- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Tritex NDT Ltd

Overview

- Mr Jon Sharland - Sales Manager

- JONES, Stephen Kevin - Director

- MEECH, Patrick James - Director

- SHARLAND, Jonathan Robert - Director

Products

Tritex NDT – NDT stands for non-destructive testing – is a market leader in the specialised work of thickness gauging. We have designed and developed a range of products, with our long experience and unique understanding of thickness gauging, to offer our customers a full complement of tools suitable to their needs across a number of industries. Our Technicians pioneered, for instance, multiple echo features in handheld tools in the early 1980s. And we have a deep knowledge of the challenges our customers face in NDT work: so we aim to offer the best solutions. Our Multiple Echo method of testing means that we can gauge thicknesses without damaging protective coatings. And we are proud to build products that leave out hazardous substances; our environmental commitment is demonstrated by the fact that our products conform to RoHS and WEEE standards. Tritex NDT is an ISO9001:2008 certified company.

Multigauge 5500 Ultrasonic Thickness Gauge

We offer the Multigauge 5500 for hands-free use by operators mounted on staging, scaffolding, ladders, or suspended by rope. A single crystal soft-faced probe operates at 2.25MHz, 3.5MHz, or 5MHz, with a measurement range of 1mm to 250mm. The Multiple Echo technology ignores coatings on surfaces up to 6mm thick, with automatic measurement verification, and is built with a rugged casing and easy-to-use interface. Please visit our website for full product details.

Multigauge 5600 Ultrasonic Thickness Gauge

We offer the Multigauge 5600 as a simple and robust ultrasonic thickness gauge suitable for most standard gauging applications. An easy-to-use keypad interface and bright LCD display mean that the product can be used in any lighting condition – while the moulded soft rubber casing is comfortable to use and durable. A single crystal soft-faced probe operates at 2.25MHz, 3.5MHz, or 5MHz, with a measurement range of 1mm to 250mm. The Multiple Echo technology ignores coatings on surfaces up to 6mm thick, with automatic measurement verification, and the interface offers easy calibration during testing. Please visit our website for full product details.

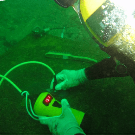

Multigauge 3000 Underwater Thickness Gauge

We offer the Multigauge 3000 for challenging underwater thickness gauging operations. Robust and easy-to-use gauge, designed for most underwater measuring contexts, the Multigauge 3000 has been pressure-tested to 500 metres and can survive harsh conditions in offshore and underwater industrial work. A 10mm display offers high readability in poor visibility environments – or the device can transfer measurements to a surface display unit. The product has a single crystal soft-faced probe operates at 2.25MHz, 3.5MHz, or 5MHz, with a measurement range of 1mm to 250mm. And the Multiple Echo technology ignores coatings on surfaces up to 6mm thick with automatic measurement verification. The product can be used for 55 hours on a single fast battery charge. Please visit our website for full product details.

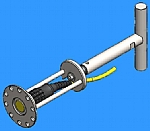

Multigauge 4100 and 4400 Underwater/ROV Thickness Gauges

We offer two measurement gauges for mounting on all types of work-class remotely-operated underwater vehicles (ROVs). The Multigauge 4100 has a depth rating of 1,000 metres while the Multigauge 4400 has a depth rating of 4,000 metres. Both have been designed to operate in the harsh conditions of offshore and underwater industrial work. The products use multiple echo for easy taking of measurements while ignoring coating of up to 6mm thick. And the user-selectable RS422 or RS232 output means that connecting to ROVs is easy. The product has a single crystal soft-faced probe operates at 2.25MHz, 3.5MHz, or 5MHz, with a measurement range of 1mm to 250mm. Please visit our website for full product details.

Multigauge ROV Probe Holder

We offer the Multigauge ROV Probe Holder to accurately and delicately present an ROV-mounted measurement probe to the surface to be measured, whether curved or flat, in a way that maintains the integrity of the surface while avoiding any silt or seaweed clogging in the underwater environment. Our Probe Holder can be used with most types of ROVs. The product offers a 75-degree freedom of movement in all directions without any axial restriction. We build the Probe Holder from titanium for lightness and strength. Please visit our website for full product details.

Applications - Shipping

Monitoring corrosion levels is essential to the safe and efficient operation of ships. Our Multigauges can measure the thickness of metal – whether there has been any literal wear or tear – in even the most challenging of seafaring environments. Our probes can even be used on pitted surfaces to give a true thickness measurement from the bottom of the pit to the back wall of the metal hull.

Applications - Offshore

Offshore industrial work presents challenging environments that demand frequent metal testing and measurement with tools that are reliable and durable. Corrosion is a danger that must be monitored and our Multigauges are perfect for inspecting pipelines, ship hulls, cranes, cylinders, offshore platform risers, and oil rigs.

Applications - Rope Access

Our Multigauge 5500 can be mounted on to the chest harness of a rope access system – eliminating the need to wear the Multigauge from a belt or round the beck. This is an exceptional convenience in an otherwise physically and mentally demanding operational environment. The probe is there when you need it, suspended from the rope access harness, and can be tidily stowed when it is not in use.

