- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Hosokawa Micron Ltd

Overview

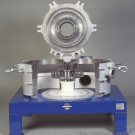

Products

Hosokawa Micron specialises in producing equipment for powder and particle processing, hygienic filling and weighing, as well as containment and plastic processing. We design, build, and install this range of equipment for clients across a wide range of industries. Our customers are situated in the UK and Ireland as well as a number of overseas countries. We can install small R&D commissions or full turnkey installations – backed by the global resources of our Japanese parent Hosokawa Group.

Industries – Agro-Chemicals

We design and manufacture equipment for the Agro-Chemicals industry with a special focus on size reduction features, separation of chemicals, air classification, mixing, conveying, product collection, and feeding. Agro-Chemical clients typically use these fathers for fertilisers, insecticides, and pesticides, as well as other uses.

Industries – Ceramics

The ceramics industry demands high fineness and high purity in its processing equipment. We are pleased to offer a wide range of heavy-duty products that can process very hard, high-tech ceramics of any kind for a maximum powder fineness. These systems are designed to reduce any risk of iron contamination; we have a range of linings available depending on the ceramic material characteristics. Please visit our website to inspect the huge range of products available for this industry.

Industries – Chemicals

Moderns chemicals processing equipment requires features designed with environmental protection in mind. The chemicals industry is required to meet high standards on emission rates and noise control. Chemical processing equipment also needs to protect against fires and explosions – flammable materials and dust building up are hazards. Hosokawa’s efforts to meet these needs means that our equipment conforms to all European regulations while offering excellent quality to our clients. Please visit our website to inspect the huge range of products available for this industry.

Industries – Cosmetics

Cosmetics manufacturing requires a huge range of base materials in a powder form. Product specifications, which vary endlessly in the industry, determine the machines used for their mixing. Hosokawa supplies complete solutions for formulating powdery cosmetics – from research to production. Talcum powder, eye shadow, and dental care products, are just some examples. Please visit our website to inspect the huge range of products available for this industry.

Industries – Food

Hosokawa has developed a range of processing systems to deal with the high quality grades demanded of food processing and production. We offer machines for highly automated food processing and manufacture. And all of our equipment conforms to GMP and FDA regulations for hygiene and sanitation. Our equipment can help with steam sterilisation and cryogenic grinding of spices, grinding cocoa powder from press cake and chocolate crumb, shifting protein in flour, sugar grinding, and pureeing vegetables and fruit. Please visit our website to inspect the huge range of products available for this industry.

Industries – Metals

Metal powders and powder fineness all demand a high level of purity and cleanliness. Hosokawa produces processing machines capable of recovering powders from the grinding process at maximum levels of purity. Metal oxides can be reduced to an ultra fine size, and our machines offer ultra fine sieving, air classification for deducting and other applications, as well as cleaning metallic alloys. Please visit our website to inspect the huge range of products available for this industry.

Industries – Minerals

Hosokawa offers a full processing system for producing mineral powders – while doing it reliably and at a low operational cost. The diversity of powder characteristics means that only our long experience and deep engineering knowledge can help clients handle phosphates, limestone, cement, calcium carbonates, and other minerals. Please visit our website to inspect the huge range of products available for this industry.

Industries – Pharmaceuticals

Pharmaceuticals, along with the food industry, has some of the highest safety standards of any industry. As such, the processing equipment used in the industry must also be at the highest standard. We offer a full range of services for process technology, machine design, and engineering, to meet the standards from the cGMP, GAMP, and the FDA. And we work with our clients to build systems for the high requirements of both primary and secondary production stages. Our containment solutions include isolator glove boxes, downflow, and laminator booths. Please visit our website to inspect the huge range of products available for this industry.

Industries – Pigments

Milling pigments demands that primary particles, which have been agglomerated together in the manufacturing process, are loosened up and then ground to a find powder. Deposits can form if pigments have not been properly loosened and ground. Hosokawa offers a range of products for all stages of pigment processing – from prebreaking to ultra fine milling and classification. We offer a full system for mineral colourants, black colourants, and dyes. Please visit our website to inspect the huge range of products available for this industry.

