- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Mobility Engineering (Cheshire) Ltd

Overview

Products

Established in 1974, Mobility Engineering (Cheshire) Ltd manufactures and supplies conveyors and conveyor systems to all types of industries. With over 30 years in the business, the team at Mobility Engineering Ltd, based in Lymm, Cheshire, are experts in their field and offer an experienced service to their clients. Using state of the art AutoCAD design software, experienced engineering staff design, manufacture and commission all material handling systems ensuring the highest quality of outputs and fast and efficient lead times. Alongside our standard range of conveyor products, we provide a bespoke service whereby we tailor designs to meet the requirements of the individual ensuring that the conveyor system fulfils its expectations. Our sister company, Roll-Ezy Ltd was established in 1994 and manufactures conveyor rollers and conveyor components to Mobility Engineering Ltd as well as other conveyor manufacturers in the industry.

Belt Conveyors - Visit our website

Our standard belt conveyors are motor powered conveyors that are commonly used on assembly/packing lines where they carry products to and from packing stations. They can be assembled to form straight lines, inclines and bends for full production lines. Belts come in various shapes and sizes and belt conveyors can run from 3m per minute up to approximately 50m per minute. We work closely with clients' requirements and specifications to create belt conveyor systems that will facilitate the load weights they will be handling.

PVC/PU Belt Conveyors - Visit our website

Pvc/Pu belt conveyors are one of our most popular products and widely used due to their cost-effectiveness and efficiency. Our traditional Pvc belt conveyors are used within picking or assembly lines as well as for horizontal packing while we would recommend food grade Pu belt conveyors for use in the food industry. Mobility Engineering (Cheshire) has years of experience in this field and we can make the right recommendations such as a grip face rubber belt if elevation is required including belt flights for inclines over 24 degrees. We also offer woven back belts for additional end and return roller grip as well as providing belts with tracking strip profiles to eliminate the need for tracking.

Modular Belt Conveyors - Visit our website

Modular belt conveyors offer long lasting durability and an enhanced lifespan making them among the most cost effective conveyor belt systems available. Our range of modular belt conveyors, including our Pvc/Pu belt conveyors, are extensively used for applications including assembly and packing as well as being the ideal solution for use in the food and pharmaceutical industries. We offer modular belt conveyors constructed from polypropylene, polyethylene and polyacetal, and we can assess your needs and make recommendations on the right conveyors to meet your requirements. Our belts consist of a series of links, which means conveyors can be constructed to customer requirements including narrow links, opened top flush grids, radius flush grids for bends and grip tops for inclines.

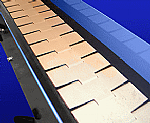

Slat Conveyors - Visit our website

We offer a range of standard sized belt conveyors with smooth and grip top belts. We also manufacture slat conveyors to meet your specific requirements. Slat conveyors can open up slightly around a bend enabling a very tight radius to be achieved. Slats are usually manufactured from a material called acetal which is a hard, heat resistant plastic, or from stainless steel. Both of these materials are side flexing for bend sections and range from widths of approximately 80mm to 300mm. Our slat conveyors are commonly used and perfectly suited to food and pharmaceutical industries where speed and accuracy is paramount. Slat conveyors are also easy to clean and maintain.

Plastic Slat Conveyors - Visit our website

Our plastic slat conveyors are the ideal solution when rapid speed and accuracy are a priority. Our plastic slat conveyors are widely used in a diversity of industries including the food and pharmaceutical sectors. Our plastic/acetal slat conveyors are generally used to move lighter products such as plastic tubs, ice cream pots and yoghurts, etc in the food industry. Another major benefit of the plastic slat conveyors for the food industry is that they are easily cleaned for hygiene purposes. The design of the plastic slat conveyors allows for rapid throughputs in a variety of configurations including short bend radi as well as allowing for product accumulation.

Steel Slat Conveyors - Visit our website

Our steel slat conveyors are widely used throughout the food and pharmaceuticals industry where high speed and precise accuracy are a priority. The premier quality, durable steel used makes the steel slat conveyors suitable for use in heavier industry including the handling of heavy steel products such as the automotive industry parts or punched and pressed parts. The slats are usually constructed from stainless steel, which are suitable for use in both wet conditions as well as in environments where dirt is an issue. Stainless steel is also the preferred slat construction choice due to its longevity and enhanced lifespan.

