- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

JBT

Overview

Products

We are one of the world's leading providers of technology solutions to high-value segments of the food processing and air transport industries, through our companies JBT FoodTech and JBT AeroTech. From our food processing solutions division JBT FoodTech, we offer an extensive variety of customised sophisticated industrial solutions for food processing. We design, build and service systems and equipment that provide solutions for: Freezing and refrigerating meat, poultry, seafood, fruits and vegetables, bakery products and ready-to-eat meals Processing protein including cutting and portioning, coating and cooking or frying meat, seafood, bakery products and vegetables Shelf-stable sterilisation for soups, sauces, fruits and vegetables, dairy products, ready-to-eat meals and pet food products Fruit processing including extraction, concentration and aseptic processing of tomatoes, citrus and other fruit We began developing innovative solutions to food processing requirements in 1884, when John Bean developed the first continuous spray pump to battle a scale that was affecting orchards in California, USA. Over the years, we have produced hundreds of innovations and we continually develop new equipment and systems that provide world-class solutions for today's global food processing requirements.

Applications

We provide productivity and quality solutions for dozens of food processing applications, including:

- Almond surface pasteurisation

- Baby food preparation, sterilisation, filling and closing

- Baked goods processing, proofing, chilling and freezing

- Dairy sterilisation, filling and closing

- Fish and Seafood refrigeration, processing, coating, cooking, filling and closing

- Fruit and vegetable preservation, processing, labelling, juicing, peeling, refrigeration and freezing

- Jam processing, filling and closing

- Meat and poultry portioning, coating, cooking and frying, refrigeration and freezing, filling and closing

- Pasta and Rice processing, steaming, chilling and IQF, filling, closing and sterilisation

- Pet food sterilisation, refrigeration, freezing, filling and closing

- Ready meals, sauces and soup processing, cooking, portioning, filling, chilling and freezing

Processes

We design and manufacture complete solutions for virtually all stages of value-added food processing, including:

- Filling and aseptic filling, including product preparation and pre-measurement and container sterilisation, filling and closing

- Metal can closing

- Fresh produce processing, such as post-harvest cleaning and fungicides, grading, decay management, protective coatings, labelling, filling and chilling, including tropical fruit, tomato and citrus juicing, peeling, production of essential oils, aseptic filling and waste peel disposal

- Food coating, including coating lines, breaders, batter mixers and applicators

- Cooking, including frying and extraction, linear and spiral ovens, grilling and charmarking, steaming

- Chilling and Freezing, including IQF, spiral, pellets and impingement freezing

- Pasteurisation and sterilisation

- Process and line control

- Slicing and proportioning

Products & Services

We offer an extensive range of equipment that provides solutions for every stage of food processing, such as:

- 5-Star Home-style Breader

- ADVANTEC Impingement Freezer

- All-Purpose Batter Applicator (APB)

- Apple Preparation System

- Aseptic Fillers

- Can Uprighter

- Citrus Aseptic Systems, Brush Washer, Beltroll Sizer, Concentrate Chopper, Finishers, Juice Extractor, POS Fresh’n’Squeeze Juicer, Produce Labellers, Quick Fibre Device, Citrus Roller Grader, Surge Bin and Cold Break Unit

- Closing Machines

- CM II Charmarker

- Corn Cutters

- Double D Continuous Baking Oven, Multi-Purpose Cooker, Rack Oven, Revoreel Baking Oven, Searer/Grill Marker, Steam Cooker, Wood Chip Smoke Generator

This is but a small sampling of the huge range of food processing equipment and solutions we

offer. Please visit our website for further information.

Tuna Processing

We have been a leader in the supply of tuna processing systems and equipment for four decades, with our in-house engineering and R&D staff working in cooperation with leading tuna processors.

Our tuna processing products include:

- Tuna Pre-Cooker for cooking under steam/vacuum/pressure and vacuum cooling

- Pre-Vacuumizing Tuna Oiler/Briner with two-phase fill cycle

- Tuna Fillers for high-speed filling of pre-cooked tuna into open-top cans

- Static Batch Retorts

- TunaCAL mathematical modelling software for improving yield and reducing cooking times and water consumption

SPACE Aseptic Fille

Our SPACE (Spout-less, Pouch, Automatic, Compact & Ecological) Aseptic Filler is our newest solution for aseptic filling.

- Spout-less: With removal of the spout from the pouches, the opening size is increased, enabling aseptic particulate filling as well as liquids.

- Pouch: Pouches ranging in size from three and 10 litres can be filled.

- Aseptic: Now Aseptic processing can be applied to institutional package sizes with significant package cost savings

- Compact: The SPACE Aseptic Filler’s aseptic zone is limited to the filling chamber, resulting in fewer critical control points, easier operation and minimal floor area.

- Ecological: Eliminating the spout results in reduced plastic packaging material, and the smaller

aseptic area reduces the volume of chemical disinfectant required.

