- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

Schaublin Machine Tools Ltd

Overview

Products

Anyone working in an industry which relies on

precision milling and turning will be familiar with the name of renowned Swiss

manufacturer Schaublin Machines. As their nominated

supplier in the UK, Schaublin Machine Tools Ltd provide the finest CNC lathes,

CNC machining centres, conventional lathes and micro lathes to customers at

home and in Ireland.

Whether

your operation requires hard turning, autoloading, milling or bar turning, our

machine tools have long set the standard in our sector. From the moment you

first contact Schaublin Machine Tools Ltd in our

Winchester base, we’ll offer the highest quality information and technical

support. Our expert engineers will

consider the details of your brief and produce the most appropriate solution

for your particular requirements. We’ll tell you how you can shorten production

cycles and thereby reduce costs, while simultaneously advising you on the best

tools and production techniques. After studying your component diagrams, we’ll

come up with an itemised production schedule. If you wish, our staff can also train

you on how to use your accessories and machine tools.

If

you’re not sure what the correct machine tool choice is for your enterprise,

just phone or email us. It’ll be our pleasure to point you in the right

direction!

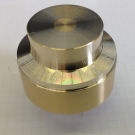

Micro Lathe - 70 CF

Our high-precision bench-mounted 70 CF micro lathe operates on a W12 Collet system and has programmable spindle RP. Its cabinet tooling draw pack is fully integrated, while its programmable frequency convertor will allow you to pre-set as many as four spindle speeds. The lathe’s tailstock is screw operated, while the possible range of attachments include a dividing headpiece fitted with perforated discs; a milling attachment functioning at 10,000 RPM; a grinding attachment with an RPM of 30,000; a fast-closing attachment operated by lever; and a fixed steady. The machine’s floor-space dimensions are 1,600 x 800mm and it weighs 250kg.

Micro Lathe - 102 N-CF

The 102 N-CF micro lathe is perfect for toolroom machining and for research and development. Highly innovative, this high-precision product features a belt-driven spindle and comes with a cabinet tooling draw pack. You can set a maximum of four spindle speeds in advance, and the Morse 2 tailstock is operated by screw. The milling attachment performs in the range 600 to 9,000 RPM while the grinding attachment operates between 4,000 and 24,000 RPM. Choose between a W20 and W25 collet system, while a vacuum clamping system is an additional option. The height of the 102 N-CF is 200mm and the resolution Z axis is 0.01mm.Conversational Programming Lathes - 125 CCN series

The lathes in the 125 CCN series feature every attribute of conventional lathes as well as the extra advantages of CNC. They are perfect for such applications as one-off prototyping and producing medium-sized batches. They employ either ISO programming or conversational cycles. The variation in the spindle nose is what decides useable bar capacities. These machines augment machining parameters by offering 6, 8 or 12 stations turrets which make driven tooling an option when carrying out milling on R-TM models. Programming is enabled through a Fanuc Oi Mate TD CNC control, and lathes have a full range of accessories and attachments available.

CNC Lathe - 102 TM CNC

Schaublin Machines’ 102TM range of CNC turning machines have been created as basic level 3 axis CNC lathes, enhanced by the incorporation of driven tooling options and standard rotary C axes. Thanks to the inclusion of the Fanuc Turn Mate, they need no prior ISO programming experience. Easy-to-use conversational cycles make generating part programs simple, while six-station turret options broaden the choice of machining parameters. The 102TM lathes have a spindle motor power of 1.5 kW and their maximum diameter is 200mm. Each machine has an integrated two-drawer tooling cabinet, a linear tooling system and five frontal toolholders.

CNC Lathe - 225 TM CNC

The robust 225 TM collection of CNC lathes are ideal for those using CNC for the first time. They’re suitable for any industry manufacturing in small batches or undertaking prototype machining, and are for hard-metal machining at a level of 65Hrc. Spindle stops and attachments for milling and grinding are complemented by screw-operated tailstocks. The use of the Fanuc Oi Mate TD CNC control gives ultimate flexibility to the operator. A large range of work holding is offered, and spindle speed is between 50 and 5,000 RPM. Maximum turning length of the 225 TM lathes is 409mm and each machine has two radial toolholders.

Turn/Mill Centre - 136 4AX

Turn/mill centres are a great choice for organisations needing to achieve high rates of precision, reliability and repeatability. The 136 4AX type employs a refrigerated 12-point glycol water cooling system which sends recirculated liquid around the machine to provide thermal stabilisation. A 23kw motor spindle powers the main spindle and the centre’s driven tooling works at 12,000 RPM. Boasting feed rates of 40 m/min and acceleration greater than 0.5 G, this model weighs five tonnes and has a C axis with positioning of 0.001 degree and accuracy of ± 4 arc seconds. The spindle throughbore is 36mm long and its motorpower is 23 kW.Turn /Mill Centre - 142 11AX-Y

If you’re producing highly complex components which require the finest grade of precision, consider the 142 11AX-Y turn/mill centres. They all have bar capacities of 42mm, and their identical twin turrets have 12/12 tooling positions. The centres feature Fanuc 31i A CNC digital drives and controls while their Y axes are ± 43mm. Their repositioning toolbars offer very high precision, at 0.002mm, and the sophisticated cooling system successfully avoids non-mastered dilatation. Twin spindles work at 23kW to provide power to the main and counter spindles. The 142 11AX-Y centres have up to 24 possible driven tools and their X1 upper turrets give 181mm axis strokes.

Machining Centre - 160 CNC Fanuc

The vertical machine centres in the Schaublin Machines stable have a well-deserved reputation for delivering precise production in industries from oil and gas to micro-machining. They’re built in heavy-duty cast iron and have an exceptionally speedy traverse of 36 metres per minute as well as 30-position toolholder drums. The fast acceleration and deceleration of axes and spindles help reduce time spent not cutting, with all axes possessing a repeatability accuracy of 0.002mm. Optional features include Lehmann rotary fourth/fifth axes, Renishaw tool and workpiece measurement probes, and spindle coolants to raise pressure levels.Machining Centre - 51 5AX-12K

Among the gems of our 51 5AX series of machine centres is the 51 5AX-12K, which is to be found in the medical, Formula 1 and aerospace sectors. This five-axis powerhouse has a mighty Heidenhain iTNC 530 CNC control and 35mm-wide linear guideways of a roller design comprised within the X, Y and Z axes. Consequently, the machine is particularly rigid and stable and is able to achieve a traverse federate of 30m per minute. Sturdy tilting and rotary axes give greater accuracy in the process of simultaneous interpolation, and every axis has repeatability accuracy of 0.004mm.

Details

Info

| Registration Number: | 06407313 |

| VAT Number: | n/a |

| Registered at Companies House: | 23 October, 2007 (16 years and 6 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Importers: | |

| Exporters: |

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Mini Excavators

- Maple Scaffolding Bath Ltd

- Devine Management Consultancy Ltd

- Analytix Ltd

- A Plus Property Services Ltd

- Stress Corrosion Cracking

- Bookschoolcover.com Ltd

- Eastfield Media Ltd

- Plastic Polycarbonate Packaging

- Companies beginning with M

- Carbon Nitrogen Analysis Equipment

- Asm Commercial Cleaning Ltd

- Signs

- Homecheck Survey Ltd

- Everify Management Group Ltd

- Heviso Ltd

- Clerical & Domestic Services Ltd

- Fidus Power Ltd

- Dealerworld Ltd