Industries – Plastics

Hosowaka offers a wide range of processing systems and products – including a drying system for highly engineered plastics as well as a high-performance recycling line for economical drying of production scrap – to meet the growing demand for processing equipment for plastics. We sell products that are easy to use, safe and reliable, and that do not take up inordinate space on a processing line. Please visit our website to inspect the huge range of products available for this industry.

Industries – Powder Coating

The powder coating industry is one of Hosokawa’s longest-standing and most significant areas of interest. We offer technologies and products for a broad range of applications in fine grinding work; and we are proud to say that no oversize particles can be expected in one pass of the processing offered by our equipment. Our particles can be ground to 15-35µ or even finer. We also offer laminar flow booths and fill/weigh systems. Please visit our website to inspect the huge range of products available for this industry.

Industries – Rubber

Hosokawa has a long history of supplying equipment to the rubber industry. Rubbers most often come in “bales” which then need to be reduced in size to facilitate blending or dissolving with other ingredients. We include granulators in our range of rubber processing equipment – ideal for granulating all kinds of synthetic and natural caoutchouc in bale or strip form. We also offer equipment for processing vulcanised and non-vulcanised rubber wastes. High impact polymers, butyrate’s, and nitriles, are all typical applications. Please visit our website to inspect the huge range of products available for this industry.

Industries – Soap and Detergent

We supply a range of processing equipment for the production of soap and detergent. This industry is characterised by a series of key processing operations – with the size and complexity of these operations varying from plant to plant. Hosokawa has designed and installed a number of production lines for soaps and detergents. We include as an essential features agglomeration and mixing technologies at the core of the processing operation. Please visit our website to inspect the huge range of products available for this industry.

Industries – Toner

Hosokawa offers processing equipment to deal with the raw materials that go into printer toner and that can handle the refined powder at the end of the process. Our equipment can help processing, from ultra fine size reduction, to classification, agglomeration, and mixing. Please visit our website to inspect the huge range of products available for this industry.

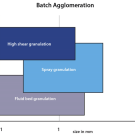

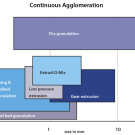

Technologies – Agglomeration and Compaction

Handling powders, dusts, and slurries, all pose significant processing challenges to industry. Our experience in agglomeration and compaction means that we can provide excellent technical and economical solutions for specific powder applications. We offer not just a machine but a set of engineering skills and systems capabilities to meet your needs. We rely on a range of technologies to address agglomeration requirements: from particle size enlargement, to compacting, to briquetting and pelletising, to extrusion technology, batch fluid bed processing, and others. Please visit our website to inspect the huge range of products that rely on these technologies.

Technologies – Air Classification

Advances in powder processing mean that modern production lines demand increasingly fine particles and narrower particle size distributions. Hosokawa have developed a range of classifiers to meet the different classification applications – in the pharmaceutical, chemical, and toner industries. Our classifiers are designed for easy use and maintenance; and they produce particle size distributions that are smooth, spherical, homogeneous, and easily dispersible. Please visit our website to inspect the huge range of products that rely on these technologies.

Technologies – Ancillaries

Hosokawa has developed a range of ancillary machines to supplement the features and processes used by our core products. These include a Ball Segment Valve, a Densepack, and a Rotary Valve. Please visit our website for more details on these supplemental products.

Technologies – Containment Technology

Containment and safety is a critical consideration across so many of our customers’ industries – from powder coating, to chemicals, to foodstuffs, to pharmaceuticals, to minerals, and so on. We produce a range of products for varying levels of product isolation and operator production. Our containment systems include filling and discharge systems, drum handling equipment, laminar booths, tipping booths, downflow booths, glove boxes, compact isolators, and other products and technologies. Please visit our website to inspect the huge range of products that rely on these technologies.

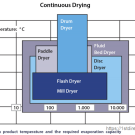

Technologies – Drying

Drying is as it sounds – moisture is removed from wet materials through evaporation by exposure to heat. Mixing and drying in fully enclosed operations is beneficial in all industries – transport conveyors are eliminated, as well as holding hoppers, and other ancillary tools. Downtime is reduced for cleaning and product loss is minimised. Hosokawa produces a range of technologies and products or continuous drying and cooling of a wide range of powders, pastes, slurries, and granules. Please visit our website to inspect the huge range of products that rely on these technologies.