Applications - Pipelines

Pipeline networks are one of the foundations of the global economy – oil, gas, and chemicals, are all transported from country to country through an extensive series of pipelines. Corrosion, environmental damage, and human harm are severe risks if pipelines are damaged. Our Multigauges allow operators to conduct ultrasonic thickness inspections on pipelines to avoid costly and damaging leaks.

Applications - Storage Tanks

Corrosion of storage tanks containing hazardous substances such as chemicals and petroleum can have calamitous results and therefore regular monitoring of the tanks is paramount to ensure potential accidents are avoided. In particular, tanks that are used to store liquified petroleum gas (LPG) are particularly prone to corrosion and routine checks should be carried out to ensure thickness levels are at a safe level. Tritex multigauges are a cost effective and easy way of conducting thickness checks accurately and our Multigauge 5500, with its belt clip, is particularly user friendly when working on ropes, ladders or scaffolding.

Applications - Lighting Columns

Corrosion at the base and collar joint of lighting columns is common as a result of ground water, condensation and splashes of water from passing vehicles. As lighting columns are often in public places it is important they are regularly inspected to avoid any accidents caused by the column falling down and this is often undertaken by local governments.

Applications - Road Tankers

Routine inspections of road tankers is essential in order for potential accidents to be avoided and the use of thickness gauges is a highly effective and practicable way of conducting a corrosion assessment as tankers corrode from the inside. Our ultra sensitive gauges will discount any coatings and decals on the surface of the tanker and will allow you to measure the thickness of the metal only.

Applications - Bridges

Depending on the type, bridges are required to be inspected every 2 to 6 years to ensure they are fit for purpose and can continue to be used safely. Titrex multigauges can be used to monitor metal thickness across the bridge structure, taking into account any surface rust that may be present from weathering.

Applications - General Industry

Many factories utilise tanks and pipelines for storing chemicals and also for moving them from one part of the site to another and these pipes and tanks are liable to deterioration over time and Tritex multigauges make monitoring the corrosion easy and cost effective. Regular monitoring of the tanks and pipes will ensure early detection of corrosion, which left untreated, could result in devastating accidents. Tritex multigauges are very versatile and can be used as a monitoring apparatus in a multitude of situations such as measuring boiler tubes, monitoring wear on machinery and the condition of plant asset, and can also be used for inspecting metal structures.

Applications - Underwater

All underwater structures, especially those in a sea water environment which are particularly prone to corrosion, should be subjected to regular assessment in order for early damage to be identified and treated. Tritex’s Multigauge 3000 has been designed for taking accurate underwater thickness measurements for a wide range of underwater applications including pipelines, offshore platforms, ships, piers, bridges, pilings and lock gates. The Multigauge 3000 allows divers to take accurate readings without removing any coatings on the metal in question and its large LED screen means measurements can be taken even when visibility is poor.

Other Applications

Aside from those listed above, our multigauges are suitable for using on any metal, as the nature of metal inherently means it is susceptible to corrosion. Other applications include mobile phone masts, children’s’ playground equipment, gas cylinders, boilers and boiler tubes, trains, fairground attractions, surveillance camera masts, electricity pylons, windmills and quality assurance. Please contact us to discuss the most suitable gauge for your requirements.

Technology

Tritex multigauges utilise multiple echo to measure the thickness of metals. The gauge transmits an ultrasound pulse which then penetrates the metal and any coating it may have on it. This ultrasound is then reflected back and echos within the metal. As the coatings will have a different velocity of sound to the metal only a small amount of the ultrasound goes back through the coating and this timing correlates to the timing of the echo in the metal and allows a measurement for the thickness of the metal only to be calculated. The gauge works on an Automatic Measurement Veriftication System whereby a minimum of three readings are taken to ensure optimum accuracy.

Manuals & Brochures

Details

Info

| Registration Number: | 05685071 |

| VAT Number: | GB305 2595 73 |

| Registered at Companies House: | 23 January, 2006 (18 years and 3 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Brand & Trade Names

- Multigauge 3000 Multigauge Underwater Thickness Gauge

- Multigauge 4000 Series Multigauge Underwater Thickness Gauge

- Multigauge 5500 Multigauge Ultrasonic Thickness Gauge

- Multigauge 5600 Multigauge Ultrasonic Thickness Gauge

Products & Services

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Digital Balancing Machines

- Automation Engineering

- Shoe Making Machinery

- Louise Bush 1728 Ltd

- Thirty Four Stores Ltd

- The Audit & Risk Recruitment Company Ltd

- Duc Tien Cash & Carry Ltd

- Kaisertech Ltd

- S.V.S. Designs Ltd

- HAYES

- FERRIER SOFTWARE DEVELOPMENT Ltd

- The Chauffeur Service Ltd

- Charles Darrow (North Devon) Ltd

- University of Derby, Buxton

- Signage

- Jaz Dhami Ltd

- Go Greener Energy Ltd

- Rubber Safety Mats

- Tom Lambert Consulting Ltd