READYGO™ Aseptic Monoblock

Our READYGO™ Aseptic Monoblocks, available in a range of capacities from 500 to 6000 kg/h, have been designed to provide high quality and aseptic reliability in small to medium size plant. Depending on the configuration, they provide aseptic filling of bags ranging from five to 200 litres.

READYGO™ Aseptic Monoblocks can process:

- Fruit purees (with or without pieces) and concentrated fruit purees

- Non-concentrated, semi-concentrated or concentrated tomato-based products

- Fruit dices

- Vegetable purees

- Juices: clear or cloudy; natural or concentrated

A wide range of other formulated products

The READYGO™ has a compact footprint, easy installation, and is flexible, reliable and user-friendly.

Knowledge

We have been developing food processing solutions for more than a century, and have built up an extensive amount of knowledge and experience during that time. We are happy to help our customers become more successful and profitable by sharing information on food safety, equipment and food

processing.

Our core competencies include:

- Chilling, Freezing and Refrigeration

- Citrus Extraction

- Coating

- Cooking, Frying and Filtration

- Filling and Closing

- Fresh Produce Preservation

- Labelling

- Portioning

- Sterilisation

We are members of CCFRA Group, EHEDG, AIJN, FPME and many other food safety and processing professional and research organisations.

Food Technology Centres

We have Food Technology Centres (FPTCs) in Europe, the USA and Brazil. The FPTCs offer a wide range of services, with experts who have access to application-specific processing data, thermal processing laboratory services and state-of-the-art equipment for production.Our specialists have conducted thousands of application tests, and continually conduct new tests,

such as cooking or freezing times, sterilisation, portioning, food quality and safety issues. Our mobile units carry out approximately 150 customer visits annually, and we offer over 100 training programs.

Aseptic Bag Fillers

JBT FoodTech FranRica Aseptic Bag Filling Systems provide packaging solutions for high and low acid food products such as tomato paste, vegetables and fruit, purees, particulates, concentrates, sauces, soups and dairy products. Our Aseptic Bag Fillers offer highly effective and reliable bag filling solutions. They are expertly designed and manufactured to allow uninterrupted operation throughout a complete tomato/ fruit season. At JBT FoodTech, we offer on site training for operators and maintenance and plant personnel can also be provided. Please contact us at JBT FoodTech for further information.

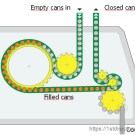

Can Uprighter

The JBT FoodTech Can Uprighter is a fantastic inline conveyor device that reorients cylindrical containers from a side position to an upright position. The container is rotated end-over-end while it continues to progress in a linear motion along the conveying system. The Can Uprighter system features functions with cans from 211 to 404 diameter at speeds ranging from 100-520cpm and functions with 603 x 700 cans at speeds up to 100 cpm. The system separates each container from a continuous stream of containers, creates a significant gap between each container and rotates the container at its centre of gravity to the upright position.Apple Preparation System

We are pleased to present the outstanding JBT C8-A Apple Preparation System. This is a first stage preparation system which has been expertly designed and created to peel, stem, core and slice apples. This system enables the production of quality products and keeps production costs to a minimum. This reliable system is manufactured from high quality materials in order to be tough and sturdy for long-term use. Please contact our specialists at JBT FoodTech for further information.

Citrus Aseptic Systems

With more than 100 years in the food processing industry we have the knowledge and expertise to create highly effective food processing solutions. More than 50% of the world’s in-container sterilised foods are filled, closed or sterilised using JBT FoodTech equipment. JBT FoodTech offers a range of Citrus Aseptic Systems such as: Aseptic Sterilisation Systems (including Tube-in-Shell Heat Exchangers for NFCOJ and Pulp), NFCOJ Deaeration Systems, NFCOJ Deoiler Systems, Aseptic Bag-in-drum and Bin Fillers, Aseptic Bulk Storage Systems, Aseptic Juice Blending and Flour Addition, and Aseptic Tanker Loading Systems.Citrus Beltroll Sizer

The JBT FoodTech Citrus Beltroll Sizer is widely used in the industry, favoured by its speed and accuracy. The Citrus Beltroll Sizer is manufactured from stainless steel and is designed to offer durability, accuracy, speed and versatility. It features a moveable frame and sizing rollers that can be raised or lowered easily via its motor-driven adjustment mechanism. The Citrus Beltroll Sizer also features: anti-friction ball bearings on all sizing rollers, wing diverter to prevent piggy backing, electric size adjustment that can be controlled remotely, idle drums constructed of wear resistant UHMW, and more. Please follow the link to our website to view images and detailed descriptions.

Citrus Juice Extractor

We are pleased to present the Citrus Juice Extractor – the world leading system in the citrus juice extraction market. Our Citrus Juice Extractor system processes 75% of the world’s juice production and is used in more than 35 countries. The extractor separates the juice from constituents which would have an adverse effect on the end product if left in contact with the juice for any amount of time. We also offer a Premium Juice Extractor (PJE) which has been specifically designed and created to reduce oil levels and bitterness in the juice.Cutters

Our JBT FoodTech Corn Cutters offer maximum product recovery, high throughput and require little maintenance. To complement our Corn Cutters we also offer a Factory Knife Sharpening Service as well as a Knife Honer service. Please contact us at JBT FoodTech for further information.