Technologies – Filling and Weighing

Filling systems need to maintain accurate and weight-controlled requirements for the range of industrial applications expected by our customers. Hosokawa builds a range of filling and weighing products that adhere to the highest standards of dust control and hygiene. These technologies are suitable for drums, bags, and IBC systems; our products come with a wide range of filling and weighing choices. Please visit our website to inspect the huge range of products that rely on these technologies.

Technologies – Laboratory and Pilot Plant

Hosokawa offers as a special service a wide range of pilot and laboratory versions of its products specifically to help customers identify new solutions to the various problems encountered in different processing applications. Our longstanding commitment to research and development has led us to be engaged in this special sub-sector of the market. And Hosokawa works closely with its customers to take whatever solutions are identified with the laboratory and pilot plant systems and scale them up to production-sized equipment.

Technologies – Milling/Size Reduction

Powder processing involves a combination of raw materials, additives, and active ingredients; these are processed together to produce the required particle size of the powder in question. A wide range of specifications and requirements need to be met – from basic disagglomeration and coarse grinding through to ultra fine milling of particles to a sub-micron size. Our mill technologies, with special designs and various pilot or production sizes, are suitable for producing the broad variety of necessary powder types at various levels of fineness. Please visit our website to inspect the huge range of products that rely on these technologies.

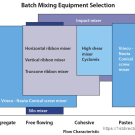

Technologies – Mixing

Hosokawa has long experience of mixing materials. The process and equipments used in materials mixing depends entirely on the materials due to be mixed. We have developed a range of mixing technologies suitable for both wet and dry powder applications. Our technologies and equipment cane supplied as either laboratory or pilot versions, or production versions, and we can meet any need for wet and dry powder mixing in both batch and continuous operations. Please visit our website to inspect the huge range of products that rely on these technologies.

Technologies – NanoPowder Technology

NanoPowder technology is a new and highly promising area of work for many industries – especially electronics, information technology, and healthcare. The possibility of a higher design effect at a much lower mass, as well as the promise of entirely new kinds of products achievable only with sub-micron particles, means that NanoPowder technology is a special area of focus for Hosokawa. The current applications for NanoPowder includes battery production, fuel cells, magnetics, toners, engineering polymers, cosmetics, drug delivery systems, food, recycling, functional films, catalysts, and electronics components. Our NaoPowder technology portfolio includes products with the latest advances in the field – promising added value with added functionality. Nanogrinding, measuring particle size, and downstream processing, are among the new technologies available in this area. Please visit our website to inspect the huge range of products that rely on these technologies.

Technologies – Screening

Our Tumbler screening machines are designed to meet the three-dimensional action needed and used in hand sieving. This fine-tuned approach allows Hosokawa to provide for a wide range of screen needs and sieving difficulties – for both wet and dry applications. These sensitive screens are used across many industries and are relied upon as robust all-purpose machines. Some of our models have up to five decks of screens. And we offer a number of screen cleaning options – from bouncing balls to ultrasonic cleaning.

Manuals & Brochures

Details

Info

| Registration Number: | 00823762 |

| VAT Number: | n/a |

| Registered at Companies House: | 19 October, 1964 (59 years and 6 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: |

Questions

Additional Information

Gallery

Financial Information

To view more detailed financial information for this company click here.

- LONDON

- RA CAR RENTAL LTD

- JT FOODS (LEEDS) LTD

- Caroline Susan Akello Ltd

- Cases

- K S International

- Dl It Management Ltd

- Ion Exchange Systems

- Lawson Financial Planning Ltd

- Identification Labels

- Ushtar Ltd

- Les & Lou Ltd

- C Bond Transport Ltd

- JAC CONCEPTS Ltd

- High Rise Recruitment Ltd

- Anchor Pumps Co. Ltd

- Synthetic Fibre Wadding

- ZERO JUICE LTD

- Roller Banners