- 60,000 contract/tender opportunities per year

- 4 Million UK Companies listed

- 12 million Director Names

- 100 million web pages indexed

FTL Technology

Overview

- Mr Darren Thomas - Sales Manager (Pumps & Valves)

- Mr Jamie Hill - Sales Manager (Oil & Gas)

- Mr Richard Ford - Sales Manager (Heavy Industry)

- HEWITT, Andrew John - Director

Products

Based in Leeds, FTL Seals Technology Ltd are experts within the design and manufacture of sealing systems. We are incredibly proud to have the position we do within the industry and we have achieved this through hard work, dedication and excellent customer service. We also understand the importance of providing products which are not only effective but also completely tailored to the job at hand. It is for this reason that we offer both standard sealing systems as well as completely bespoke alternatives. Furthermore, our team of engineers strive to develop newer and more advanced technologies every day in order to provide solutions for problems within a wide range of industries. It is worth noting that we can offer a complete consultancy service which includes advice on design, manufacture and installation, and everything in between.

If you have any problems or you would like to discuss your options further, please feel free to contact our customer service team by phone or email and they will do everything they can to help. It is also worth visiting the website for more detailed information on all of our products and services.

Rodas Ram

The Rodas Ram is a cylinder component which has been designed for use within Babcock 'E' type mills. This device is an oil free system which utilises nitrogen and can be used in place of the traditional pneumatic/hydraulic cylinders. With a service life of 30,000 hours, the Rodas Ram benefits from low maintenance costs, low repair cost and an environmentally friendly design. To find out more, don’t hesitate to visit the website or you can contact us directly.

Central Tyre Inflation

Our central tyre inflation services can be used for a variety of different vehicles, including defence, road and agricultural based vehicles. The inflation technology allows drivers to control the pressure within the tyres, without having to stop the vehicle. This service is especially useful for those who are travelling across uneven or even dangerous terrain. If you would like to find out more about this or any of our products and services please visit the website.

PTFE Seals

We have many years of experience working with PTFE components and can offer a variety of different compounds, to suit specific requirements. Our PTFE seals can be utilised for different applications, including rod seals, rotary shaft seals, piston rings and spring energised seals. With a high chemical resistance, a broad operational temperature range and a low coefficient of friction, out PTFE seals can offer excellent performance across a wide range of environments.

Hydraulic Seals

We can provide a comprehensive selection of hydraulic seals made from materials including FKM, PUR, NBR and filled PTFE. We have the experience and resources to offer hydraulic seals which are not only effective and reliable but also completely tailored to the job at hand. Our seals have been designed for use with high temperature and high pressure applications such as within construction equipment, agricultural machinery and extrusion presses. To find out more, feel free to visit the website.

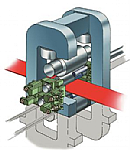

Mechanical Face Seal

Our range of mechanical face seals can be fitted onto a variety of different machines. The seals themselves feature an innovative design which makes them ideal for environments with high contamination, for example those around sand, mud and water. It is also worth noting that our mechanical face seals are hard wearing and corrosion resistant in order to guarantee a long lifespan. Just some of the equipment that our seals can be utilised with include, military drivelines, turbines, pumps, tracked undercarriages and mining machinery, as well as many more.

Heavy Duty Rotary Seals

For many years we have supplied heavy duty rotary seals to a range of different industries including the paper, power, marine and steel sectors. As well as offering standard products, we can work closely with our clients to provide completely bespoke seals which take specific requirements into account. It is also worth noting that our components can actually improve the performance and reliability of your existing machinery. To find out more, feel free to visit the website.

MECO Seals

MECO seals are designed for very specific applications were other components have failed, one such application being process machinery. It is worth nothing that our MECO seals can work with a range of different material types including slurries, pastes, fluids, vapours, gases and powders. Just some of the advantages of utilising MECO seals include reduced maintenance costs, the ability to work with abrasive materials and the peace of mind of using products which are ATEX and FDA approved.

Shaft Seals

Our PTFE shaft seals feature a unique design which allows them to operate in particularly harsh environments where elastomer components wouldn't be suitable. Just some of the benefits of our shaft seals include chemical resistance, excellent wear resistance, and the ability to operate within a broad temperature range and anti-adhesive characteristics, as well as many more. Users can utilise our shaft seals for a wide range of applications, including dosing systems, rotary compressors and centrifuges, just to name a few.

PTFE – Diaphragms and Bellows

Thanks to their FDA approval and high chemical resistance, PTFE diaphragms and bellows are used for a wide range of applications. Other advantages of utilising our range of diaphragms and bellows include, exceptional fatigue resistance, high gas and liquid permeation resistance, suitability for sterilisation and they can also operate within a broad temperature range. Customers can visit the website for further information or alternatively, you can contact our customer service team directly.

