- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Quality Blasting

Overview

Products

Quality Blasting is one of the UK's leading shot blasting service providers. We offer low-cost, high quality solutions for weldmark and paint removal, descaling, abrasive cleaning, wood distressing, and metalwork finishing. Our services - which include automatic blasting, room blasting, and hand cabinet blasting - are valued by customers across a broad spectrum of industries, including steel manufacturing, food processing, automotive, defence, health and safety, marine, steel profiling and many more. Automatic blasting is used predominantly for commercial blasting, cleaning, or surface profiling - this involves the use of several large tumbler machines. Room blasting caters for work on a significantly larger scale - we use separate blast rooms located in different work units to prevent cross contamination of ferrous and non-ferrous materials. Hand cabinet services are typically used for small or large items that cannot be tumble blasted. Our experts are able to offer advice and guidance on the most suitable blasting process for your needs. At Quality Blasting, we also run a professional restoration service that deals with anything from fireplaces, decorative ironwork and household items to classic cars, motorbikes and bicycles. Quality Blasting has strong reputation for the quality and speed of its service - most of our new work comes from work of mouth referrals. We continue to make investments into the very latest processes, technologies and plant so that our customers receive the best possible service. So whatever your surface/finish requirements, get in touch with Quality Blasting. Visit our website or give us a call today and speak to one of our expert representatives.

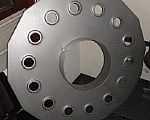

Shot Blasting

Shot Blasting is a technique that is usually employed for the removal of corrosion, paint, mill scale or rust, giving the surface a good key finish for coating if required. It involves the use of abrasives such as grit, glass bead, steel shot or aluminium oxide applied at high speed to the surface of an object from a specified distance. By adjusting the pressure, nozzle size and nozzle distance, you can alter the effect of the blasting process according to your requirements. The selection of abrasive media depends on the condition of the material before blasting and the finish required afterwards.

Restoration Service

Quality Blasting offers professional restoration service for a wide range of domestic objects, including decorative ironwork, fireplaces, tools, and radiators, as well as classic and contemporary cars, motorbikes and bicycles. You can view our price guide by visiting the Quality Blasting website, or you can get in touch for a free, no obligation quote.

Quality

Quality is something that we take great pride in. And this applied not only to our blasting services, but also to the level of our customer service. We implement full quality control procedures using visual monitoring, DFTs and Almen Arc strips for relevant testing areas, while we also issue certificates of conformity for consistent data recording and assessment. All stages of the production process are visually inspected, while Dry Film Thickness testing of coatings is undertaken electronically. Our measuring equipment is calibrated on a regular basis. To find out more about how we ensure quality, please head directly to the Quality Blasting website. If you have any specific questions, please do not hesitate to get in touch.

Shot Peening

Shot peening is a cold working process in which small dimples are created on the surface which increase material resistance to fatigue failures, stress corrosion and galling. This process is specifically used in the production of gears, chains and welded parts, and is commonly employed in the aerospace industry. If you would like to find out more about our shot peening services, please visit the Quality Blasting website or give us call.

Automatic Blasting

This involves the use of various sizes of ball shot and grit to remove coatings, paint or powder coating. Rubber belted machines tumble items in bulk for blasting on a large scale. It is a process most suited for high volumes. For further information on our automatic blasting services, get in touch with our experts via telephone.

Room Blasting

The use of separate blast rooms located in different work units prevents cross contamination between ferrous and non-ferrous abrasives. Ferrous abrasives such as grit and ball shot are used for the elimination of paint, rust, foundry sand and mill scale. This leaves the material with a suitable key for painting or powder coating. Non-ferrous abrasives such as aluminium oxide or glass bead are employed to achieve a consistent and uniform finish on both aluminium and stainless steel products. Maximum room capacity for both blasting processes is 7m x 3.25m x 2.5m. To find out more about our room basting services, please head directly to the Quality Blasting website.

Hand Cabinets

Our hand cabinet blasting has been designed for use with single delicate items. Once the item is placed with the cabinet, a blasting process which utilises glass beads is initiated. Just one example of the types of items which could benefit from this type of service is plastic grilles. If you have any questions or would like further information, don't hesitate to visit the website or you can contact us directly by phone or email.

Details

Info

| Registration Number: | 05021739 |

| VAT Number: | GB851 9861 89 |

| Registered at Companies House: | 21 January, 2004 (20 years and 3 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Parent Company: | Tecwin Ltd |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Beckford Social Work Ltd

- Instrument Hire, Lease, Rent

- Ball Bearings

- OB SERVICES LTD

- Jerry's Logistics Ltd

- Tees Rivers Charitable Trust

- The Old Dairy (Streatham) Management Company Ltd

- Companies beginning with S

- THE PIMLICO GARDENING COMPANY Ltd

- Display Screens

- Oil & Gas Industry Fabricators

- CAMBA HOLDING Ltd

- Visceral Occlusion Ltd

- Power Investments London Ltd

- Thrive on Five Ltd

- Induction Hobs

- Copolymer Plant

- BUY BEAUTIFUL LTD

- Jacketed Vessels