- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Specialist Tooling Technologies Ltd

Overview

Products

Specialist Tooling Technologies Ltd is a renowned company that provides manufacturing and measurement solutions to clients in a range of industries. The company is owned and run by experienced engineers whose combined knowledge and expertise enables them to provide first class solutions to all kinds of problems and requests. We are approved to BS EN ISO 9001 2000 standards and are dedicated to providing customers with a reliable service of the highest quality. Our expertise and services largely fall into the following categories: Tool-making, Inspection and Measurement, Aerosol Gauging, Special Purpose Machines, Engineering Services, and Software. We are pleased to have the capabilities and facilities to meet small one-off demands through to regular, large batch requests. We are able to provide complete project management services from design stages through to prototype, testing and production. Please visit our website to find out more about our range of services, or call our friendly team at Specialist Tooling Technologies Ltd for further advice and information regarding the services and solutions we offer.

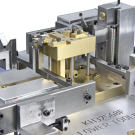

Tool Making

We use a range of state of the art equipment to create high quality products. Examples of equipment include CNC Holding Fixtures - these enable our engineers to hold and work with awkwardly shaped components on CNC machining centres. These holding fixtures can be manual, pneumatic or hydraulic clamping depending on the requirements of the job. We also work with Cube Mounted CNC Machining Fixtures to enable multi loading and indexing capabilities for CNC machining. Our Fourth Axis CNC Machining Fixture enables the fixture to be mounted between a fourth axis indexing unit and a tailstock with hydraulic locking sleeve for maximum rigidity during machining. We also design and manufacture various fixing systems, gauges and test rigs for use in the railway industry.

Inspection & Measurement

It is essential that all equipment is inspected and tested for safety purposes and to meet the relevant industry requirements. In order to do this we use a range of machinery and equipment to carry out inspection and measurement processes effectively and accurately. Examples of the equipment and processes used includes: Crimp and depth diameter gauges for use in aerosol manufacture, 36 Point Universal Gauging M/C for turbine blade measurement, Fan Blade Gauging for use in the aerospace industry, Profile Gauging for radial grinding of aerofoil segments, Semi-Auto Multi-Point Gauging Turbine Blade Inspection, Acceptance Gauges, 5 Axis Positioning of turbine blade for X-ray inspection for use in a range of industries, and more.

Engineering Services

We provide customers with a spares and consumables service to provide security in the event of a breakdown. We work with individual clients to create a spares/consumables list and manufacture a quantity higher than that initially required. We hold the excess in stock ready for the client to request in the event of a breakdown or for regular maintenance and repairs. This process provides clients with spares and consumables in fast turn-around times when needed. We also carry out emergency repairs when required. We work quickly and efficiently to fix/solve problems and will also provide advice and information on services that may prevent similar breakdowns occurring in the future. We have a great reputation for our ability to provide innovative problem solving solutions. Please contact us with your enquiries.

Software

We are pleased to provide clients with specific software solutions that are created to provide all of the features that are required for the effective running of various processes. Our software solutions can be as simple or as complex as you need them to be and we work closely with you to gain a firm understanding of what is required. Our bespoke solutions are tailored to provide cost-effective solutions and can be in the form of standalone projects, networked, integrated with existing systems, or supported via the internet. Please contact us with your requirements and to find out more about our software solutions.

Special Purpose Machines

We stock three types of special purpose machines that can be incorporated into your manufacturing process for a variety of different functions.

The Hole Coding machine can punch a permutation of any nine holes - pre-programmed in a PLC - in an aluminium pressing for part identification, by inputting the part number on a key pad. The machine also incorporates a stamping operation which marks each component with a serial number.

Dispensing machines are pneumatically powered, adjustable for component width, are PLC controlled and start and stop dispensing bead of oil into a groove by optically sensing the position of each end of the component allowing any length of component to be filled with no set-up time.

Radiator Pre-weld Jigging machines are pneumatically controlled and powered and pre-clamps aluminium radiator cores prior to welding, making it applicable to other assemblies that require preparation prior to welding.

Aerosol Equipment

We sell weight types of aerosol equipment – from crimp gauges to manual capping machines for prototyping, laboratories, and production.

The Crimp and Depth Diameter Gauge reduces aerosol production costs by monitoring the quality of crimps and processes. The Manual Capping Machine is used especially in laboratories and prototyping to place caps on cans in low-volume production. The Cap Actuator Cycle Test examines the life cycles of cap actuators. The Valve Diameter and Stem Height Gauge measures the diameter of valves and steam heights to track consistency across a production line. The Can Stability Gauge checks that each can on a line is evenly balanced and eliminates misshapen cans. The Ecogorge Gauge carries out a dimensional inspection of an aerosol can to make sure the product is properly manufactured. The Radial Can Cutter allows you to sample a large number of sizes in a pre-production test run. And the Impact Test Rig checks for resilience in your aerosol can production.

Aerospace Tooling

We sell a range of specialist aerospace gauging fixtures and work holding equipment – including electronic gauging with dedicated software.

The Multi-Point aerofoil inspection gauge are the quickest and surest way to inspect blades: repeatable, accurate, robust and fast. We also have holding and acceptance fixtures for blade machining and gauging – making sure that a blade is properly machined and then accurately checked for its alignment. And the Blade Chorch and Annulus Gauge is a 56-point manually loaded and clamped, pneumatically activated, fast-acting gauge for the workshop.

Vision Systems

We offer a range of Vision Systems – inspection systems – for inspecting produced parts and products. The in-line inspection camera is used to track strips of metal moving at high speed. We also sell products for dimensional and electrical continuity testing of parts – including a system to check part integrity. And we offer a system for dimensional checking of pressed parts through software; this system checks small pressings in any orientation. Please visit our website for more details.

Data Logging & SPC Software

Standard software programs are designed to appeal to a large section of consumers and can often focus more on breadth rather than depth. It is for this reason that we offer completely bespoke software packages which are designed with your specific requirements in mind. Furthermore, all of our specialist software programs are simple to install and use and offer excellent value for money. If you have any queries about this or any of our products feel free to visit the website or you can contact our customer service team.

Workholding

We stock a wide range of workholding equipment, including CNC holding fixtures, cube mounted CNC machining fixtures, fourth axis CNC machining fixtures and fixing systems. We understand the importance of versatility and it's for this reason that some of our workholding products have the option of hydraulic and manual clamping. To find out more, don't hesitate to visit the website or you can contact us directly, by phone or email.

Details

Info

| Registration Number: | 04912170 |

| VAT Number: | n/a |

| Registered at Companies House: | 25 September, 2003 (20 years and 7 months ago) |

| No of Employees: | 11-20 |

| Annual Turnover: | 1-2m |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Questions

Additional Information

Company Certifications

| ISO 9001:2015 - Quality management systems – Requirements |

Gallery

Financial Information

To view more detailed financial information for this company click here.

- THAAT Ltd

- Cherry-c Ltd

- Interlocked Machine Covers, Guards

- Waggon & Horses Inn Ltd

- Piston Pumps

- Carton Sealing Tape

- Active Lec Ltd

- Vehicle Noise Control Solutions

- Adeiladwyr D & S Jones Builders Ltd

- Spamco Ltd

- Companies beginning with M

- Instant Promotion (UK) Ltd

- EVENT HIRE BOUTIQUE LTD

- CURRY POT INDIAN CAFE Ltd

- John Andersen Support Services Ltd

- Hollow Shaft Encoders

- Blinds

- Delkim Ltd

- Chinese Mouldmaking