- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Doncaster Laser Services Ltd

Overview

Notice: This company is listed at Companies House as 'Dissolved'

If you are aware of any more up-to-date details for this company please let us know here.

You can use the search box above to search for alternative suppliers

Products

We have been manufacturing quality laser cut components since 1997. As one of South Yorkshire's leading providers of advanced laser cutting solutions, we serve industries and clients ranging from fabrication and engineering to artists and architects. We combine modern machinery with a modern ethos; our attitude is "can do will do". Our aim is to take a partnership approach with our customers, providing a "Concept to Completion" service for bespoke parts by working with you from initial drawings through to a finished product that is entirely suited to your exact specifications. We work with a comprehensive range of non-ferrous and ferrous materials of varying finishes and thicknesses. We deliver throughout the UK and Europe, with a 24-hour production working day and 24-hour premium service turnaround.

Amada Press Brake

The Amada HFE M2 press brake has been designed for sheet bending and achieves this utilising a hydraulic ram. Users can produce a wide range of bend profiles thanks to the various distinct punch and die pairings available. The Amada press brake is not only easy to use but also reliable, versatile and suitable for a variety of different sheet bending applications. For further information on this or any of our products, please visit the website. If you would prefer to speak to someone directly, feel free to give us a call.

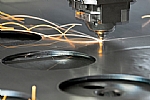

Laser Cutting Services

We can provide expert laser cutting services which can be used for both small and large scale projects. Utilising cutting edge software and technology, our engineers can provide services which are efficient, innovative and cost effective. It is also worth noting, that we strive to deliver high quality products and services within a convenient time frame. If you have any queries about our laser cutting services, you can contact our customer service team directly by phone or email and they will do everything they can to help.

Concept to Completion

Our “Concept to Completion” programme involves the creation, management and delivery of an integrated plan, from product inception right through to conclusion. This unique service covers every aspect of design and fabrication, as well as secondary operations, delivery, and any specific order details requested by the customer.

Just send us your plans or sketches, and we’ll put the project in motion. As part of our initial assessment we can help you with any technical aspects that need refining in order to improve feasibility. Whilst incorporating all of your design requirements, our experts will find a workable solution. And once you’re happy with it, we’ll get the project pushed through our Lean Manufacturing Operation.

If you’d like to discuss your plans with the Doncaster Laser Services team, please give us a call 01302 722215.

Benefits

The highly advanced laser cutting equipment in which we have invested gives us the ability to profile sheet metal efficiently, rapidly, and cost effectively. This results in a benefit to our clients because it enables us to competitively price our work and turn it around quickly, whether the requirement be for a one off prototype or for production quantities of parts or components.

Further benefits and features of using laser cutting technology include:

Latest generation software - Automatically positions different part profiles from different jobs on the same sheet, maximising sheet utilisation & reducing material waste as well as decreasing turnaround time by allowing us to cut more than one job at a time.

Auto Height Sensing - No marking of material is necessary.

Advanced Process Control - Automatically determines the exact position of the sheet on the laser bed, thus regulating the distance between the work piece and the cutting nozzle.

Auto Focus, positioning and dimensional accuracy.

High speed cutting with Nitrogen results in a more aesthetically pleasing finish with clean edges, only minimal discolouration and no oxide.

Finished parts can be marked for identification.

Industries Served

The benefits of laser machining are manifold and obvious, but speed, accuracy and cost-effectiveness are amongst the most prominent. With this in mind, it’s no real surprise that customers across a multitude of industries choose to use our services – after all, everyone appreciates high quality, low prices and fast turnaround.

We’re extremely proud to serve a number of important industrial sectors, all of which benefit from the bespoke design and fabrication solutions that we provide. They include aerospace, architectural, nuclear, agricultural, petro-chemical, railways, electronics, motor sports, defence, marine and many more.

Bespoke Solutions

Our flexible approach to design and fabrication allows us to produce high quality bespoke components in exact accordance with customer specification. We give you total control over the choice of material, features and fixtures, and in most cases the way in which the item is made. Our team keeps you involved throughout the design process, so that you always know what’s going on, and so that your input is always taken on board. And while we do everything we can to make the project as feasible as possible, we’ll always find a way of incorporating your design ideas, one way or another.

Volumes are also highly flexible, from one-offs to 1000+ batches, and we’ll keep all the records in case you would like to make a future order.

Facilities

Over the years, Doncaster Laser Services has invested heavily in its machinery and plant personnel. And, so that we continue to remain a cut above the rest, we’ll keep doing so. The net result is even greater quality, speed and cost-effectiveness for our customers.

With expert engineers and state-of-the-art machinery at our disposal, we’re able to offer a range of sub-contract services that exceed all expectations – from bending, drilling and taping, to rolling, welding and general fabrication. And by working closely with approved industry suppliers, we can also source and manage mechanical polishing, water-jet cutting and pickling and oiling services.

Machinery

Our machinery represents the very latest in laser technology, with systems from Trumpf, Balliu, Bystonic and LVD all present in our Yorkshire-based manufacturing facility. And with bed sizes ranging from 3 x 1.5 to 4 x 2, we’re able to process components large and small.

With these systems in place we can work with a number of materials, including mild steel (up to 20mm thick), stainless steel (up to 10mm thick), aluminium (up to 6mm thick), titanium, zintec, spring steel and tool steel.

LVD Axcel 3015

Our objective is to provide you with a professional, expert service tailored to the delivery and timescales of your requirements. We can usually deliver smaller projects within 3 to 4 days, while large scale projects are provided with key delivery milestones.

We use the latest laser cutting technology, with five laser machines including our new state-of-the-art LVD Axcel 3015 laser machine that enables us to cut materials to extremely fine widths and produce a wide variety of definitions and shapes.

The LVD Axcel 3015 has automatic sheet loading and unloading, a large sheet size, fast moves and a high cutting speed. Its positioning accuracy is 0.05mm with repeatability within 0.02mm.

Capabilities

We offer full laser profiling services, from initial concept to project completion.

We can work with a variety of materials and thicknesses. Our cutting capacities include aluminium up to 6 mm, stainless steel up to 10 mm, and mild steel up to 20 mm.

Download Brochure

If you would like to find out more about Doncaster Laser Services, please head directly to our website, where you can download our brochure in PDF format. And if you have a project in mind that you want to discuss in detail, please do not hesitate to get in touch. Our experts are on hand to help turn your ideas into reality.

Details

Info

| Registration Number: | 07493226 |

| VAT Number: | GB695 1841 02 |

| Registered at Companies House: | 14 January, 2011 (13 years and 3 months ago) |

| No of Employees: | 11-20 |

| Annual Turnover: | 1-2m |

| Importers: | |

| Exporters: | |

| Company Type: |

|

| UK Branches: | PRC UK Ltd |

Questions

Additional Information

Brand & Trade Names

- PRC Laser Supplier of a wide range of CO2 lasers from 1 kW to 6 kW

Company Certifications

| ISO/TS 9002:2016 - Quality management systems – Guidelines for the application of ISO 9001:2015 |

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Torque Tightening Tools

- Afobi Ltd

- Super Duplex Forgings

- Winter Investments Ltd

- Hancock Installations Ltd

- The Wash Shop (UK) Ltd

- Competent Security Ltd

- Reduced Energy Cables

- Bjoerklund Invest Ltd

- Anti-collapse Mesh

- Wedges

- Tinware

- Bsr (Wigan) Ltd

- Ron Lee Ltd

- Adrian Hornsey Ltd

- Corrugated Tubes

- EINSTEIN MARKETER Ltd

- Gillo Interactive Ltd

- Companies beginning with T