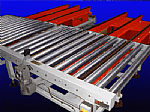

Roller Conveyors - Visit our website

Our roller conveyors are contained within a frame and are adapted to the required length, width and height of the client. We design, manufacture and supply standard and bespoke roller conveyors for applications in various industries. There are three main categories of roller conveyors:

Gravity Roller Conveyors: these are for manual handling processes for light or heavy products. Products are either pushed along the conveyor by hand, or flow down the track via gravity.

Lineshaft Powered Roller Conveyors: These are powered by a drive shaft beneath the rollers. They are suitable for automatically conveying light products.

Chain Driven Powered Roller Conveyors: These heavy duty and robust rollers are used for heavier products such as pallets of loads (usually) up to 1,500kgs, but can easily be adapted to handle loads of up to 7,000kgs.

Gravity Roller Conveyors - Visit our website

As the name suggests, gravity roller conveyors use gravity to move products and as no power is needed offer a very cost-effective way of product transportation. Our gravity roller conveyor systems are widely used within industries for moving a range of products including plastic totes, conveying trays, cardboard boxes and slave boards. The products can be moved along the gravity system either horizontally across the incorporated rollers or by the means of slight decline on the system. Gravity roller systems come in a range of diameter sizes and finishes with lengths manufactured to meet customer requirements. The modular design means the gravity systems can be used independently or linked to the end of a power driven system.

Chain Driven Roller Conveyor - Visit our website

For a heavy duty powered conveyor our chain driven roller conveyor/pallet roller conveyor will be the ideal solution. These conveyors are primarily used for moving heavy products such as pallets and drums. Our chain driven roller conveyors are constructed with heavy duty components and can feature powered turntables and 90° cross transfers. Chain driven powered roller conveyors are widely used throughout production plants for automotive manufacturing and pallet handling including applications such as assembly and test lines as well as for full production. We offer a full range of accessories including blade stops, entry guides, powered turntables, merges and control system options.

Lineshaft Roller Conveyor - Visit our website

Our Lineshaft powered roller conveyors are the ideal solution for applications such as simple product conveying or back to back product accumulation without pressure on the leading product. The Lineshaft powered roller conveyer typically handles products of around 30kg and is an economical solution featuring an external motor that turns inside of the nylon spool instead of a belt driven operation; this conveyor provides curve section angles of 30°, 45°, 60° and 90°. Benefits of the Lineshaft powered roller conveyor include high energy efficiency, versatile and economic powered conveying, minimal line pressure accumulation and system flexibility via the modular construction.

Gravity Flex Conveyors - Visit our website

Our Gravityflex roller skatewheel conveyors offer enhanced flexibility and adaptability thanks to their innovative extension and retraction capabilities. The lengths of the Gravityflex conveyor can be altered to suit as well as being manipulated to form bends and curves. We manufacture our Gravityflex conveyors to our customer’s specific requirements. We assess details such as weights and dimensions of the product as well as the production environment to ensure that our customers receive the right Gravityflex for the job. Once extended, our rollers and skatewheels offer a 125mm pitch with the skatewheels pitched at 100mm across the width featuring a staggered effect for a smoother run.

Chain Conveyors - Visit our website

Chain conveyors are an essential tool for transporting heavy or awkward shaped loads that are not suitable to be handled on roller conveyors. The chains sit and run within guides that carry the load. Like all of our products and services, our chain rollers have developed over the years to perfectly suit clients' requirements. They are easy to assemble, install and maintain and can be quickly tailored and built to meet client specifications.

Chain conveyors are commonly used in automotive industries for handling awkward automotive parts, car bodies, chassis etc and various industrial industries.

Magnetic Conveyors - Visit our website

Magnetic Conveyers – often viewed as “Magic” Conveyors due to the fact that you cannot see any moving mechanical parts – are used to transport small mild steel objects that are fed from an internal conveyor found either directly beneath a press or outside the press. Magnetic bars attached to a twin strand chain conveyor beneath the surface convey the metal parts in the direction required. Magnetic Conveyors can be built to various specifications in either horizontal or “swan neck” styles. The latter of these two styles allows parts to be sent upwards towards a bin or container.

