- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Premier Hytemp

Overview

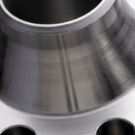

Products

Premier Hytemp supplies the industry with a fantastic

range of quality engineered materials including nickel alloys, stainless steel

and low alloys (includes alloy 718, alloy 625, alloy 825, alloy 925, alloy 725,

alloy A20, steel F44, steel F51, steel F55, steel 410, steel 420, steel 17/4

PH, steel A286, steel F6NM, Nitronic 50 and Nitronic 60).

Edinburgh based, Premier Hytemp forms a division of The

Murray Group – a world leading engineered solution provider, stockist and

supplier of low alloy, stainless steel and nickel alloy forged bar, open die

forged and closed dire forged products for various industries such as oil and

gas, heavy industry, ship builing, aerospace, nuclear and water processing.

With more than 30 years experience in the industry,

Premier Hytemp is widely recognised as an approved global supplier to major

manufacturers in the oil and gas wellhead, downhole tools and well construction

industries. Our experience enables us to provide engineered solutions that meet

customer requirements quickly and efficiently.

We are ISO9001 approved and all materials are fully

traceable. Whether you require raw materials, bar, forged products, finish

machined products or complete assemblies, Premier Hytemp is the company to

call.

Low alloy steel

Premier Hytemp provides the industry with a complete

range of low alloy steel grades. This range can be delivered to customers in

almost any configuration required including:

Saw cut normalised bar lengths

Saw cut annealed bar lengths

Saw cut heat-treated bar lengths

Finshed machines products of different shapes

Roughed out and heat-treated to specification

Certified and function tested products

Please follow the link to our website to view our low

alloy steel inventory. The range includes alloy 4130, alloy 4140, alloy 4145,

alloy 4330V and alloy F22.

Stainless steel

We also offer a comprehensive range of stainless steel grades. This range can be supplied to customers in almost any configuration required such as:Saw cut normalised/ heat treated bar lengths

Finished machined products of different shapes

Roughed out and heat treated to specification

Certified and function tested products

Please follow the link to our website to view our stainless steel inventory. The range includes Austenitic F44 steel, Duplex F51 steel. Super Duplex F55 steel, Martensitic 410 steel, Ppt Hardening 17/4 PH steel, Martensitic F6NM steel, Austenitic Nitronic 50 and Austenitic Nitronic 60.

Nickel alloy

Our range of nickel alloy grades includes Inconel alloy 625, Inconel alloy 718, Inconel alloy 825, Inconel alloy 925 and Ni Cr Fe alloy A20. These alloys can be supplied in various forms to suit specific requirements. Examples include:Saw cut normalised/ heat treated bar lengths

Finished machined products of different shapes

Roughed out and heat treated to specification

Certified and function tested products

Please visit our website to find out more about our excellent range of nickel alloys or please contact our friendly team at Premier Hytemp for further information and advice.

Bar stock

We are pleased to hold an excellent inventory of 625 and 718 nickel alloy bar stock at our Montrose and Newbridge warehouses. This enables us to provide a rapid and reliable delivery service to our customers. Our certified nickel alloy range features high strength, ductility, toughness, excellent corrosion resistance and good welding characteristics. These qualities make them ideal for use in wellhead and downhole applications. Please visit our website to view our table of sizes and finishes. Alternatively, please contact us at Premier Hytemp to find out more about our bar stock and delivery.

Services delivered

Alongside our supply of stock material and components we also provide customers with a range of services including:Heat Treatment: Our highly skilled team heat treats components after processing in order to produce materials with the exact properties required by the customer.

Testing: We also carry out testing at various stages of production to ensure materials meet customer requirements. All of our components are hardness tested and ultrasonically tested for defects.

Sawing and Proof Machining: We recommend customers order proof machined materials to eliminate any possibility of sub-surface defects.

Final Machining: We are pleased to provide customers with fully machined components to meet specifications.

Sawing and machine capabilities

Here at Premier Hytemp we are continually developing our range of equipment in order to provide customers with the highest quality products and services. Our team uses a wide range of state of the art equipment in order to achieve all kinds of sawing and machining solutions. We have the facilities to saw in all grades up to 1300mm diameter and the capabilities for deephole boring up to 12 meters in length with outside diameter up to 650mm.Please visit our website to find out more about out types of sawing machines and capabilities or for further information please call us at Premier Hytemp and we will be happy to provide all the information you may need.

