- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

NUM (UK) Ltd

Overview

Products

We offer complete CNC machine automation solutions, with expertise in tool grinding, transfer and multispindle machines, HSC and 5-axis machining, wood processing technology, gear hobbing, general purpose and cutting machines. Based in Coventry, with offices around the world, we have the engineering experience to take on a wide range of projects and design bespoke solutions. We can ensure all your automated parts work together efficiently, making your daily production profitable with our hardware and software range.

Our project management makes the whole processing easier, with co-ordination and co-operation helping to optimise your application. We work closely with your own development teams, combining knowledge and collaborating on projects. We even take on responsibility for full implementation, including development and commissioning, and training with full support service. Our work has taken us across cultural and national borders, allowing us to act as your partner from the initial ideas through to realisation and customer service. We also offer a comprehensive guarantee for up to 30 months for Original Equipment Manufacturers (OEMs), ensuring that spare parts are always close at hand and downtime is reduced.

We were developing the first CNC controller back in 1961, and since then have constantly been seeking to improve and offer better products to our clients. With an excellent track record of working in various niche markets, you can trust our years of expertise when it comes to handling your project.

New CNC System Flexium+

The new Flexium+ system gives a new level of state of the art functionality with brand new hardware and software platforms with enhanced features and performance. We have built on the success of the Flexium range which already had over 10,000 applications, scalability, flexibility, and unique CNC functions, and added enhanced features, new panels, and an enhanced servo bus. With compact CNC dimensions that limit the energy requirements, the Flexium+ uses latest generation processors, along with intelligent hardware, to ensure a long system life and an excellent return on your investment.

Operating Panels

Our operating panels can be integrated with your PC, or used in operation with an external computer. The nPad is a small handheld terminal, and is available with a wireless version, and our FS152i and FS192i control panels give a large range of different performance classes. The Axium Power CNC can take on the toughest applications, offering flexibility, precision, and productivity with industry specific functions that can be customised for most requirements. Or choose the NUMPower for a complete, compact solution for 2- to 32- axes machines, with intuitive and simple operation.

Innovative Servomotors

We have recently launched two brushless servomotor ranged for CNC machines, which eliminate the need for a separate encoder cable. This allows for a single drive to motor cable, making installation quicker and improving system performance. With a range of output power, sizes, and speed ratings to match your application. The SHX range is great for cost-effective applications and has models available for continuous torque outputs. For high-end machine tools and other demanding power-to-volume ratios, the SPX range offers a high degree of protection for robotics, grinding machines, and many other applications.

Project Management

We offer a comprehensive project management service, aiming to achieve the best results for your business and its needs. Our main goal is to integrate ourselves with your in-house team, ensuring we know exactly how your processes work and all about your company's culture. It doesn't matter where in the world you are, we have branches around the globe and have worked with businesses of all kinds. Your developers work with our experts in automation to create the product that will work for your company, ensuring that all your needs are taken into consideration.

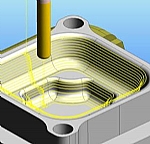

NUMROTO Overview

NUMROTO is used in tool production and reshaping in over 40 different machines from 15 well respected manufacturers. This allows the NUMROTO software to be used in the machine that suits your needs, and it can be easily networked to your in-house surgery. 2D and 3D simulation allows you to see an animation of the grinding process and collision monitoring, allowing a complete preview of the finished tool. The interface is based on Windows standard, making it easy to operate and train your staff on.

NUMtransfer

We have supplied CNC systems for many years, and the NUMtransfer series offers a complete solution for operating transfer, rotatory transfer, and multispindle machines. NUMtransfer is adaptable to all machines, and the user interface can easily be adapted to suit your needs. With special CAM functions and the ability to easily set up the machine for small batches, NUMtransfer can make your process more cost effective and ensure you can provide flexibility for your customers. The multi-CNC operation allows you to control any number of axes or stations, as well as assignment or switchover of C-axis to various axis groups.

NUMhsc

We have supplied CNC systems for many years, and the NUMtransfer series offers a complete solution for operating transfer, rotatory transfer, and multispindle machines. NUMtransfer is adaptable to all machines, and the user interface can easily be adapted to suit your needs. With special CAM functions and the ability to easily set up the machine for small batches, NUMtransfer can make your process more cost effective and ensure you can provide flexibility for your customers. The multi-CNC operation allows you to control any number of axes or stations, as well as assignment or switchover of C-axis to various axis groups.