Double D Continuous Baking Oven

The Double D Continuous Baking Oven is a fantastic system designed for baking large volumes of morning rolls, quiches, pies, pizza, savouries, scones and pastry cases. The Double D bakes these foods to perfection. It uses a unique airflow system to create complete control over top and bottom heat resulting in excellent results. The Double D Continuous Baking Oven features a travelling band that can be custom-built to any required width, indirect, gas or oil fired and fan speed control and multi-zone control for increased flexibility.Tomato Scrubber

JBT Foodtech is pleased to supply the excellent Rubber Cord

Tomato Scrubber. This fantastic unit has been expertly designed and created to

remove peels quickly and accurately.

The system features an internal spiral that rotates to mix the tomatoes alongside rubber cords which remove the loose peels from the tomatoes. The speed of the rubber cord scrubber can be adjusted to suit differed types of produce. The produce is passed from the scrubbing phase through to the Pinch Bed.

The Rubber Cord Tomato Scrubber features easily removable

stainless steel doors with safety switches and stainless steel guards over

belts and sheaves.

Vacuum Filler

We are also pleased to supply the JBT Foodtech XL-Series

Vacuum Filler. This system removes entrapped air from containers that have been

filled with produce. The system is CE compliant and features large access

panels, grouped lubrication points, a sanitary design, stepless height

adjustment, large diameter infeed turret and safety guards.

Optional extras include: a sanitary base, automatic

lubrication, own drive, quick change parts, automatic fill volume adjustment,

synchronisation with closer and line control.

Please visit our website to find out more about the XL

series of vacuum fillers.

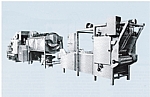

Sterilizers

Here at JBT, we have been setting the standard in the food

sterilisation industry since 1921 when we introduced our Continuous Pressure

Cooker and Cooler. Today, our sterilising equipment is used in a range of

industries around the world.

Our current range of sterilising equipment includes the

Continuous Rotary Steriliser and the JBT Foodtech LOG-TEC® Process Management

System which has been expertly designed and created to control all aspects of

the sterilisation process. This system enables users to create records in line

with FDA and USDA requirements.

Please visit our website to find out more.

Steam Water Spray

Our top quality Steam Water Spray system is HACCP compliant

and CE compliant. It is manufactured from high grade materials in order to be tough

and robust for heavy use and features a heat exchanger, insulation and

cladding, proportional control valves, micro cooling and LOG-TEC®.

Users of the Steam Water Spray benefit from a range of

functions such as process water pre-heat, ice water cooling, automatic door,

automatic basket transport, second door, future automation and basket tracking

system.

Please visit our website to find out more about the Steam

Water Spray system. Alternatively, please contact us directly at JBT Foodtech

with your requirements or for further information and we will be happy to help.

Details

Info

| Registration Number: | n/a |

| VAT Number: | n/a |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Brand & Trade Names

- 5-Star Breader

- ABC Mixer

- ADVANTEC™

- DHF Fryer

- Double D

- Double D Multi-Purpose Cooker

- Double D Revair Steam Cooker & Smoke Generator

- Double D Revoband Baking Oven

- Double D Revoband Continuous Protein Oven

- Double D Revorack Baking Oven

- Double D Searer/Grill-Marker

- Dry-Fry System

- DSI

- E Breader

- FA Fryer

- FLoFREEZE®

- FRIGoBELT®

- FRIGoDRIVE®

- FRIGOSCAN®

- Frigoscandia

- GCO Oven

- GYRoCOMPACT®

- GYRoSTACK®

- HPF Fryer

- JSO Oven

- LTS®

- LVS FRIGoPAK®

- LVS Refrigeration™

- M Fryer

- NAUTICA™

- PELLoFREEZE®

- ProMIX

- Stein

- Stein PRoGRILL

- SuperCONTACT®

- SuperFLOW®

- SuperTRAK®

- TFF Fryer

- Ultra-V Coating Equipment

- Water Jet Cutting

- XL Breader

Gallery

- THE JENNER COMPANY (LONDON) LTD

- THOMAS FORD CONSTRUCTION Ltd

- Orly Labs Ltd

- 43 Cambridge Road South Freehold Ltd

- Gerald Hallett Ltd

- LONDON

- Cambridge Sensotec Ltd

- Engineering Services

- Multi Monitor Display Screens

- To the Heart Ltd

- Cjp Research Ltd

- High Speed Centrifuges

- Deposition Services

- Gas Scrubbers

- JAMES FOX HOLDINGS LTD

- Aluminium Scaffolding Beams

- Stephanie's Cupcakes Ltd

- Vincent Young Consultancy Ltd

- Darren Brookfield Carpentry & Joinery Ltd