Premier Quality

Premier Hytemp is extremely proud of its talented and dedicated workforce. All of our employees are experts in their field and provide the industry with outstanding solutions. Our high level of expertise enables us to provide a market leading level of technical service. We continually monitor and research the industry in order to develop the business to meet demand effectively. We update machinery and equipment on a regular bases and look at innovative ways to improve our services, enhance efficiency and increase market share. We also maintain strict quality control procedures. To find out more about our ISO 9001 Certificate of Approval please follow the link to our website.

Environment

Here at Premier Hytemp we feel strongly about the environment and understand the damaging affects that production has on the environment. We therefore carry out regular reviews in order to create production strategies that keep our impact to a minimum. Our employees work together to carry out these strategies and steps effectively. Please visit our website to download and view our Environmental Policy.

Health & Safety

Premier Hytemp takes strict measures to safeguard the health, safety and welfare of its employees and visitors to its premises. The Health and Safety at Work Act 1974 imposes statutory duties on employers and employees and it is our policy to ensure that all health and safety steps and policies are properly assigned, accepted and fulfilled at all levels of our organisation.

Supply chain experts

Premier Hytemp provides services via its supply-chain delivery services to customers based all around the world. We supply particularly high volumes to Europe, Scandinavia, North and South America, Canada, the Middle East, Africa, the Far East and Australasia. With a full service facility in Singapore, experienced agents based in Brazil, France, India and Australia, and offices and stock in Houston USA Premier Hytemp has a serious global presence.

Wellheads

Our highly experienced team specialises in the manufacture of products suitable for use in some of the most arduous and extreme working environments around the world. We supply quality controlled and certified products suitable for use in the most challenging and demanding of applications. We supply inconels and stainless steel for applications such as:Safety critical tubing hangers to avoid loss of oil gas output

Liners, seals and actuator stems

Pipeline connectors and seals

Injector blocks

Bosses and well neck flanges

Gates, seats and stems for gate valves in Christmas trees, eliminating or minimising costly maintenance

Valves

Here at Premier Hytemp we manufacture metal valve and components to extremely high standards. Our metal valves and components are widely used in industries such as petrochemical, power generation and nuclear installations. It is essential that metal valve and components are manufactured to such as standard that they can withstand heat, pressure or corrosive affects in demanding working environments. We are pleased to manufacture and supply components for the following applications:Gate Valves – gates, seats, stems and seals

Ball Valves: balls, seats, stems and seals

Check Valves: seats, stems and seals

Wedge Valves: seats, stems and seals

Butterfly and other valve, seats, stems and seals

Downhole

We are also pleased to provide metal materials and products to the highest specification levels suitable for downhole applications. Our quality controlled and certified products meet the most demanding of mission critical, fail safe and output loss requirements. We largely supply nickel alloy and high grade stainless steel solutions for downhole tooling including:Linear hangers

Packers

Whipstock

Blast Joint

Polish Bore Receptacles (PBR)

Flow Control

Pup Joints

Safety Valves

Please contact us at Premier Hytemp to find out more about our downhole tooling capabilities.

Customers

Please visit our website or contact us at Premier Hytemp to find out more about our worldwide customer base. We are in direct link with global OEMs and have been involved with major projects in offshore Angola, Brazil, South East Asia and Gulf of Mexico and onshore Africa, USA and Canada.

Contact

Please contact us at Premier Hytemp with all of your enquiries.Premier Hytemp

24 Chambers Way

Thorncliffe Park, Chapeltown

Sheffield, England, S35 2PH

Tel: +44(0)114 257 0910

Fax: +44(0)114 245 4364

Alternatively, please visit our website where you can complete our online enquiries form and we will respond directly as soon as possible.

News

Please visit our website to find out more about our business and the industry via our News and Announcements page. Our latest post ‘Cabin Secretary for Finance, Employment and Sustainable Growth visits Premier Hytemp’ is an interesting read accompanied by a video. You can also subscribe to the Premier Hytemp newsfeed to get up to date information as it published.

Details

Info

| Registration Number: | SC093051 |

| VAT Number: | n/a |

| Registered at Companies House: | 26 April, 1985 (38 years and 11 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: |

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Crown & Anchor (Manchester) Ltd

- Animal Nutrition

- Electromechanical Products

- Merit Solutions (London) Ltd

- UWI Circle Ltd

- Best Windings Ltd

- Hydraulic Brakes

- TRUE CARE SUPPLIES Ltd

- Interface Vehicle Services

- Metal Craft Fabrications (Havant) Ltd

- Anetic Aid Ltd

- Hamilton Estates North West Ltd

- Life Fwd Ltd

- Adhesive Dispensers

- Victoria Care Home (Burnley) Ltd

- Franklite Ltd

- Companies beginning with A

- Kitchenware Trade Suppliers

- Cable and Conductor Taping Machines