PTFE – Spring Energized Seals

Our PTFE spring energized seals are mainly used for sealing reciprocating pistons and rods. As with many PTFE components, our seals possess properties which make them ideal for adverse environments. It is worth noting that each component within our spring energized seals can be tailored to your specific requirements. Just some of the applications that this product range can be used for include, paint spraying equipment, lab equipment, fuel injection systems and mixers.

Piston Rings

Our selection of piston rings are manufactured from PTFE and are utilised in oil-free compressors. Piston rings are particularly useful due to the recent trend for machines to run without lubrication. Our range of piston rings can be manufactured using a wide range of materials and with different joint types in mind, including straight joints, overlapped joints, scarf cut and gas-tight joints. For further information, please feel free to visit the website or you can contact us directly, by phone or email.

Memory Packings

We can offer PTFE memory packings which have been designed with low pressure applications in mind. Just some of the benefits to utilising these components include, chemical and thermal resistance, high wear resistance and excellent dry running performance, as well as many more. If you have any specific queries about these or any of our products, don't hesitate to get in touch. Alternatively, you can visit the website for details on products features.

Polyurethane Moldings

We can provide a comprehensive selection of polyurethane moldings with a wide range of applications in mind. We work with different grades of elastomer which can undergo processes such as casting, molding, machine turning, coating and spraying. We can also product specialist elastomers with excellent abrasion and wear resistance properties. Customers can visit the website for more information, including details about relevant applications and product features.

Elastomer Moldings

We can provide a selection of moldings which can be manufactured using both organic and inorganic elastomers. The mouldings themselves benefit from a wide range of innovative features which allow them to operate in a variety of environments. Just some of these features include, temperature resistance, chemical resistance and resistance to wear. As well as standard products, it is worth noting that we can manufacture completely bespoke solutions, if required. To find out more, please visit the website.

Vibration Control

We can provide a wide range of innovative vibration control products. Just some of the products within this range include hydraulic cushioning components and an extensive selection of elastomer dampers. This particular product range can offer a multitude of benefits, including movement damping, protecting and increasing the service life of components and reducing noise emissions. If you have any further questions, feel free to contact our customer service team directly.

Bearing Solutions

We can offer a range of bearing materials and products which can be used in reciprocating, bearing and swivel applications. Our bearing products can operate within extreme temperatures and do not require additional lubrication which makes them ideal for very specific environments. Just some examples of the products within this range include PTFE bearings, sintered bronze bearings, resin bonded polyester guide bands and machined aluminium bronze, as well as more.

Mill Lower Air Seal

The Mill Lower air seal has been designed for use in coal fired power stations and possesses a range of innovative features. The air seal was created in order to combat the specific problems found when using similar components. For example, previous seal systems incurred high maintenance costs and lacked reliability. With the installation of the Mill Lower air seal, users are guaranteed minimal maintenance, high durability and a long service life. For further information, don't hesitate to visit the website.

Magnetic Flow Filters

Our magnetic flow filters allow users to remove ferrous particles from advanced fluid conditioning. There are many benefits to utilising this form of technology, including a reduction in operation costs, a reduction in down time and a stable pressure. Magnetic flow filters are suitable fora variety of applications, including coal fired power stations, pharmaceutical manufacturing, mining and rubber manufacture, as well as many more. If you would like further information, feel free to visit the website.

Manuals & Brochures

Details

Info

| Registration Number: | 03493017 |

| VAT Number: | GB698 8208 68 |

| Registered at Companies House: | 15 January, 1998 (26 years and 4 months ago) |

| No of Employees: | n/a |

| Annual Turnover: | n/a |

| Parent Company: | FTL Seals Technology Ltd |

| Importers: | |

| Exporters: | |

| Company Type: |

|

Opening Times

| Monday | 09:00 AM - 05:30 PM |

| Tuesday | 09:00 AM - 05:30 PM |

| Wednesday | 09:00 AM - 05:30 PM |

| Thursday | 09:00 AM - 05:30 PM |

| Friday | 09:00 AM - 01:00 PM |

| Saturday | Closed |

| Sunday | Closed |

Questions

Additional Information

Brand & Trade Names

- Rodas Ram A patented cylinder designed and developed to replace the existing hydraulic/pneumatic cylinders used in PF mills used to pulverize coal at power stations and cement works worldwide.

Gallery

Financial Information

To view more detailed financial information for this company click here.

- Ideal Trainers Ltd

- TOOTING HOUSE LTD

- Inspired Solutions Bournemouth Ltd

- Flexible Conveyors

- VESTA TECHNICAL SERVICES Ltd

- Hydraulic Gauges

- Retractable Cables

- Lollo Fabula Ltd

- Mybe Entertainment Ltd

- Plastic Strapping

- Signs

- MILOU PROPERTY INVESTMENTS 4 LLP

- FREIGHT & TRANSPORT SOLUTIONS LTD

- Smart Gadgets Repairing Services

- CHANCTONBURY MANAGEMENT SERVICES LTD

- MOKO FILM Ltd

- WEMBLEY

- Glendale Mouldings Ltd

- Centre Lathes