NUMwood

We have worked with CNC technology in the wood processing sector for over 30 years, and we have the innovation to work with individual machines or in production lines. Whether your business manufacturers furniture, kitchens, doors, staircases, skis, or specialist items, we make it easy for facilities that use continuous feed technology to use the same technology as stationary processing centres, reducing retooling times. Many businesses that deal with wood processing have custom machines, and therefore have specialist needs. We have the skills to work with your automated system, whatever the application.

NUMgear

NUMgear offers a clear, user friendly interface for gear hobbing, and can be used in combination with our high performance hardware. This includes a fully integrated drive with automatic alignment of the spindle and tools, and many other useful functions. NUMgear has the added advantage of being easily retrofitted to older machines, and even usual models, offering new efficiency to your machine.

NUMspecial

NUMspecial allows the automation of general purpose machines, ensuring they are stable, compatible, and expendable. Our team can help you achieve a system with high performance machines, working with your own developers to create a truly bespoke system. NUM special is an open system, allowing for expandable and adaptable automation systems.

NUMcut

If you have a system with three or more axes, NUMcut can help turn your 2D machine into a 3D system, including applications that use plasma, laser, or water jet cutting. Offering an angled cut feature, which compensates for the shape of plasma or water jet, and NUMcut makes it easier to make high precision cuts. Our 5-axis head offers considerable technical advantages, giving both rigidity and flexibility of movement needed for 3D cutting.

CNC Competence

Because of the openness of NUM CNC systems, we can easily help add innovations to your everyday processing functions. This opens the field for developing unique selling points, and to encourage these innovations, we provide the development tools, create special functions, and help businesses put them into operation. Our user interfaces are written in HTML and Java Script, making them easy to modify using widely available software, and structured programming makes it easy to read data and change cycles.

HMI Examples

Our HMI software for NUM CNC systems can be used for a wide range of machines, and with 3D simulation, ensures the operator can see what's going on at all times. Being able to control complex machines is essential in a modern manufacturing environment, and our software offers standardised server functions that can be adapted by the customer or by NUM. With easy operation, training of staff is simple, and the user friendly interface can be adjusted to suit your specific application.

CNC Controls

The Flexium CNC is at the heart of many of our solutions and systems, offering a compact design with low power consumption and lower heat radiation. However, the Flexium still manages to offer high computing speed thanks to its powerful processors, and the newly designed development environment provides many new tools for integrating it into your system. Programmable for more than 200 axes over 40 channels, there's plenty of memory for even the most demanding applications.

Drives

NUMDrive servodrives work with the Flexium CNC to deliver high levels of precision, high power density, and low power consumption. Offering a massive level of computing and drive power in a compact space, our drives have some of the best power/space ratios on the market. With scalable control units available in single or dual axis, it's easy to find the most economic solution for your needs, and these drives can easily be adapted to suit your machines and applications. We also offer a range of safety solutions which can be easily implemented to the NUMDrive X, allowing important functions to be installed easily and without lots of additional wiring.

NUM-Service

We are proud to offer complete consultation and support throughout the life cycle of your product, whether it's start up and testing, project development, or upgrade and evolution, we work in partnership with your development team to ensure you are reaching your full potential. Our service concept has five main pillars: training and support, maintenance and audits to ensure things are running smoothly, repairs and upgrades to keep you ahead of the competition and reduce downtime, proactive replacement programs, and modernisation and maintenance of value. We believe that this service helps you keep at the peak of productivity, no matter where you are in the world, and we aim to be there before any problems arise, hence our motto: “one step ahead”.

Details

Info

| Registration Number: | n/a |

| VAT Number: | GB478 4976 73 |

| Founded: | 1 January, 1987 (37 years and 5 months ago) |

| No of Employees: | 1-10 |

| Annual Turnover: | 1-2m |

| Parent Company: | Num AG |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 05:30 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Brand & Trade Names

- MNDA Mono Drive

- Num CNC, Servo & Spindle Drive

- servomac Servo & Spindle Drives

Gallery

- Nutrition Lifestyle Ltd

- Trobridge Court Management Ltd

- Sussex Auto Trader Ltd

- Absorice Ltd

- Hazardous Area Isolators

- Wire Butt Welding Plant & Equipment

- Central Service Developers Ltd

- Surface Hardening

- Hydro-Cleansing Ltd

- ESTEBAN SERVICES Ltd

- ARUNDEL ESTATES Ltd

- Corporate Gifts

- Flushing Valves

- J E Stutley Ltd

- Naked Telecom Ltd

- Mining Industry Consultants

- Postcodes beginning with PR

- Victoria Sian Ltd

- Training Assessment Safety Consultants Ltd