Case Studies - Visit our website

We have provided on our website detailed information about several recent projects we have undertaken. These will give you a good picture of the diversity of our operations and the varied range of work we undertake. Included on the web page are outlines of several projects including the supply and installation of an interfloor fabric belt conveyor system; creating a bespoke gravity infeed and outfeed system; producing a highly effective twin chain conveyor installation and providing 24 VDC and lineshaft powered roller conveyor solutions.

Details

Info

| Registration Number: | 01180513 |

| VAT Number: | GB162 6815 57 |

| Registered at Companies House: | 12 August, 1974 (49 years and 8 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Brand & Trade Names

- Roll-EZY Ltd.

Products & Services

- Accumulating Conveyors

- Air Tube Conveyors

- Aluminium Conveyors

- Automated Conveyors

- Automated Systems Conveyors

- Belt Conveyors

- Belt Conveyors

- Brewery Conveyors

- Chain Conveyors

- Conveyor Accessories

- Conveyor Belt Drums

- Conveyor Belt Rollers

- Conveyor Belting

- Conveyor Belts

- Conveyor Components

- Conveyor Control Systems

- Conveyor Designers

- Conveyor Drive Components

- Conveyor Drive Units

- Conveyor Indexing

- Conveyor Installation, Maintenance, Repair

- Conveyor Rollers

- Conveyor Spares

- Conveyor Sprockets

- Conveyor Systems

- Conveyor Tracks

- Conveyor Wheels

- Conveyors

- Conveyors Uk

- Elevating Conveyors

- Flat Belt Conveyors

- Flexible Conveyors

- Flighted Conveyors

- Food Handling Conveyors

- Gravity Conveyors

- Gravity Conveyors

- Gravity Roller Conveyors

- Gravity Rollers

- Gravity Rollers

- Gravity Skatewheel Conveyors

- Heavy Duty Conveyors

- Heavy Duty Precision Link Conveyors

- Industrial Conveyors

- Industrial Turntables

- Interfloor Conveyors

- Line Shaft Conveyors

- Loading Conveyors

- Low Profile Conveyors

- Magnetic Conveyors

- Magnetic Conveyors

- Materials Handling

- Mild Steel Rollers

- Modular Conveyors

- Modular Link Belt Conveyors

- Modular Plastic Belt Conveyors

- Pallet Conveyors

- Pallet Handling Conveyors

- Pallet Rollers

- Pharmaceutical Conveyors

- Plastic Chain Conveyors

- Plastic Conveyor Boxes

- Plastic Conveyor Rollers

- Plastic Rollers

- Pneumatic Cap Conveyors

- Pneumatic Conveyors

- Pneumatic Tube Conveyors

- Polyurethane Rollers

- Portable Conveyors

- Powered Bends Conveyors

- Powered Roller Conveyors

- Roller Conveyors

- Rollers

- Rubber Conveyors

- Screw Conveyors

- Side Wall Conveyors

- Skip System Conveyors

- Slat Conveyors

- Small Conveyors

- Special Purpose Conveyors

- Spiral Conveyors

- Stainless Steel Conveyors

- Stainless Steel Rollers

- Steel Belt Conveyors

- Steel Rollers

- Table Top Precision Link Conveyors

- Tube Conveyors

- Unit Load Conveyors

- Zero Pressure Conveyors

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Liv Builders Ltd

- Link Hamson Ltd

- Jalaram Safe Deposit Lockers Ltd

- Street Lighting

- Alliance (London) Ltd

- HERITAGE CARS HARROGATE Ltd

- Resolute Developments Ltd

- Technical Report Writing Training

- LCD (Liquid Crystal Display) Daylight Viewable Display Screens

- Hrz Consultants Ltd

- Aluminium Sand Castings

- Carbon Fibre Rods

- Instrument Maintenance, Repair

- Companies beginning with M

- Affordable Housing 106 Ltd

- MOVIE WAVE PRODUCTIONS LTD

- Starfish Installations Ltd

- Richard Haworth Ltd

- Marilliam Flowers Ltd