Georgian period, brass and bronze were most commonly used for decoration, which made metal decorations a luxury for the wealthy. But with the advent of cast iron as a cheap and versatile substance, metal decorations became available to a wider range of people, and the majority of metal decorations seen on Georgian and Victorian buildings are indeed cast iron.Cast iron's ability to be shaped with great detail has assured that it remains a strong choice for decorative castings, and its longevity has meant that many iron cast decorations are still used today.

Manuals & Brochures

Details

Info

| Registration Number: | 02544846 |

| VAT Number: | GB534 0805 67 |

| Registered at Companies House: | 1 October, 1990 (33 years and 7 months ago) |

| No of Employees: | 21-50 |

| Annual Turnover: | 1-2m |

| Parent Company: | C Butcher and Co Ltd |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Questions

Additional Information

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Cushioning Foam

- MO PHO VIET CAFE LTD

- Beagle Construction Ltd

- Bistro Seating

- Kot Importers & Exporters Ltd

- Companies beginning with G

- Ashe Morris Ltd

- Hedgehogs At Work Ltd

- FDA, USDA Belt Compliant Conveyors

- Kbb Design Company Ltd

- Paneltech Systems Ltd

- Kr.Eativ: Architects Ltd

- Ferguson Engineering Services Ltd

- Portman Place Sherborne Management Company Ltd

- Saint Nicolas Ltd

- JCW Acoustic Supplies Ltd

- Promotional Mats

- Kv Management Services Ltd

- Marine graphics